PP Woven Bag Use for Fertilizer,Seed,Feed,Rice,Corn

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of woven bag:

This products is made by PP (Propene Polymer), it is used for Packing

Rice, flour, sugar, sand, fertilizer and so on. Other products available: Container bag, bulk bag, big bag, jumbo bag, woven fabric.

Specification of woven bag:

Material: Virgin PP

Weight: 40G/M2_200G/M2 AS customer's requirements.

CaCO3. Content: 5%-20%

Size: Width: From 30cm to 70cm

Length: As per Customer's requirements

Yarn: From 600 to 1, 500D, as per your requirements

Color: White, black, yellow, multi-colors, as per your requirements

Warp x weft: 10 x 10, 12 x 12, 14 x 14, as per your requirements

Line density: 111tex

Top: To heat cut and/or hemmed

Bottom: Single folded or double folded

Printing: On one side or both sides, in one color or multi-colors

Application:

The product are widely used in the storage and transportation of agricultural products, mineral products, chemical products, light industry products, etc

.

Packing of woven bag:

500PCS/bale, 1000PCS/bale. With plastic bag outside, then in container.

- Q:What is the material for edible fungus stick packing bag?

- HDPE bags, which are not high temperature resistant, can be sterilized at 104 degrees. Over this temperature, the contamination rate of pathogens will be increased.

- Q:Do vacuum packing bags have to be vacuum packed?

- To be exact, vacuum packing bags must have vacuum packaging machines to complete vacuum packaging. If you want to use vacuum packaging bags for non vacuum packaging (i.e. ordinary packing), you can also use them.

- Q:What are the requirements of the mark on the cement packing bag?

- Cement gradeCement is divided into strength grade: 1, Portland cement strength grade is divided into 42.5, 42.5R, 52.5, 52.5R, 62.5, 62.5R six levels. 2, ordinary portland cement strength grade is divided into 42.5, 42.5R, 52.5, 52.5R four grades.3. The strength grades of slag Portland cement, volcanic ash Portland cement, fly ash Portland cement and composite Portland cement are divided into 32.5 grades: six, 32.5R, 42.5, 42.5R, 52.5 and 52.5R.

- Q:Which kind of transparent vacuum packing bag 16 wire and 24 wire?

- The so-called silk is a unit, a trace of =0.01mm, from this point of view, the bag is thicker, the more difficult to leak, so the 24 wire than the 19 wire better.

- Q:What material is the packing bag for pure milk, please?

- Lining, Xiong Xiaoli. Study on the separation of aluminum plastic paper composite packaging. Packaging engineering, 2008, 29 (12): 56-58.lixixiao2 (in TA) food grade polyethylene chen.1fan (TA station) composite layer of aluminium metal and linear PE, the middle layer there should be consistent with FDA zznjut (station link TA) composite and 100% more than one layer of polymer should be PE, the rest of the aluminum foil paper, duanyanjian (station TA) aluminum composite paper plastic bag

- Q:Can the meat with plastic packing bag be pressed directly with a pressure cooker?

- It is better not to use a plastic bag directly with a pressure cooker heating, because it is said that plastic bags at high temperatures easy to precipitate toxic substances, so remove plastic bags and then heating for good, so as not to affect the health.

- Q:What are the soft and hard sides of plastic bags? Material or process technology?

- On the basic price will be a little higher, the brittle is generally PP or PET is done, some relatively low grade. Soft is generally made of multi-layer coextrusion film, barrier, and feel good. This soft about 27000 yuan / ton, while the PP film generally as long as 17000 yuan / ton, ten thousand tons a difference.

- Q:What's the packing of the air in the food package?

- For example, our common bag of potato chips, which is mostly nitrogen N2, a gas filling packaging is fat, on the one hand is the replacement of the original air bag and prolong the shelf life; on the one hand, there is a large amount of gas support chips during transportation and storage, can also be to reduce the impact of fragmentation. You certainly don't want to buy potato chips all over it.

- Q:Express carton packaging, plastic packaging should be how to deal with?

- Express packaging bags can be used as garbage bags, now online shopping people, in addition to vegetables, fruits this difficult to preserve things, a considerable portion of daily necessities are purchased from the internet. However, the excessive packaging of online shopping packages once troubled people. "Online shopping, a clothing is generally at least two layers of packaging, and the first is the clothes factory comes with transparent plastic bags, and there is a layer of express bags attached to the courier."." Some time ago, "double 11", a friend bought three clothes and a set of speakers, these days have gradually arrived, and summed up a total of eight large plastic bags and two cartons.

- Q:What are the characteristics of a good package?

- According to the statistics of the foreign trade department, because of the backward packaging of export commodities, China has reduced the foreign exchange earnings by at least 10% per year. This shows that the good packaging design for the importance of national economic development.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

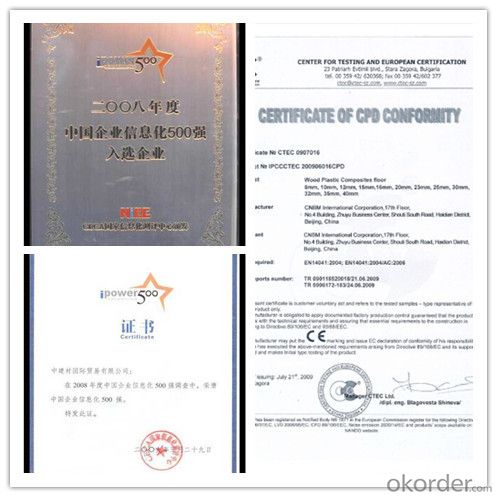

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP Woven Bag Use for Fertilizer,Seed,Feed,Rice,Corn

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords