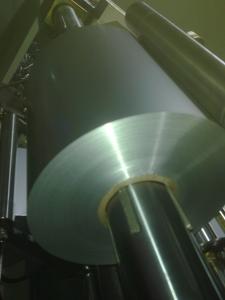

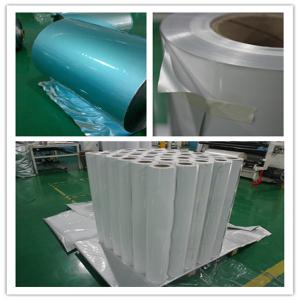

Popular Cold Forming Foil of good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cold forming of aluminum is the barrier of the best composite packaging materials, with the high-end appearance and excellent moisture resistance. However, as the cold punching molding material, in the stamping process of packing, blister bubble breaking and stratified phenomenon also exists, so that the production efficiency is low, serious waste of materials, and more importantly, bring hidden trouble to the drug quality.

Packaging equipment performance, die size will have influence on the forming effect, we have been thinking, how to let the cold forming of aluminum is no longer critical packaging machine and mold, with 100 percent adaptability, prevent because the packaging equipment and mold depending on the molding effect fluctuation.

Increase the tensile properties of cold aluminium, enhanced tear strength, broken bubble rate reduced to a minimum, destroy the stratification, we diligently goal, you have a inertia packaging has a set of effective methods to ensure the quality, which can smooth operator in any production conditions, put an end to your any menace from the "rear"!

At the same time, we provide different thickness structure materials to meet different requirements of bubble type, give you more choices, to solve the problem of more.

In addition, we provide the printing, color type cold aluminum, for you to create more value.

- Q:How do you microwave the chicken wings with aluminum foil?

- When microwave oven uses microwave gear, it is not allowed to have any metal substance in the container. Otherwise, a work will start the internal ignition and damage the microwave head

- Q:Can foil be used to shield electromagnetic interference? Please, great God!

- There is a certain effect, because it is a metal layer, of course, your package method also has a certain relationship

- Q:The aluminium foil is melted and glued to the electric ceramic stove. How can I get rid of it? A safe way of not hurting the stove

- Reheated and thawed again.If the area of the foil is slightly larger, you may consider dropping the cold water at the high temperature after heating. But do not control the amount of water dripping. Be careful not to spill the water onto the ceramic panel to damage the panel.

- Q:What is aluminum foil, please?

- A shielding film, with more in the electronics industry, to shield the disturbance effect, is the commonly used single blue aluminum foil, I know commonly useful in electronic line wrapping plays a role of anti-interference.

- Q:For the first time, the microwave oven roast chicken wings, no use of aluminum foil, baked chicken wings can also get in, but the microwave oven is oil, the roast, bought a foil, but do not know how to use, is wrapped in chicken wings or on the grill, how much time temperature? Does the foil burn when the temperature is high? The first 4 minutes with no bake aluminum foil side, a total of 8 minutes OK!! I don't know how to use aluminum foil this time Headache...

- Hold it evenly and refrigerate for two hours.After the removal of each wing is uniform with cornstarch.Put the microwave oven on the grill for twelve minutes and turn over halfway.

- Q:The difference between pure aluminium foil bags and aluminium plated bags

- Three, from the performance point of view, pure aluminum bags moistureproof, cooling effect better than aluminum bag, pure aluminum bag completely avoid light, aluminized bag is shading effect.Four, from the use, the pure aluminum bag is more suitable for vacuum pumping, such as food, meat and other products, while the aluminum plated bag suitable for tea, powder, electronic and other pieces.Five, the inside of the bag facing the light or sunlight, can see through the bag of light is plated aluminum foil, invisible is pure aluminum foil

- Q:What is the light aluminum foil?

- Natural rubber can be regarded as an unmodified epoxy resin. It can be used as cover and foil coating

- Q:How to improve the cleaning effect of aluminum foil

- Put the thermos bag flat and wash it slowly with water.Thermal insulation bag, ice bag, ice bag, also called passive refrigerator, is a kind of high insulation and constant temperature effect package (it has the function of cool in summer and warm in winter)

- Q:What is an aluminum foil woven bag?

- (3) high temperature (121 DEG C), low temperature (-50 DEG C), good oil resistance and good incense retention.(4) non-toxic, tasteless, in line with food, drug packaging hygiene standards.(5) good heat sealing property, softness and high barrier property.

- Q:Can foil foil be put on and off?

- It can be assured that shading will not fall, light, pollution free and cheap. For high grade cigarettes, sweets and other food moistureproof and decorative packaging.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Popular Cold Forming Foil of good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords