PP Non Woven Geotextile Manufactory with High Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Geotextile

Good flexibility, permeability, filtration, sepatation and easy for construction.

Application of Geotextile

CMAX Geotextile has excellent permeability, acquired, durablity, which can be widely used in railway, highway, movement hall, dams, hydraulic structures, hence hole, coastal shoal,reclamation, environmental protection and other projects.

The main products are Synthetic staple fibers needlepunched non woven geotextiles and slit and split film yarn woven geotextiles.

Specifications:100GSM-1500GSM

length:50m-100m

width:1m-8m

material:100%PP

Packaging Details: pp woven bags or at your request

Delivery Detail: 15 days

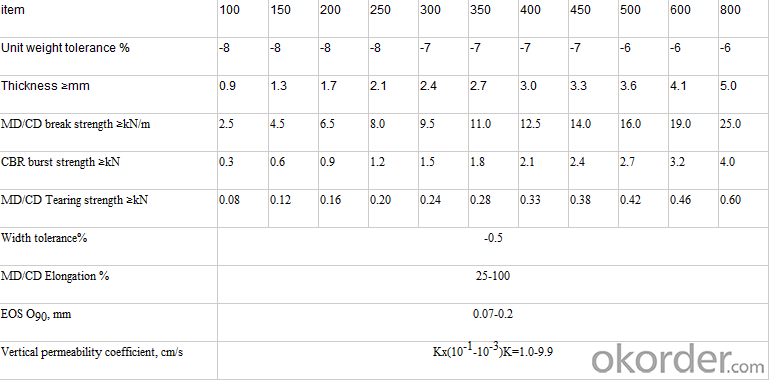

Technical Specification

FAQ

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:Geotextile 100 meters a roll is about how much diameter

- Look at geotextile specifications, look at the thickness of the. Normal it 20-45 cm

- Q:The amount of geotextile drained pipe drape

- According to the two sides agreed by the measurement method, such as by the extension of the package or the expansion of the area can be calculated, you can also agreed to package a tube how much money. Generally calculated by the expansion of the area is more reasonable, because the size of the pipeline.

- Q:Are geotextiles resistant to fire?

- Yes, geotextiles are generally resistant to fire. They are typically made from materials that have high melting points and are designed to withstand exposure to heat and flames without catching fire or spreading flames. However, it is important to note that the level of resistance may vary depending on the specific type and composition of the geotextile.

- Q:What are the different factors to consider when selecting a geotextile?

- When selecting a geotextile, several factors need to be considered. These include the project's specific requirements, such as the expected load and traffic conditions, the soil type and composition, the desired lifespan of the geotextile, and any environmental considerations. Additionally, factors such as the geotextile's strength, permeability, and compatibility with other materials used in the project should also be taken into account.

- Q:What are the different geotextile erosion control products available in the market?

- There are several geotextile erosion control products available in the market, including geotextile mats, geotextile tubes, geotextile blankets, and geotextile grids. These products are designed to prevent soil erosion by providing stability, filtration, and reinforcement to the soil. Geotextile mats are typically used for slope stabilization, while geotextile tubes are commonly used for shoreline protection and dewatering applications. Geotextile blankets are used for erosion control on steep slopes and channels, and geotextile grids are often used for soil stabilization in areas with heavy traffic or high loads.

- Q:How do geotextiles prevent soil erosion on slopes?

- Geotextiles prevent soil erosion on slopes by providing a stable and protective layer that helps retain the soil in place. These synthetic materials are placed on the slope and act as a barrier, preventing the soil from being washed away by rainfall or runoff. Geotextiles also promote proper drainage, allowing excess water to flow through while retaining the soil particles. This helps to maintain the integrity of the slope and reduce erosion caused by water movement.

- Q:What kind of geotextile is used to repair the road?

- Call one three seven to understand three one two one two to ensure that the quality of price satisfaction

- Q:Can geotextiles be used in coastal protection systems?

- Yes, geotextiles can be used in coastal protection systems. They are often used as a part of erosion control measures, such as beach nourishment or seawall construction. Geotextiles can help to stabilize coastal slopes, prevent soil erosion, and provide a barrier against wave action. Their permeable nature allows for water drainage while still offering effective protection against coastal erosion.

- Q:Can geotextiles be used in coastal erosion control projects?

- Yes, geotextiles can be used in coastal erosion control projects. They are often employed as a part of erosion control systems to stabilize the soil and prevent erosion in coastal areas. Geotextiles are permeable fabrics that are placed on the ground or underwater to reinforce and protect the soil, while allowing water to pass through. They can help in maintaining beach profiles, preventing sediment loss, and reducing wave energy, thus providing effective coastal erosion control.

- Q:What are the materials used in geotextile production?

- Geotextiles are typically produced using a variety of materials, including synthetic fibers such as polypropylene, polyester, and polyethylene. These materials are chosen for their durability, strength, and resistance to environmental conditions. Natural fibers like jute and coir can also be used in certain geotextile applications. Additionally, some geotextiles may incorporate additives or coatings to enhance their performance and stability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP Non Woven Geotextile Manufactory with High Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords