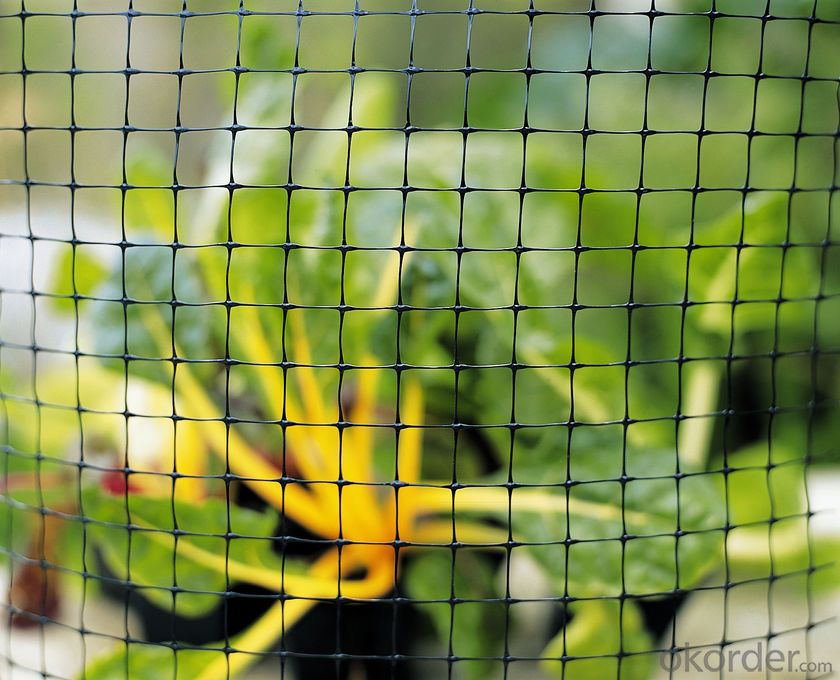

PP Plastic Animal Fence From Manufacture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic netting plastic mesh breeding mesh

1. Plastic Plain Netting

Colour:white,black,blue and green, client's requirement.

2. Deer fence introduction:

Deer fencing is a very high strength, lightweight, 3.6ft to 7.3ft high deer fence manufactured from high strength polypropylene BOP plastic netting. Deer have a tendency to forage over large areas and the cost effective deer fencing offers a very effective deer control barrier.

The deer fence is black, UV stabilised and rot proof and unobtrusive as it merges into it's background. Deer fencing is very quick and easy to erect and each roll weighs less than 15kg. The Deer Netting should be installed by battening to the fencing posts to ensure the mesh filaments are not damaged.

3. Features of the deer neeting fence:

Deer fence is easy to erect and install

Plastic netting has a mesh hole size of 0.06" ,0.08",0.18",0.19"

The BOP plastic netting has a high tensile strength

Plastic mesh is UV stabilized and chemical resistant

Deer fencing rolls are lightweight

Deer fencing is a very high strength, lightweight 1.8m high Deer fence manufactured from polypropylene.

Deer fencing net is supplied on a 100m long roll

4. Deer Fence Features:

1). Low cost, while has superior strength

2). Has anti-tearing and friction capability

3). Wide range of product availability, some other mesh sizes and weights can also produced as per customers' requirements.

5. Package/Payment/Delivery:

Package: Usually packed by rolls in plastic film bags with labels inside and then loosely loaded in the container

6. FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q:What is the expected lifespan of geotextiles?

- The expected lifespan of geotextiles can vary depending on factors such as the material used, the specific application, and the environmental conditions. However, on average, geotextiles are designed to have a lifespan of at least 25 to 30 years.

- Q:How do geotextiles help with soil stabilization in slope stabilization projects?

- Geotextiles play a crucial role in soil stabilization during slope stabilization projects. They are designed to be placed between layers of soil to enhance their structural stability. Geotextiles act as a barrier, preventing soil erosion and promoting water drainage. By providing reinforcement, they distribute the load across a wider area, reducing the pressure on the slope and minimizing the risk of landslides. Additionally, geotextiles help to retain moisture in the soil, which aids in vegetation growth, further strengthening the slope. Overall, geotextiles are an effective solution for soil stabilization in slope stabilization projects.

- Q:Can geotextiles be used for soil stabilization?

- Yes, geotextiles can be used for soil stabilization. Geotextiles are commonly used to reinforce and stabilize soil by providing strength, preventing erosion, and promoting drainage. They are often used in various civil engineering applications such as road construction, embankments, and retaining walls to improve the stability and longevity of the soil.

- Q:What are the different geotextile installation techniques in separation?

- The different geotextile installation techniques in separation include direct placement, trench installation, and overlay installation. Direct placement involves laying the geotextile directly on the subgrade or soil surface, providing separation between different layers of soil or aggregate. Trench installation involves placing the geotextile in a trench dug along the separation line, then backfilling the trench with soil or aggregate. This technique is commonly used in applications like road construction. Overlay installation involves placing the geotextile on top of an existing surface, such as an old road, to provide separation between the existing surface and a new layer of soil or aggregate. Each installation technique has its advantages and is chosen based on the specific project requirements.

- Q:Can geotextiles be used in bridge construction?

- Yes, geotextiles can be used in bridge construction. Geotextiles provide additional support, reinforcement, and stabilization to bridge structures. They help in preventing soil erosion, managing water drainage, and improving the overall stability and durability of the bridge.

- Q:How do geotextiles help with soil confinement in erosion control mats?

- Geotextiles help with soil confinement in erosion control mats by acting as a barrier that prevents soil particles from being washed away by water or wind. The geotextiles stabilize the soil by providing a physical barrier that holds the soil in place, reducing erosion and promoting vegetation growth.

- Q:What are the considerations for geotextile installation?

- Some considerations for geotextile installation include site preparation, proper anchoring techniques, selecting the appropriate geotextile material for the specific application, ensuring proper overlap and seam strength, and proper maintenance and inspection of the installed geotextile.

- Q:How do geotextiles contribute to the performance of geosynthetic tubes?

- Geotextiles play a crucial role in enhancing the performance of geosynthetic tubes by providing reinforcement, filtration, and separation functions. They help to distribute the stress and reduce the potential for puncture or tearing, thus improving the overall strength and stability of geosynthetic tubes. Additionally, geotextiles act as effective filters, preventing the migration of fine particles while allowing water or gases to pass through. This filtration capability helps maintain the integrity and functionality of the geosynthetic tubes. Finally, geotextiles aid in separating different materials or soil layers, preventing the mixing or contamination of materials and ensuring the optimal performance of geosynthetic tubes.

- Q:Woven geotextile is not considered a spinning geotextile

- Woven geotextile is made of textile technology is a spinning geotextile.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP Plastic Animal Fence From Manufacture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords