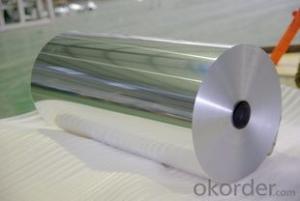

Popular Tropical Blister Foil of high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tropical aluminum packaging is not cold forming of aluminum substitution, packaging solutions different but for moisture requirements of different medicines and the display effects and provide. The main difference between tropical aluminum and cold forming aluminum function lies in the heat sealing effect depends on the damp proof effect of edge and PVC blister, in the sealing process stability, heat sealing temperature, heat sealing mold surface smoothness, uniformity pressure affect the heat sealing effect, in this case the coating layer, tropical aluminum itself more play a decisive role.

Hui made coating process heat sealing glue packaging quality and stable to ensure the effect of adhesive coating, let the heat sealing has no hidden danger.

Like the cold forming of aluminum, we also provide a tropical aluminum color and printing effect and the thickness of the different structure, give you more choices.

Structures

OPA/AL/VC, ordinary thickness 0.090--0.10mm, 200~230g per square meter.

·Characters

As the shield of PVC hard chips for blister packaging , it doesn't directly contact foods or drugs, suitable for high-density drugs;

high barrier performance against moisture, oxygen, light and UV rays;

Used as special packaging materials for the drugs under the extreme ( high or low Temperature) environment;

Fine printing on the flat appearance for advertising.

·Main applications

It can be used as the high-density packing materials for troches, pills, powers, and capsules gels and etc. eg: the typical application is the packing for the healthy foods of Golden Partner.

- Q:How to distinguish between PET gold card paper and foil gold paper peritoneum what is the difference?.

- 3. combustion test:The PET gold paper is completely burnt to ashes. The foil gold paper is burned to ashes and the metal foil is left

- Q:Aluminum foil waterproof material, how much does it cost for a square?

- The material is different, the price is also different. You first have to figure out what waterproof material can determine the price of this material.

- Q:How many degrees of aluminum foil can burn?

- You can use ordinary lighter lit, but not spontaneous combustion, left his flame out

- Q:What is aluminum foil?Direct rolling with metallic aluminium

- Characteristic:(1) the surface of aluminum foil is clean and sanitary, and no bacteria or microorganisms can grow on its surface.(2) aluminum foil is a non-toxic packaging material, it can be in direct contact with food, and there is no harm to human health.(3) aluminum foil is an odorless and odorless packing material, which will not cause any peculiar smell of packaged food.(4) if the foil itself is not volatile, the food itself and the packaged food will never dry or contract.(5) there is no grease penetration in aluminum foil, whether at high temperature or at low temperature.

- Q:The action of perforating aluminium foil and non perforating aluminium foil

- There is no such thing as "cold" in the world. What you call "cold transmission"?",

- Q:What is a composite aluminum foil molded poly vinyl foam board, and what is a composite aluminum foil extrusion poly vinyl vinyl insulation board, the two how to distinguish?Please try to be more specific

- 5, flame retardant properties of EPSXPS can reach B1 B26, the price of EPS is lower than XPSConclusion, if used in air conditioning, air duct and so on, XPS is superior in performance analysis,

- Q:Why can copper foil and aluminum foil shield electromagnetic signals?

- In addition because the copper or aluminum oxidation caused by the contact resistance increases, the long-term use of suggestions for tinned copper foil, shielding effectiveness after 2 years will not fall too much. I have a new measurement of shielding effectiveness of copper foil and tinned copper foil at the beginning are basically the same, 114dB (copper 1GHZ) and 112dB (tinned copper 1GHZ). The shielding effectiveness of one year after the 84dB (copper 1GHZ) and 110dB (tinned copper 1GHZ). The effect is really bad.

- Q:The difference between aluminum foil and aluminum foilThe performance of these two products, hygiene, price difference

- And now the rise of the price is aluminum foil, foil cheap, most of the packaging is aluminum foil.How many a little tin containing lead, from food hygiene, than foil. Aluminum foil

- Q:Where are the aluminum foil lunch boxes used?

- They are aluminium foil, some restaurants, takeout packages, barbecue boxes, and some baking shops

- Q:What's the use of aluminum foil?

- Soft package aluminum foilIs the use of flexible packaging bag type container made of soft composite packaging materials, soft packaging has greatly improved the level of mechanization and automation of the food and beverage industry, accelerate the modernization and socialization of people's diet life. In developed countries, soft packaging has become one of the main packaging forms of food and beverages, and has replaced cans and bottles in a certain range. In recent years, China's packaging market development is also very fast, has introduced a 10 aluminum foil production line, according to the different purposes of the soft packing dry composite, composite, hot melt extrusion composite technology etc.. Flexible packaging not only has the function of moisture-proof and preservation, but also can print various patterns and characters. It is the ideal material for modern commercial packaging. With the improvement of people's living standard, there is still a lot of room for the development of flexible packaging aluminum foil.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Popular Tropical Blister Foil of high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords