PP Fiber for Concrete Reinforcement Usage

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Fiber Introduction

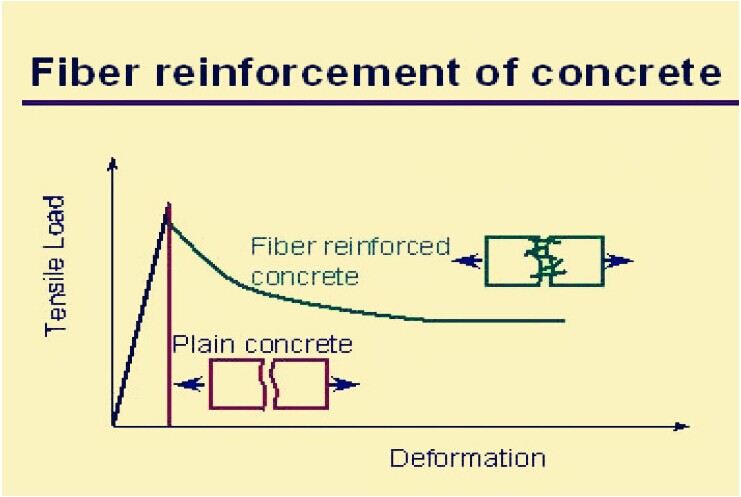

Polypropylene fiber also called PP fiber, is a new type of reinforcing and crack-resistant building material for bitumen concrete reinforcement. It is produced by special technique.With polypropylene as its raw material,fiber-mesh is produced by special technology.It appears net-like structure with many monofilaments connected.

The horizontal structure in monofilament can be destroyed in the course of the stirring owng to friction and rubbing,and the monofilament or net like structure will fully stretch, thus the concrete is reinforce by a great number(more than 7 million pieces per cubic meter) of polypropylene fibers.

Features of PP Fiber for Concrete Reinforcement

pp fiber is also called engineering fiber, concrete fiber, anti-cracking fiber, synthetic fiber or plastic fiber.

1).Prevention of the mortar’s contraction crack.

2).Improvement of the wall’s anti-shock and resistance to stripping.

3).Increasing of anti-permeability of wall.

4).Strengthen resistance to freezing and thawing.

5).Improve the ability of protection of reinforcement.

6).Prevent mud crack and crack propagation of mortar.

7).Substitute for steel mesh.

Technical Data of PP Fiber for Concrete Reinforcement

Name | 100%pp fiber |

Raw Material | Polypropylene/pp |

Type | Monofilament |

Fiber Dia | 10-45um |

Tensile Strength | ≥500Mpa |

Size | 6-48mm |

Crack Elongation | 15-25% |

Density | 0.91g/cm3 |

Melting Point | 160---170°C |

Resistance to Acid, Alkali | Strong |

Water Absorbency | No |

Package of PP Fiber for Concrete Reinforcement

1kg/plastic bag,20bags/pp woven bags

Product effect of PP Fiber for Concrete Reinforcement

FAQ

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples if you need.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world

- Q:Can earthwork products be used for waterway management?

- Yes, earthwork products can be used for waterway management. Earthwork products such as erosion control blankets, geotextiles, and geogrids can help stabilize soil and prevent erosion along waterways. These products can also be used to construct channels, levees, and dams, which are important for managing and controlling water flow in rivers, streams, and other water bodies.

- Q:Are earthwork products suitable for agricultural applications?

- Yes, earthwork products such as soil, gravel, and mulch can be highly suitable for agricultural applications. They can be used for activities like land leveling, soil amendment, drainage improvement, and erosion control, which are essential in maintaining healthy and productive agricultural fields. Additionally, earthwork products can help improve water retention, nutrient availability, and overall soil health, contributing to successful crop growth and maximizing agricultural yields.

- Q:Are earthwork products resistant to weathering?

- Earthwork products, such as soil, rocks, and gravel, are generally resistant to weathering to some extent. However, their resistance may vary depending on the specific type of material and the prevailing weather conditions. While some earthwork products may be more durable and less prone to weathering, others may be more susceptible to erosion, degradation, or disintegration over time due to exposure to wind, rain, temperature changes, and other environmental factors. Therefore, it is important to consider the specific characteristics and composition of the earthwork product in question when assessing its resistance to weathering.

- Q:Are earthwork products suitable for underground storage systems?

- Yes, earthwork products can be suitable for underground storage systems. These products, such as geotextiles and geomembranes, are often used in the construction of underground storage systems to provide reinforcement, stability, and prevent leakage. They can effectively withstand the pressure exerted by the surrounding soil and water, ensuring the integrity and durability of the storage system.

- Q:What are the different design options available for earthwork products?

- There are several design options available for earthwork products, including retaining walls, erosion control systems, slope stabilization techniques, and stormwater management solutions. These options can vary in terms of materials used, construction methods, aesthetic appeal, and functionality. Ultimately, the choice of design option depends on the specific site requirements, project goals, and budget constraints.

- Q:What are the specific applications of geosynthetics in earthwork projects?

- Geosynthetics have various specific applications in earthwork projects, including soil stabilization, erosion control, reinforcement, drainage, and filtration. They can be used to improve the strength and stability of soils, prevent erosion on slopes and embankments, provide structural support for retaining walls and embankments, and enhance drainage systems by facilitating water flow while preventing the loss of fine particles. Additionally, geosynthetics can be employed for separating different soil layers, protecting geomembranes from punctures, and reducing the amount of fill material required for construction, making them versatile and essential components in earthwork projects.

- Q:How are geotextile mats used in erosion control on coastal cliffs?

- Geotextile mats are used in erosion control on coastal cliffs by being installed on the slopes to stabilize the soil and prevent erosion. These mats provide a protective layer that helps in retaining moisture, reducing surface runoff, and increasing the vegetation growth. Additionally, they help to absorb and dissipate the energy of waves and tides, minimizing the impact of water on the cliff face. Overall, geotextile mats play a crucial role in maintaining the stability and protection of coastal cliffs against erosion.

- Q:How can geosynthetic panels be used in bridge abutments?

- Geosynthetic panels can be used in bridge abutments to provide reinforcement and stability. These panels are typically made of high-strength materials like geotextiles or geogrids, which can be layered and attached to the abutment walls. By adding geosynthetic panels, the abutment gains increased load-bearing capacity and improved resistance to lateral forces. Additionally, these panels can help with soil erosion control and provide a barrier against potential water infiltration. Overall, geosynthetic panels offer a cost-effective and efficient solution for enhancing the performance and lifespan of bridge abutments.

- Q:How do earthwork products contribute to sound barrier construction?

- Earthwork products, such as soil, gravel, and rocks, play a crucial role in sound barrier construction. These materials are used to build embankments or berms, which act as physical barriers to absorb, reflect, and redirect sound waves. By strategically placing and shaping these earthwork products, sound barriers can effectively reduce noise pollution from highways, railways, or other sources, enhancing the overall acoustic environment and improving the quality of life for nearby communities.

- Q:What are the advantages of using geogrids in earthwork projects?

- Geogrids offer several advantages in earthwork projects. Firstly, they provide reinforcement to the soil, increasing its load-bearing capacity and stability. This helps in constructing structures on weak or unstable soils. Additionally, geogrids minimize soil erosion by stabilizing slopes and retaining soil particles. They also enhance the performance and longevity of paved surfaces by reducing cracking and rutting. Moreover, geogrids are cost-effective, easy to install, and environmentally friendly alternatives to traditional methods. Overall, the use of geogrids in earthwork projects improves structural integrity, reduces maintenance costs, and promotes sustainable construction practices.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP Fiber for Concrete Reinforcement Usage

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products