PP Spunbonded Nonwoven Fabric cloth in hospital and others

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

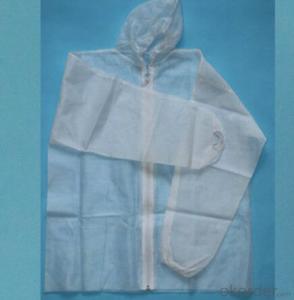

PP Spunbonded Nonwoven Fabric cloth protect from desease

is used to protect the t can protect the doctors or workers safely and protect them from desease.

Specification of PP Spunbonded Nonwoven Fabric cloth protect from desease:

Feature Waterproof, Mothproof, Eco-friendly, Non-toxic, Breathable, Anti-Bacteria

Width | 0.4--3.2M |

Color | Any color available |

Roll Length | According to your requirement |

Technics | Nonwoven |

Nonwoven Technics | Spunbonded |

Pattern | Yarn Dyed |

Weight | 9-200GSM |

Style | Plain |

Feature | Waterproof,Mothproof,Eco-friendly,Non-toxic,Breathable,Anti-Bacteria |

Certification | ISO9001 |

Usage | Agriculture,Indrustry,Construction,Packaging,Home-textitle, etc |

MOQ | 1Ton/1000KG |

Payment Terms | T/T or L/C |

Delivery Time | Within 7-15 days |

Packaging Detail | Plastic film in roll |

Place of Origin | Shandong,China |

Loading of Port | Qingdao |

Sample | Free samples are available |

Packing of PP Spunbonded Nonwoven Fabric cloth protect from desease:

Each roll is wrapped in a plastic bag with label specification with paper tube inside .

Feature Waterproof, Mothproof, Eco-friendly, Non-toxic, Breathable, Anti-Bacteria

- Q:What are the installation guidelines for geotextiles used in erosion control blankets?

- The installation guidelines for geotextiles used in erosion control blankets typically involve the following steps: 1. Site preparation: Ensure that the area where the erosion control blanket will be installed is properly graded and free of any debris or vegetation. 2. Unroll the geotextile: Start by unrolling the geotextile fabric along the slope or area where erosion control is needed. Make sure to overlap the fabric by the specified amount to ensure complete coverage. 3. Secure the fabric: Use stakes or landscape pins to secure the geotextile to the ground, especially at the edges and corners. This will prevent it from shifting or being displaced during installation or heavy rainfall. 4. Seam connection: If multiple rolls of geotextile fabric are required, ensure that they are properly overlapped and securely connected using a recommended seam connection method. This will ensure a continuous and seamless coverage. 5. Anchoring: In certain cases, additional anchoring may be required to provide extra stability. This can include using sandbags, rocks, or other suitable materials along the edges or across the surface of the geotextile fabric. 6. Vegetative cover: If the erosion control blanket is designed to support vegetation growth, follow the recommended guidelines for seed or plant installation. This may involve spreading seeds or planting live vegetation through the geotextile fabric. It is important to note that these guidelines may vary depending on the specific erosion control blanket and geotextile manufacturer, as well as the site and project requirements. It is always recommended to refer to the manufacturer's installation instructions and consult with a professional engineer or erosion control specialist for proper installation and best results.

- Q:Seepage geotextile and impervious geomembrane

- It is generally believed that the individual geotextile does not have the anti-seepage effect, the main assessment index is the permeability coefficient, the general geotextile coefficient is higher than the ordinary soil, about 0.01-0.001 look, but the geotextile and rubber, Asphalt, plastic combination will form a water-impermeable composite, anti-seepage effect increased by 10 times, and asphalt, rubber combined into a waterproofing membrane such as sbs, etc., and plastic is generally polyethylene, polyvinyl chloride, eva (standard name is Geomembrane) is a combination of impermeable geomembrane or composite geomembrane, because the composite white geotextile outside the protective effect, so the project is also called impermeable geotextile. Therefore, the two are essentially not much difference, but the argument is different. Waterproof board is also called geomembrane, customary to> 0.8mm thick geomembrane called waterproof board, & lt; 0.8mm called geomembrane, it is based on high molecular polymer as raw material made of impermeable material , Divided into homogeneous waterproof board and composite waterproof board

- Q:Can geotextiles be used in the protection of retaining walls?

- Yes, geotextiles can be used in the protection of retaining walls. Geotextiles are often used as a filter or separation layer behind retaining walls to prevent the migration of fine soil particles and provide drainage. They help in distributing the load and reducing the pressure on the wall, increasing its stability and lifespan.

- Q:What is the role of the laying of geotextiles at the bottom of the grassland?

- From the soil and soil, fixed slope protection, anti-erosion, anti-filter (over the water, but soil) and other effects, I professional production geotextile, geomembrane and other products, wish smooth

- Q:Can geotextiles be used in underground storage tank installations?

- Yes, geotextiles can be used in underground storage tank installations. Geotextiles are often used as a protective barrier between the tank and the surrounding soil to prevent contamination and provide stability.

- Q:What are the factors to consider when selecting a geotextile?

- When selecting a geotextile, there are several factors to consider. Firstly, the application or purpose of the geotextile is important. Different geotextiles are designed for specific functions such as filtration, separation, drainage, or reinforcement. Understanding the specific requirements of the project and matching them with the appropriate geotextile is crucial. Secondly, the site conditions need to be evaluated. Factors such as soil type, slope stability, groundwater levels, and expected loads or stresses should be considered. The geotextile should be able to withstand these conditions and provide the necessary performance. Thirdly, the durability and longevity of the geotextile should be assessed. Factors like UV resistance, resistance to chemicals or biological degradation, and the expected lifespan should be evaluated to ensure that the selected geotextile can withstand the anticipated environmental conditions. Additionally, the installation and maintenance requirements should be taken into account. Some geotextiles may require specialized equipment or techniques for installation, while others may need periodic monitoring or maintenance. Understanding these requirements is essential for a successful project. Lastly, cost-effectiveness is an important factor. While it is crucial to select a geotextile that meets the project requirements, it is also necessary to consider the associated costs. Evaluating the initial cost, as well as the long-term benefits and potential savings, helps in making an informed decision. In summary, the factors to consider when selecting a geotextile include the specific application, site conditions, durability, installation requirements, and cost-effectiveness.

- Q:How do geotextiles affect construction site safety?

- Geotextiles play a crucial role in enhancing construction site safety by acting as a barrier against soil erosion, stabilizing slopes, and improving overall ground stability. These textiles prevent sediment runoff, control water flow, and reinforce soil structures, reducing the risk of accidents and potential damage to the construction site. Additionally, geotextiles aid in the filtration and drainage system, preventing waterlogging and enhancing the stability of foundations, ultimately ensuring a safer working environment for construction workers.

- Q:How do geotextiles help with filtration in drainage systems?

- Geotextiles assist with filtration in drainage systems by acting as a barrier that allows water to pass through while preventing the passage of fine particles and sediment. This helps to maintain the integrity and effectiveness of the drainage system by preventing clogging and promoting efficient water flow.

- Q:Long-term exposure to geotextiles on the human body what harm?

- Geotextile material is mostly polyester, and the essence of polyester clothes the same. There are mineral water bottle material is also PET polyester polyester sheet. Polyester has been widely used in our lives, no radiation, no pollution, no poison. Long-term close contact with the geotextile on the body without injury. So you do not have to worry.

- Q:What are the different geotextile installation techniques for roadways?

- There are several different geotextile installation techniques for roadways, including the overlay method, the trench method, and the sandwich method. - The overlay method involves placing the geotextile directly on top of the existing soil or subgrade before adding the new road material, such as asphalt or concrete. This technique helps to separate the soil layers and prevent the mixing of materials, providing stability and reducing the risk of road failure. - The trench method involves excavating a trench along the road alignment and placing the geotextile in the trench before backfilling it with soil or aggregate. This technique is commonly used for drainage applications, as the geotextile acts as a filter to prevent fine particles from clogging the drainage system, while allowing water to flow through. - The sandwich method is a combination of the overlay and trench methods. It involves placing a layer of geotextile between the existing soil and the new road material, as well as placing another layer of geotextile on top of the new road material. This technique provides additional reinforcement and separation, enhancing the overall performance and durability of the roadway. Overall, the choice of geotextile installation technique depends on the specific requirements and conditions of the road project, such as soil type, traffic load, and drainage needs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP Spunbonded Nonwoven Fabric cloth in hospital and others

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords