Portable Edge Bander Edge Banding Machines of Different Kinds

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Edge Banding Machines-Panel Saw Description

A panel saw is any type of sawing machine with a sliding table that cuts sheets into sized parts.

A sliding panel saw was invented by Wilhelm Altendorf in 1906 in Germany. Its invention set a new standard in woodworking, with dramatic differences from traditional machines. Up to that time, a conventional table saw had no mechanism for edging. Meaning that for the first and second longitudinal cut on untreated massive wood, the lumber always had to be fed manually through the saw blade. The new system accomplished the task more elegantly by allowing the work piece to be fed through the saw blade while lying on a sliding table. Thus cutting becomes faster, accurate and effortless.

2.Main Features of Edge Banding Machines-Panel Saw

Panel saws are used by cabinet shops to easily cut panels, profiles, solid-wood, MDF, laminates, plastic sheets and sheets into sizes or cabinet components. They are also used by sign shops to cut sheets of aluminum, plastic and wood for their sign blanks. Some higher end panel saws feature computer controls that move the blade and fence systems to preset values. Other lower end machines offer simplicity and ease of use, including full scale hobbyist level panel saws at a mere fraction of the cost. While the entry level machines are designed for light duty usage, they offer home DIYers a cheap alternative for infrequent cutting when accuracy and clean cuts are not required.

Panel saws can have one main saw blade, or a scoring along with a main saw blade. Scoring is used to create a groove, especially in double side laminate before the main saw rips the piece apart, to avoid chipping. The scoring saw rotates in an opposite direction, as the main saw to avoid chipping.

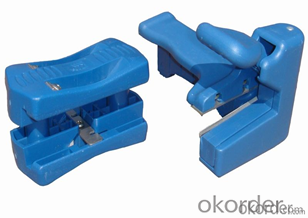

3.Edge Banding Machines-Panel Saw Images

4.Edge Banding Machine-Panel Saw Specifications

Maximum cutting length2800mm2800mm

Maximum cutting thickness80mm80mm

Main Blade sizeΦ305×Φ30mmΦ305×Φ30mm

Slot Blade sizeΦ120×Φ22mmΦ120×Φ22mm

Main saw shaft speed4000/5000rpm4000/5000rpm

Slot saw shaft speed9000r/min9000r/min

Main saw motor power5.5kw4kw

Slot saw motor power1.1kw1.1kw

Total power6.6kw5.1kw

Suction mouthΦ100×1Φ100×1

Weight800kg770kg

Box set dimensions3400×1150×1100mm3400×1100×1100mm

5.FAQ of Edge Banding Machines-Panel Saw

1) What can we do for you?

.We can ensure the quality of the Edge Banding Machines-Panel Saw and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. If interested in this kind of formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q:Cross stitch edge ornaments how?

- The embroidered figure leaves two or three, the rest are cut off, and then put two pieces of the same can repair the suture, suture when in fact it is best not to use the fishing line, because it is not just the line Yuntie, with cotton, nice and strong, the color edge of cotton to choose if you stitch, is cluttered with black or white, you try, definitely better than the suture line.

- Q:Today I bought a set of cabinets, in order to forestry Jilin Lushuihe EO health specially selected the particleboard, particleboard on both sides but when construction workers in the marble table below the pad without edge, now feel that the taste is quite big, and the estimate is. Consult an expert, how do you do the edge banding for the shaving board? With solid wood edge strip or PVC or aluminum foil? With universal glue, you can reduce formaldehyde emissions to achieve the effect? Thank you very much!

- I think PVC is better, only less adhesive in particleboard sizing two times to put in prison

- Q:With full automatic tracking edge sealing machine, that is, curves and straight lines can be "edge banding" mean?

- No, the copy tracking is to fix the shape of the head and tail of the board, such as the duck's tongue

- Q:How about the semi-automatic edging machine and the three row drill?,

- The workers are very expensive, my friend asked me to buy, is a manufacturer of Qingdao, named Qingdao Haoda edge machine woodworking machinery, cutting saw and drill, I am still very good quality with

- Q:How to solve the problem of sealing the package door?

- Have the door door

- Q:Edge sealing machine, furniture, or paste the edge of furniture, good, what is the difference?

- You're talking about the production process, and the result is one thing.

- Q:Is it true that Lushuihe doesn't do edge banding?

- What's the problem? My family is Lushuihe. What border banding?

- Q:My home closet is the use of paint free plate, at that time did not understand, the master fooled me to install the aluminum alloy edge banding. Ugly to death. Want to take it apart?. Please help God. Thanks again!

- Best picture attached

- Q:What is the difference between cutting edge plate and its own processing?

- Machine edge is certainly much than manual edge banding machine edge is strong, the first special hot melt adhesive, sealing with adhesive only

- Q:Who can tell me the name of this kind of edge sealing wood paper? Anyway, not called edge banding, Taobao only the kind of 1MM thick PVC, right. That glue can not stick, it will rise, this thin is also wood grain, glue can be affixed to the board, can not afford to alice. I don't know what it's called. I can't find it on Taobao. There's only solid wood on Taobao. I'll buy this thin one. Who can tell me its name? Where can I buy it?

- Veneer Edge banding. There are many treasures in Amoy 1. Hope to help you, thank you, please adopt

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Portable Edge Bander Edge Banding Machines of Different Kinds

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords