PP,PE,PVC,ABS,PET Plastic Extruding Sheet Production Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP,PE,PVC,ABS,PET Plastic Extruding Sheet Production Line

Features:

–This production line is suitable for PP,PS,PE,ABS and other materials.

–If exchanging the machine model head,PP,PE,PVC,ABS,PET,PMMA and PC plate material can also be processed.

–If adding a drying device,PET sheet material is also able to be processed.

Detailed Product Description:

This production line is mainly composed of extruders, machine head, three-roll calendar machine, bracket tractor and double-station fetching machine. It is mainly used for manufacturing PET, PP and PS plastic membrane and plus the changed molds, it can manufacture many kinds of thermoplastic sheets.

Main Technical Parameter:

| Screw diameter | SJZ-80/156 | SJZ-92/188 |

| Motor power | 55kw | 110kw |

| Thickness of sheet | 0.2-3mm | 0.2-3mm |

| Width of sheet | 1200mm,1500mm | 1200mm,1500mm |

| Output | 300kg/h | 500kg/h |

| Practical power | 120kw | 160kw |

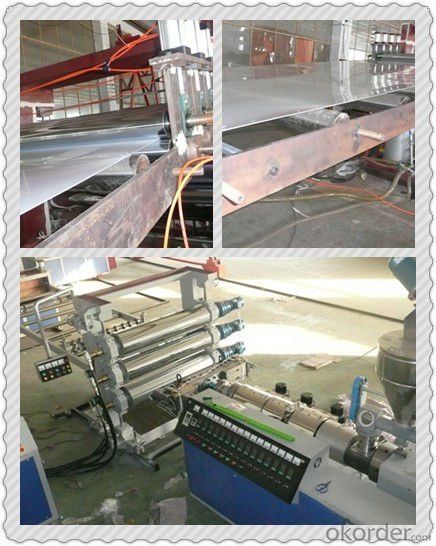

Pictures:

- Q:How much do you need for it? How about the raw material?

- Raw materials can be selected according to the needs of the market, including PVC, PE etc..

- Q:Plastic machinery plastic pellet production process _ particles recycled plastics particles

- 16 、 domestic garbage plastic particle flotation device17 、 granular plastics dehumidification drying system18. Methods for the preparation of colored plastics or colored polymeric particles19. A method for producing a particulate formulation that is soluble in a plastic stain20. The spherical particles are prepared by the plastic melt21. Lactam based pigments and their use in the production of colored plastics or polymeric colored particles22. Methods for producing colored plastics or polymeric colored particles23, columnar particles of plastic compound additive, production process and application thereof24, manufacturing method of waste plastic particles and thermal decomposition method thereof25. The preparation of colored plastic or polymer dye granules26. Azo dyes, their preparation methods and their applications in the manufacture of colored plastics or polymers, colouring particles, and dyeing or printing of hydrophobic fiber materials27, pyridine ketone dye, process for the preparation thereof, and use in the manufacture of colored plastic or polymer colored particles28, pyridine ketone dye, process for the preparation thereof, and use thereof in the preparation of colored plastics or polymeric colorant particles29. Coating compositions of thermoplastic resin particles for forming foam containers30. Adsorption dryer for plastic material particles

- Q:What are the features of plastic injection gears and machined plastic gears?

- Injection of better, smooth finish, smoothness can be done on the mold, the strength is also good. When machining, some of the transmission, the edge may be very difficult to process, very beautiful

- Q:What kind of equipment do we need? How much is the approximate cost? Seek your heroes guidance and guidance!

- Equipment include: film blowing machine, bag machine, punching machine, printing machine, etc., to invest one hundred thousand up and down, but also need a few tons of raw materials as a turnover, and then start production, I do not know very well, just listen to someone else said...

- Q:What plastic products do you have and what's the use of it?

- in the mechanical industry made of plastic transmission gears, bearings, bearing and many parts to replace metal products; plastic pipes, as in the chemical industry in a variety of containers and other anti-corrosion materials;

- Q:What plastic products are made out of machines? Is it an injection molding machine?

- According to the process, there are many kinds of processing equipment, not only the injection molding machine, as well as extruder.

- Q:Processing method of PPS plastic

- 3, the automobile industry: PPS for automobile industry accounted for about 45%, mainly used in automotive functional parts; ignition, heater, vaporizer, clutch, gearbox, gear box, bearing bracket, lamp, bumper, fan, exhaust system and mirror and lamp seat parts. The utility model can be used for producing an exhaust cylinder, a circulation valve, a water pump impeller, a pneumatic signal adjuster, etc. in place of the metal. 4, household appliances: hot air dryer, hair curler, hair dryer, hair curler, microwave ovens, coffee pots, clothes dryers, electric irons, rice cookers and other protective coatings and parts. 5 、 chemical industry: PPS has good adhesion and corrosion resistance, it is very suitable for chemical equipment lining.Four. Material drying processTemperature: 100~105 DEG CTime: 3hr2 、 injection molding process1) die temperature: 60-80 DEG C2) material barrel temperature: front section: 220~260 centigrade middle section: 290~310 DEG C, rear section: 300~320 DEG CNozzle: 290~300 DEG C3) injection molding pressure: 60~70Mpa4) injection speed: medium speed5) injection molding time: according to the size of the workpiece to determine, in order to fill the mold, and the surface of the basic cooling is preferred

- Q:Who knows Guangdong province processed waste plastic particles Factory where. Thank you

- Guangdong is very large! Where is there, where is the friend? Guangdong is more than Shunde, the most prosperous town, I work here in Guangdong, Zhongshan Province plastic granulation machinery factory.

- Q:I would like to open a small plastic daily necessities processing factory, want to buy such as plastic buckets, plastic basins, plastic small bowl machinery!

- Similar processing machinery, you can go to the machine processing and other similar websites to check

- Q:In Shengze where you can find what rags processed into a plastic factory

- You mean it woven rags! Use a plastic granulator.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP,PE,PVC,ABS,PET Plastic Extruding Sheet Production Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches