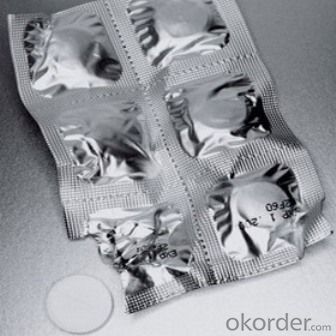

Popular AL/PE Laminated Blister Foil for Medical Package

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 700 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

AL/PE Laminated strip pack

1.Introduction

AL/PE (Laminated strip pack) manufactured in well-equipped R 100,000 filter class GMP workshop, the quality of products under controlled by the ISO9001 quality management system, and the working environment through ISO 14000 certification. The face and inverse of the packing for drug products are also covered by AL/PE compound film, and the two surface also can include the aluminum foil resisting vapor, air-proof and lights, the PE of the inner surface can keep good heat insulation to make it own excellent air tightness, and then extend the preservative period of its contents and have some extensiveness and with standing pressure, and the most obvious trait is the performance of heat tightness at low temperature, especially applied to those drugs which can't be packed at high temperature

2.Structures

AL/PE

3.Characters

Good barrier properties to resist vapor, all kinds of gases and lights;

PE of the inner surface can keep good heat insulation to make it own excellent air tightness, and then extend the preservative period of its contents;

the performance of heat tightness at low temperature, especially applied to those drugs which can't be packed at high temperature.

4.Main applications

It can be applied to the low-density tablets, capsules, suppositories, particles and etc.

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 40 working days can be served.

- Q:I have naturally ash blonde hair but I've highlighted it for the past 2 yearsMy roots are starting to grow out again and I was looking at the Coloure Experte kit from Loreal that is 2 steps, you do a base color first, dry it and then do highlightsThe only problem is I'm scared the highlighting cream might drip onto other parts of my hair so my question is: Can I apply the highlighting cream to a strand of hair and then cover it with aluminum foil while it processes to keep it from dripping on the rest of my hair, or will the hurt the whole highlighting process?Thanks!

- Some hair products are not to be used with metals so I can only suggest that if you want to seperate the hair then I would use clingfilm instead of foilHope this helps.s

- Q:What are some tasty summer treats children between 5-12 could enjoy helping with?

- Easy, fun, and tasty treats: Frozen Bananas - Peel bananas and put a popsicle stick insideDip in your choice of melted chocolate and put any topping onto it(Like nuts, sprinkles, etc).Put into freezer until frozen, then eatKoolaid popsicles - Pour koolaid into ice holders, and put a popsicle stick (tooth picks work too) in each oneFreeze until hardS'mores - Put 2 hersheys chocolate squares and a marshmallow in between 2 graham cracker squares and microwave, or use a stoveChocolate Pudding Pops- Ingredients 1 small package of instant chocolate pudding (3.4 ounces or 96 g) 2 cups milk 1/2 cup sugar Instructions With a wire whisk, blend together 1 package of instant chocolate pudding, 2 cups milk, 1/2 cup cream, and 1/2 cup sugarPour the mixture into popsicle moldsOr, pour it into small plastic cups, cover each with aluminum foil, and insert a craft stick through the foilFreeze and eatFrozen Flower Pops: Ingredients Fresh pineapple Watermelon Green apple Instructions Make the petals by cutting notches in a 1/2-inch-thick fresh pineapple ring, then place a watermelon ball in the centerFor a leaf, skewer a slice of green apple, then push the skewer stem into the pineapplePlace the flower on a wax-paper-covered tray, cover with plastic wrap, and freeze for about 1 hour.

- Q:I am performing a science fair experiment, and I only need a portion of the solar panelWhat can i use to block incoming light?

- it up with some cornmeal, greens and RC cola

- Q:Im trying to help my friend out with his costume, hes gonna be freddy krueger for halloween.I know there freddy masks they sell at stores, but we want to try and do it ourselvesI cant imagine its that hard, and Im a pretty crafty person but havent ever tried anything past face-painting and paper-mache in the realm of masks.Some ideas i have are working with liquid latex(which i read about in a book)I also heard of rigid collodion, but im not sure thats what i needMy biggest issue is in how im going to texturize the bumps/scars on his face, i figure i can just paint the muscle on the flat surfaces that remainAny ideas would help A LOT, thanks

- I don't know how much exact detail your after but to make a haggard bad complexion like his you can make a mold of your friends face with a few layer of aluminum foilRest it on some scrunched up paper as a supportCover with strips of paper mach'e Use pureed paper pulp to get the desired shape and bulk you are afterBeing crafty you probably know what I'm talking about without going in to too much detailJust use three different shades of skin color paint, dark being the main, medbeing the sides of his ,lumps bits, light being on the top of his crators scars etc.

- Q:I saw on Kathy lee and Hoda show how to soak silver and it comes out like new with no rubbingCan you help me with that

- Stainless steel is inert and will not react with the waterThis means that the kettle stays in like new condition for longer and does not contaminate the water for your tea or coffee.

- Q:recipe:1 pound Powdered Sugar1/2 cup Cocoa1/4 cup Milk8 tablespoons Margarine1/2 teaspoon VanillaMix sugar and cocoa together in large bowl, pour milk in sugar mixture and set margarine on topMicrowave 2.5 minutes on highMix well and add vanillaPour on aluminum foil covered plate, put in fridge for 30 minutesFor an ice cream topping, add more milk when cooking.all i have is granulated sugar, and no processor/blenderdo you have a recipe similar to this oneor an idea of what i can do?

- You can probably find an empty propane tank for freeEven full of propane, it's like three bucksAnd they have two threaded holes, one's a schrader valve like a car tire.

- Q:how would you go about making your own cooler?

- paint, i like the way it smells

- Q:How long to heat a ham?

- If you choose to use a blanket with your baby, to help avoid SIDS put baby with feet at the foot of the cribTuck a thin blanket around the crib mattress, reaching only as far as the baby's chestThis way she can't scoot down and under the blanketMy son was born in July and sleeps with a blanket every night.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Popular AL/PE Laminated Blister Foil for Medical Package

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 700 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords