Power/Push Button Switch

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Pieces pc

- Supply Capability:

- 8000000 Pieces per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Power Switch,push switch

push button switch

ventilator power switch

for for range hood;Smoke Extractor;kitchen

we can provide all kind of Power switch ,Pbs Push Button Switch

for range hood;Smoke Extractor;kitchen ventilator

Specification

Approved | CE,VDE,ROHS |

Verified | EPS-00126 |

RatedLoad | 6(2)A 250VAC |

Electric Resistance | 10.000 Cycles |

Environmental Temperature | -2585 |

Contact Resistance | 50m |

Insulation Resistance | 100M |

Withstand Voltage | AC1500V(50/60HZ)/1min |

Operating Force | As user requirement |

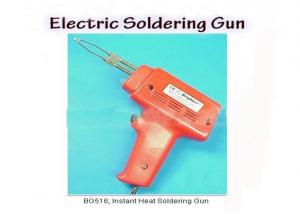

- Q:Electric iron, etc. is not inductive load?

- Upstairs, the answer is, in fact, is an impedance, high resistance ah, ha ha!

- Q:My electric iron is Aetna letter 936, the handle is 2 lines of heating core, but I bought a four wire heating core, how to modify it?

- Use it. It's not bad. The two lines are temperature control lines

- Q:How much W is the best to use for welding circuit boards? How much is it?

- Solder integrated circuit is best to use 20W, elephant resistor, capacitor class, use 30W. The integrated circuit will be damaged because of long soldering time and high temperature. Generally better electric iron on the 20 yuan.

- Q:Such as blade scraping, although to tin, but in a few hours with not occupied, and find solutions

- The electric iron does not solder tin because the iron head is heated for a long time and is exposed to oxidation in air. The solution is not in the case of heating by sanding, the exposed metal surface color fresh (scraping blade can), and then power, gradually try to melt the rosin (not paste), and touch the solder wire, with increasing temperature, make the soldering iron head plated a layer of tin (from the air), after the iron head will not be burned. Should pay attention to regular maintenance, after use, while hot with dry cotton cloth, wipe the iron head, leaving no debris, at the same time pay attention to the head always has a layer of solder

- Q:An electric iron marked "220v45w", how much heat is produced per minute at rated voltage?

- According to the heat formula, it should be correct.

- Q:The soldering iron rack has several advantages to the electric iron

- There is to help the iron without soldering iron heat, the head did not love hot oxidation, constant temperature iron is mainly to let the iron has a safe place

- Q:The electric iron should heat the pad. Do the solder wire melt on the pad or solder the solder on the soldering iron to the pad?

- Welding seems simple, and actually it is also a sophisticated technology. There is no standard procedure for specific welding operations, because the welding processes are different between different workpieces or under different conditions. The first step is to clean the iron head, thoroughly clean the iron head, and evenly coat the tin after heating. This step does not seem to matter, but it is an important foundation for the next step of welding. When welding, choose high quality solder, the quality of solder is too bad, not only affect the welding efficiency and quality, but also damage the weldment. High quality solder, solder joints have bright, poor quality solder, solder after welding white without light. When welding in most cases will tip top gently in the welding position, you say the pads or solder joints, wait after the heating wire to the solder melting, soldering tin mainly observe the degree of saturation in the melting process, the shape of satisfaction do now. Welding workpiece larger, there is no high-power iron, but also can use external heating method, welding non heat resistant workpiece, to be steady, accurate, fast, to advance welding tin for welding. The main flux, strong acid type zinc chloride, used for welding thick pieces of copper and tin. Medium acid solder paste for soldering smaller components. The above two soldering fluxes shall not be used for welding electrical wiring. Welding electrical wiring is commonly used weak acid rosin, rosin easy to evaporate, welding temperature should not be too high, welding lead wire remember to advance tin, so that more easily welding.

- Q:How do I remove the whole part from the circuit board? How about the electric iron?

- Don't bother / want to save money, just like me. Find some copper wire. Put the copper wire on the soldered joint of the component you want to take off. Use electric iron to heat itThe solder will melt all over the copper wire so that it can be removed!

- Q:Computer repair shop electric irons, head bent and pointed, very good, how can not see where the iron head to buy it?

- Under normal circumstances, they are bent, but there are also bending of the sale, Taobao on the search will know

- Q:I'm 40W thermoelectric iron, although can be defended, but not quite good-looking! What should the good welded USB interface and so on PCB!

- I am a solder manufacturer 0755-28105781, I QQ463641410 to use a little bit of tin wire, containing tin bright, at least to reach more than 50%. The higher the brightness of tin, the lower its melting point, the lower the content of tin, the higher the relative melting point, the effect of welding is not ideal, there will be false welding, tin is relatively slow, brightness, no amount of light.

Our company is a professional manufacturer and exporter of a wide range of electronic products.We are able to promise prompt delivery and favorable prices to our customers. OEM/ODM orders and your special requests are welcomed. Samples are available upon requests. We sincerely welcome domestic and foreign friends to negotiate trade and cooperation. Please contact us now. Our principle is to make mutual benefits with long-term cooperation. In order to satisfy customers' requirements, we will make great efforts to develop new products and improve our service. We hope to cooperate with all friends from all over the world.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu, China |

| Year Established | 2004 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Northern Europe Southern Europe South Asia |

| Company Certifications | CE |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Power/Push Button Switch

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Pieces pc

- Supply Capability:

- 8000000 Pieces per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords