Portland® N-TGD belt bucket elevator for tower compound fertilizer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 99 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The special elevator of tower compound fertilizer

The special elevator of tower compound fertilizer has formed a complete manufacturing standard, has established technical post for the industry .

According to professional research and development of new tape bucket product features in the chemical fertilizer industry,

The special materials characteristics of the tower granulation, such as strong corrosive, increasing additive, etc., we should improved machine improvement and process design, otherwise will lead to corrosion of steel member is faster,tape layup will be failure rapidly,the tail tension device will be failure,the incomplete discharge will cause too much of the feed back,the lock is serious,the tail will be taken ash and a series of problems, most similar equipments has these problems at present.

According to these problem, Our company’s elevator has been specific design.

1.The technical features as follows:

1.1 The steel cable belt for bucket elevator has independent intellectual property rights.

1.2 Belt joint device that has independent intellectual property rights of Bucket elevator is made special treated.

1.3 It has improved head device, matches with high wear-resisting vulcanization head wheel and cleaning device.

1.4 It has modified tail device, matches with rod cage and high precision tail wheel.

1.5 Improved strength tension mechanism of parallel four connecting rod and anti-corrosion treatment.

1.6 Shell and hopper are painted professional anti-corrosive paint.

1.7 Reduction scheme of positive pressure

1.8 The fixed technology of hopper has independent intellectual property rights.

1.9 The type of drive is suspension simply supported mechanism .

1.10 Reliable seal of head, and overall built-in tail dust bearing

1.11 The operation of control and protection device is perfect.

2 Technical Features

——Lifting height is up to 140m

——Conveying capacity is up to 1335 m3/h

——Instantaneous material temperature can reach 180°C

3 Model

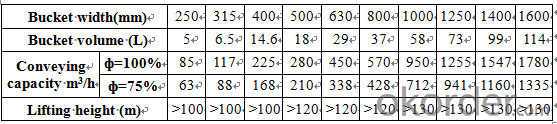

Table of conveying capacities table 1

Notes:a. The bucket volume is the volume when taking water, ф is the material filling ratio.

b. The maximum lifting height is the center distance C between the head shaft and the tail shaft.

- Q:The wear-resisting parts in the broken machine are mainly the direct contact with the material

- There is a need to contact, the crusher is a lot of model and the performance is different. For example: the jaw is broken, the hammer is broken, the fight is broken, the cone is broken... It is. Wear-resisting material is different also, also need according to the material hardness, strength of the material that is broken, the choice is ok. Materials: alloy white iron (high chromium cast iron), high manganese steel, alloy steel (high, medium, low carbon and alloy)... It is. It's best to find experienced manufacturers. Hope to adopt.

- Q:The development of material handling

- The material handling equipment manufacturing industry provides various kinds of modern transportation equipment for the national economy, major construction projects and national defense security. Basic formed a comprehensive product range, good technical system and large enterprise groups, become an independent industry, machinery industry in the service of national economy in all walks of life, including for the second and the third industry provides a huge number, a great variety of products, can independently or with foreign cooperation for national key project to provide large lifting transportation machinery and complete sets of equipment system, and have a certain amount of exports. In 2011, there were 1,580 enterprises in the manufacturing industry of material handling equipment in China (RMB 20 million), and more than 400 000 employees. The industry realized sales revenue of 4723.47 billion yuan, with an industrial output value of 4712.23 billion yuan, with a total profit of 34.50 billion yuan, with an average annual compound growth rate of over 20%. With the expanding of the scale of production, improve degree of automation, material handling equipment manufacturing industry is more and more widely used in the process of modern production, function more and more big.

- Q:The function of material handling

- Material handling USES all kinds of power and transport machinery to keep the material, such as count, punctually, safely, economically, and to the designated place. It is closely related to the choice of site selection and professional cooperation in the outside material handling machinery factory.

- Q:Why should we emphasize unitization and standardization in material handling

- Reducing the degree of climate impact, ensuring normal work, accelerating the flow of goods and improving efficiency. 1) logistics base module The logistics base modulus is the minimum size of the standard size of the logistics system. In basic module size was determined, the size of the various specific standards, should be based on basic module size, select the integer times to the prescribed standards for size, foundation modulus size is determined, just a standard size in multiple choice, it can be used as a standard of other size.

- Q:There are three things to do when the material is stacked up and down

- Fire prevention, waterproof, and do not exceed the limit.I hope my answer will help you.

- Q:The principle of material handling

- The principle of the effectiveness of the handling operation: the cost of carrying the unit to determine the performance of the transport. Safety principle: provide proper means and equipment to enhance handling safety.

- Q:What is the carrying equipment of the container cargo

- The dragon door crane, the container head crane, the empty box can use the forklift truck, the car crane can be very difficult to lift when the zero time

- Q:The beneficial effect of material handling machinery

- Material handling machinery is serving the production, its design and type selection should be subject to the needs of the production process, new material handling machinery but also often leads to the change and improvement of the manufacturing process. For example, the emergence of bucket wheel stacker reclaimer, formed the bucket wheel stacker reclaimer for heart, belt conveyor for blood vessels, the electronic computer is the nerve center of automation of large bulk material handling system, which changes the ports, mines and the layout of the power plant and so on of the bulk yard; It can simplify the structure of the factory and reduce the cost of construction.

- Q:What are the requirements for the science of loading and unloading

- Reduce the load ratio of the mobile carrying equipment. To optimize the utilization rate of transportation equipment and manpower. Plan all the equipment to be maintained and maintained regularly. When there are more efficient means of handling and equipment, it should replace obsolete methods and equipment.

- Q:What is the material handling and handling equipment?

- Lifting equipment Small lifting equipment | gantry crane | | bridge cantilever crane | 2 vertical mechanical unit transportation equipment | gravity conveyor power conveyor parts | | | other comprehensive transportation system

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Portland® N-TGD belt bucket elevator for tower compound fertilizer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 99 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords