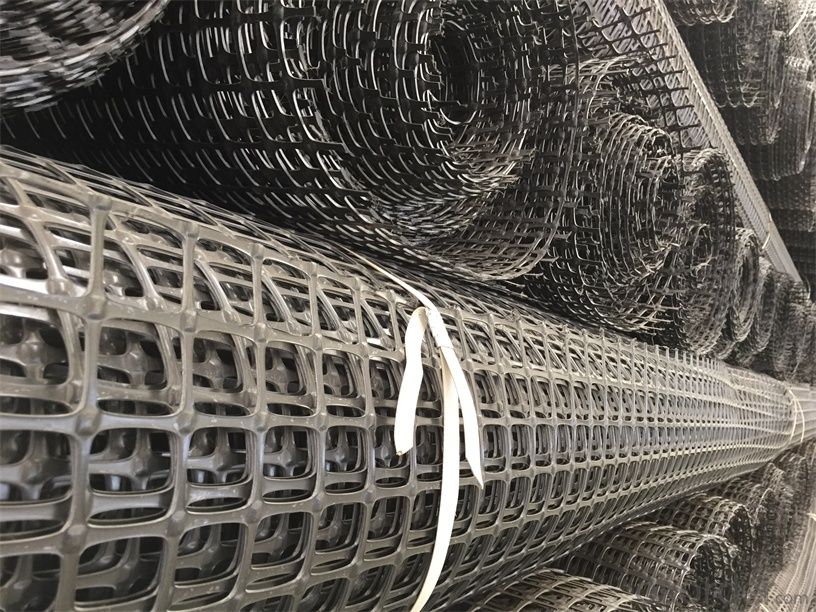

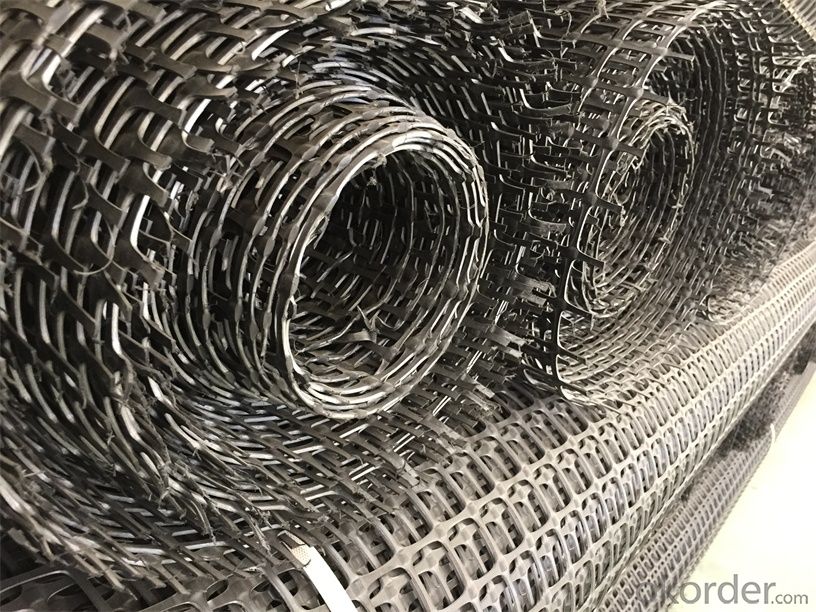

PP Biaxial Plastic Geogrids with Low Tensile Strength

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Introduction:

Fiberglass geogrid is a kind of planar mesh material using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt. It is warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant. Moreover, the composite property of coating with asphalt makes full protection of the fiberglass matrix and greatly improves its wear and shear resistance. All the advantageous functions make the product have a good performance in pavement strengthening, track cracking and solving difficulties of strengthening the bituminous pavement.

Fiberglass Geogrid Features:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications | PET20-20 | PET30-30 | PET40-40 | PET50-50 | PET80-80 | PET100-100 | PET120-120 |

Elongation(%) | 10%~15% | ||||||

Vert Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Horiz Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Grid(mm) | 12.5×12.5 20×20 24.5×24.5 | ||||||

Width(m) | 1—6 | ||||||

Fiberglass Geogrid Application:

1. Road surface asphalt overlay construction engineering; Asphalt layers

reinforcement.

2. Converting old cement concrete road into composite road; Restraining

reflection cracking caused by block shrinkage.

3. Road extension; Preventing and controlling the cracking caused by new

and old combination and uneven settlement.

4. Treatment of the conjunction between tunnel and bridge or foundation.

Packaging & Shipping:

FAQ:

1. How to order your geogrid ?

a) Tensile strength in warp & weft direction

b) Grid size

c) Roll Width and length

d) Quantity

2. What is the Payment term?

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

Welcome to send your inquiry to us, and if you have any question, we can also help you.

- Q:What is the meaning of 80 in geogrid TGSG80

- A model can be viewed as a double grid

- Q:What are the different installation techniques for geogrids?

- There are several installation techniques for geogrids, including mechanical connection, soil confinement, and anchorages. Mechanical connection involves attaching the geogrid to the soil or other structures using methods like staples, nails, or screws. Soil confinement refers to placing the geogrid within the soil mass to enhance its stability and prevent lateral movement. Anchorages are used to secure the geogrid by embedding it into a stable structure or using specialized anchoring devices.

- Q:How do geogrids improve the performance of geocell-reinforced slopes for erosion control?

- Geogrids improve the performance of geocell-reinforced slopes for erosion control by providing additional strength and stability. They help distribute the load evenly across the slope, preventing soil movement and reducing erosion. Additionally, geogrids increase the frictional resistance between soil layers, enhancing the overall slope stability and preventing soil slippage.

- Q:Are geogrids cost-effective?

- Yes, geogrids can be considered cost-effective. Geogrids help to improve the stability and performance of soil structures, reducing the need for excessive amounts of expensive construction materials. They also have a longer lifespan compared to traditional methods, resulting in lower maintenance and replacement costs over time. Additionally, geogrids can enhance project efficiency by reducing construction time and labor costs.

- Q:Are geogrids easy to install?

- Yes, geogrids are relatively easy to install. They can be installed using simple tools and equipment, and the process generally involves unrolling the geogrid, securing it in place, and covering it with soil or aggregate material. However, the ease of installation can vary depending on the specific project and site conditions.

- Q:Are geogrids resistant to alkali degradation?

- Yes, geogrids are generally resistant to alkali degradation. They are designed to withstand harsh environmental conditions, including exposure to alkaline substances, without significant degradation or loss of strength.

- Q:Can geogrids be used in reinforcement of stormwater management systems?

- Yes, geogrids can be used in the reinforcement of stormwater management systems. Geogrids provide added structural stability and strength to the soil, helping to prevent erosion and maintain the integrity of the stormwater management infrastructure. They are often used in the construction of retaining walls, embankments, and other drainage structures to enhance their resilience and long-term performance.

- Q:Which is the high price of steel plastic geogrid and fiberglass geogrid

- Universal steel grating high prices

- Q:What are the factors to consider in selecting a geogrid for a specific application?

- When selecting a geogrid for a specific application, several factors need to be considered. These factors include the required strength and durability of the geogrid, the type and condition of the soil being reinforced, the anticipated load or traffic on the geogrid, the climate and environmental conditions of the project site, and the cost-effectiveness of the geogrid. Additionally, factors such as installation requirements, compatibility with other materials, and the availability of the geogrid in the required dimensions and specifications should also be taken into account.

- Q:What are the testing methods for geogrids?

- Some commonly used testing methods for geogrids include tensile strength testing, creep testing, puncture resistance testing, and pullout testing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP Biaxial Plastic Geogrids with Low Tensile Strength

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords