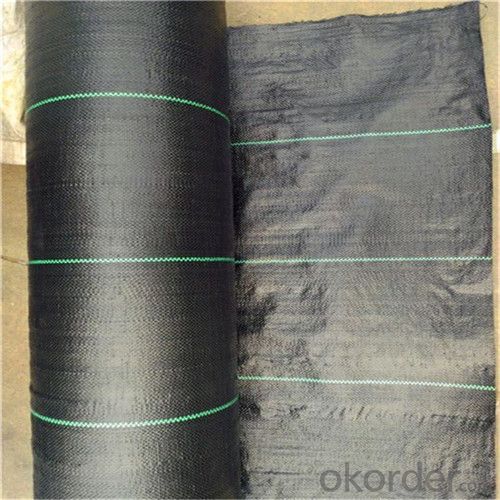

PP Landscape Fabric// Geotextile for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Geotextile Introduction

PP Geotextiles are composed from synthetic polypropylene/polyester fibres through a mechanical process of needling the fabric and adding, when necessary, a thermo fused process, resulting in a uniform porous structure with excellent tensile strength and chemical deterioration.

PP Geotextile Specification

1) Weight / Mass: 75g/m2-400g/m2 .

2) Width: Within 8 m (1m-8m)

3) Length: 50m-100m/roll (as request)

4) Material: PP

5) Color: Black , white , grey, others

6) The biggest geotextile manufacturer/factory in China for many years . The equipment is introduced from Germany.

7) This geotextile can be made of polypropylene (PP).

8) The mass is available from 75g/m2 to 400g/m2 and the width available from 1.0m-8m, monolayer or multilayer (reinforcement geotextiles), long fiber or short fiber.

9) Color: all kinds of color are available. The annual production ability is 10 million square meters.

10) The fabric can also be heat treated by infrared at customer's requirements. Our geotextile are UV stabilized to give protection against aging under exposure to natural ultra-violet light.

PP Geotextile Application

1) Filtration

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation:

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3 )Reinforcement:

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4 )Protection

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q:What are the specifications for geotextiles in coastal protection projects?

- The specifications for geotextiles in coastal protection projects typically include factors such as the material type, tensile strength, permeability, and UV resistance. Additionally, the specifications may also outline requirements for installation methods and durability to ensure the geotextiles effectively mitigate erosion and provide long-term stability to coastal areas.

- Q:How do geotextiles help in reducing soil compaction?

- Geotextiles help in reducing soil compaction by distributing the load from heavy vehicles or equipment over a larger area, thereby minimizing the pressure exerted on the soil. This prevents the soil particles from being compressed tightly together, allowing for better soil structure and drainage.

- Q:Can geotextiles be used in rockfall protection works?

- Yes, geotextiles can be used in rockfall protection works. Geotextiles are often employed as a barrier or reinforcement material in these types of projects. They can help to prevent the displacement of rocks and soil, enhance the stability of slopes, and provide additional support to rockfall protection structures.

- Q:How can we file in the Water Resources Department? I was doing hydraulic works with geotextiles, geogrids, gabion, gabbin.

- Water geotechnical engineering geotextile, geogrid, gabion, Geben network should belong to the geotextile material series, you can refer to the required record of the Department of Water Resources on the geotechnical industry for the record requirements. At present, the provinces and cities of the record requirements are not the same, you want to record in which provinces and cities will go to the provincial and municipal water conservancy department official website to see the specific requirements, the Internet will generally have publicity, you can call the consultation. The general information required for the record includes: business license, tax registration certificate, organization code certificate, national industrial production license, safety production license, ISO9000 / ISO certification, legal personality certificate, power of attorney, contract copy in recent years Three-year financial audit report, the company's basic household certification.

- Q:Waterproof geotextile market demand prospects?

- Supply geotextile, geomembrane, composite geomembrane and other geotechnical materials. Market prospects are excellent. Geotechnical material manufacturers to answer your questions

- Q:Do you have a geotextile bed?

- Well, geotextile material is not environmentally friendly

- Q:Can geotextiles be used in tunnel construction?

- Yes, geotextiles can be used in tunnel construction. Geotextiles are often used as reinforcement materials to improve the stability and strength of tunnel walls. They help to prevent soil erosion, control water flow, and provide additional support to the tunnel structure.

- Q:What are the key differences between woven and nonwoven geotextiles?

- The key differences between woven and nonwoven geotextiles lie in their manufacturing processes and physical characteristics. Woven geotextiles are made by interlacing yarns or fibers together to create a stable and strong fabric. On the other hand, nonwoven geotextiles are produced by bonding or felting fibers together without any weaving process. In terms of physical characteristics, woven geotextiles generally have higher tensile strength and puncture resistance due to their interlaced structure. They also offer better filtration properties as the open spaces between the woven yarns allow for effective water flow. Nonwoven geotextiles, however, have a higher permittivity, meaning they have a greater ability to allow water to pass through. Another notable difference is their durability. Woven geotextiles tend to be more resistant to UV degradation and offer better long-term performance, making them suitable for applications that require high strength and stability over time. Nonwoven geotextiles, although less durable, are often used for short-term projects or where filtration and separation are the main requirements. Overall, the choice between woven and nonwoven geotextiles depends on the specific application and desired properties. Woven geotextiles are typically favored for their strength and longevity, while nonwoven geotextiles are preferred for their filtration capabilities and cost-effectiveness in certain applications.

- Q:What are the different guidelines for geotextile installation in erosion control projects?

- There are several guidelines for geotextile installation in erosion control projects. Firstly, it is important to properly prepare the soil surface by removing all vegetation, debris, and loose soil. The geotextile should then be placed directly on the prepared surface, ensuring that it is smooth and free of wrinkles or folds. It is crucial to overlap the geotextile seams by the manufacturer's recommended distance and secure them with staples or other appropriate fasteners. Additionally, the geotextile should be anchored using anchor trenches or pins to prevent movement. Finally, proper maintenance and inspection of the geotextile should be carried out regularly to ensure its effectiveness in erosion control.

- Q:Are geotextiles commonly used in landfills for leachate collection?

- Yes, geotextiles are commonly used in landfills for leachate collection.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP Landscape Fabric// Geotextile for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords