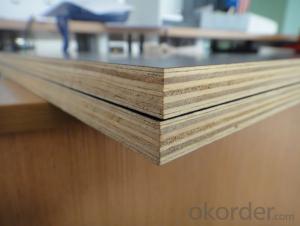

Poplar Core Brown Film Melamine Glue Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

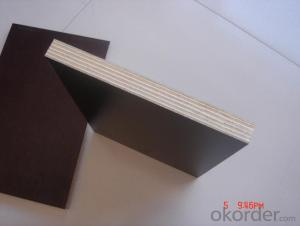

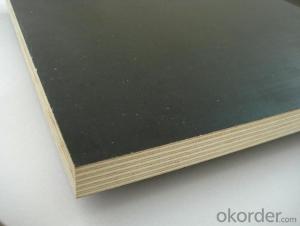

Item Name:Film Faced Plywood/Shuttering Plywood

Size:1220x1440mm,1250x2500mm

Thickness:9mm,12mm,15mm,18mm,20mm,25mm,other thickness as requested

Description

Main material | Poplar, hardwood, combic of poplar and harwood |

certification | CE ISO9001 |

Brand name | CMAX |

size | 2440mm*1220mm, |

thickness | 12mm 15mm 18mm, 21mm |

Face&back | Black film |

core | Poplar or hardwood |

gule | Phenolic/WBP /melamine/MR |

moisture | <=10% |

Joint way | Overlap joint, end joint |

format | two times hotpress/one time hotpress |

color | Black |

Thickness tolerance | Minus or plus 0.3-0.5mm |

certification | ISO9001 CE |

Application | Construction concrete formwork |

payment | L/C at sight or T/T |

Packing | 1)Inside pallet is wrapped with a 0.20mm plastic bag 2) Outer packing: Pallets are covered with 3mm package plywood and then steel tapes for strengthening |

Shipment | Within 10 days after receiving deposit or L/C |

Supply ability | 6000m3 per month |

MOQ | 1*40 HQ container |

loading Port | Qingdao port or Lianyungang port |

quantity | 18 pallets in 40HQ container |

Features

1) Good Raw Materials and High quality

2) More repeated using times

3) Good packing and fast shipment

4) Delivery the right products according to different level of requirement

5) High performance/price ratio

FAQ

1.What's your company property ?

More than 10 factories to meet your various needs.

2.Free samples ?

Samples are free. As for the cost of courier , we will give back to you in the payment of the trial order .

3.What's your delivery time ?

The goods will be deliveried wthin 15 days after recepit of the deposit .

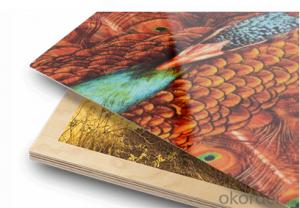

Products Photos

- Q:What are the allowable quantity differences in printed packaging materials?

- The ink thickness, three-dimensional sense of common offset and letterpress 5 microns to about 12 microns in gravure printing, flexo printing ink layer (aniline) is 10 microns thick, and the wire net printing ink thickness than the ink layer thickness is generally up to about 30 microns. Thick screen printing special printed circuit board, ink film thickness of up to 1000 microns. Foam ink printing Braille, foaming layer thickness of up to 300 microns. Screen printing ink layer thickness, printing texture rich, three-dimensional feeling strong, this is other printing methods can not match. Screen printing can not only print in monochrome, but also capture and screen color printing.

- Q:What are the materials used in screen printing?

- Specifically, screen printing is mainly used in the following aspects: the art printing paper printing: advertising, jhenuk, calendar, lantern paper etc..Trademarks, printing, transfer printing, packaging, printing, building materials printing - wallpaper, etc. plastic printing plastic film - ethylene toys, bags, plastic bags and so on.Plastic plate -- false metal composite material and various labelsManufacturing parts - instruments.Wooden products printingHandicrafts - lacquerware, wooden arts and crafts, toys.Processing semi manufactured goods - sporting goods, boards, ceilings, road signs, signboards, fake metal wrenches, billboards, etc..Printing of metal productsMetal barrel, metal ware, metal product.Printing of glass and ceramic productsGlass -- mirrors, glass plates, cups, bottles, etc.Ceramic ware, arts and crafts.The label text plate, dial, shaped articles.The printed circuit boardPrinted circuit board, board for civil or industrial use, thick film integrated circuit board.The printing and dyeing cloth, printing and dyeing, flags, towels, handkerchiefs, shirts, vests, knitted fabrics etc.. 'Other printing - pockets, shoes, numbers, cloth, bags, backpacks, bags, schoolbags, etc..

- Q:What's the printing process for PC material? Is the print content on PC or other surfaces?

- Roll material, screen printing or rotary printing (relatively few, only for thickness below 0.125MM), printing the same as above.

- Q:Carton printing process and materials

- Direct offset corrugated carton process, corrugated box direct offset printing technology has been relatively mature in foreign countries, it is corrugated cardboard directly in a special offset printing press. The utility model is suitable for processing thin corrugated boxes.This process can ensure the formability of the carton, and can complete the fine printing paper printing machine, but the price is more expensive, and the requirement of our country standard is not suitable, not suitable for carton industry to adopt in the near future, but in the next few years, the process may become China's high-end a new direction for the development of carton printing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Poplar Core Brown Film Melamine Glue Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords