Polyvinyl Chloride (PVC) Roofing Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

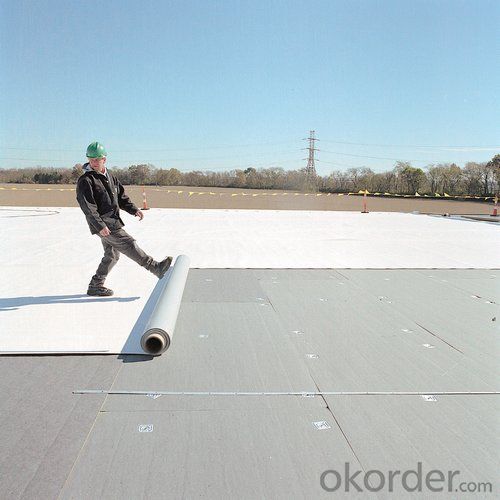

Polyvinyl Chloride (PVC) waterproof membrane is a new polymer waterproof membrane which is made from polyvinyl chloride resin, and mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Specification

Length | 20m/roll or customized |

Width | 2.05m |

Thickness | 1.2mm; 1.5mm; 2.0mm |

Type | Homogeneous, Reinforced, Fabric back |

If Exposed | Exposed and Non-exposed |

Color | White, Grey or customized |

Features and Benefits:

a) High Strength

b) Hot-air welded seams for long-term performance

c) Proven membrane performance

d) Excellent resistance to plasticizer extraction and migration performance.

Usage:

a) Roofing (covered & exposed roofs)/ Re- roofing

b) Tunnel Lining

c) Tanking of Underground structures

d) Lining of evaporation ponds & artificial lakes

e) Lining of drinking water tanks & swimming pools

f) Agricultural purposes & Lining of irrigation canals

RFQ

1. What is your MOQ?

--Our MOQ is 5000 m2

2. Can you provide sample?

--Yes, samples are in stock. we can offer free sample for you.

3. Do you offer OEM service?

--Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q:Can a waterproofing membrane be used for tunnels or subway systems?

- Yes, a waterproofing membrane can be used for tunnels or subway systems. Tunnels and subway systems are often subjected to water infiltration due to the surrounding soil conditions or groundwater levels. To prevent water from entering these underground structures, a waterproofing membrane is commonly applied. This membrane acts as a barrier, preventing water from seeping into the tunnels or subway systems. It is typically installed on the exterior surface of the tunnel walls and roof, creating a watertight seal. This helps to prevent corrosion, decay, and damage to the structural elements of the tunnels and ensures the safety and longevity of these underground infrastructures.

- Q:Can a waterproofing membrane be used for a retaining wall?

- Indeed, a retaining wall can benefit from the utilization of a waterproofing membrane. Typically employed to restrain soil or other substances, retaining walls frequently encounter moisture and water pressure. By employing a waterproofing membrane, one can establish an efficient barrier that thwarts the infiltration of water through the retaining wall, thus circumventing potential harm. This can effectively uphold the structural integrity of the wall and extend its lifespan. Nevertheless, it is crucial to select a waterproofing membrane that is suitable for the specific conditions and requisites of the retaining wall. To guarantee the effectiveness and durability of the waterproofing membrane, it is imperative to seek professional guidance and adhere to proper installation techniques.

- Q:Can a waterproofing membrane be used on precast galvanized surfaces?

- Precast galvanized surfaces can benefit from the use of a waterproofing membrane. This membrane serves as a safeguard against water infiltration and can be applied to various surfaces, including precast galvanized ones. By preventing water from seeping into the surface, the membrane safeguards the underlying structure from moisture damage. However, it is crucial to prepare the precast galvanized surface adequately before applying the membrane. This involves removing any loose or flaking galvanized coating to ensure proper adhesion of the membrane. Furthermore, it is recommended to consult the manufacturer or supplier of the waterproofing membrane to guarantee compatibility with galvanized surfaces and to follow their recommended application guidelines for optimal outcomes.

- Q:Can a waterproofing membrane be used in parking garages?

- Parking garages can benefit greatly from the use of a waterproofing membrane. Due to their exposure to various weather conditions and heavy vehicular traffic, these structures are susceptible to moisture infiltration and structural damage. Therefore, it is crucial to install a dependable waterproofing system to safeguard against water penetration and potential deterioration. A waterproofing membrane serves as an effective solution for parking garages by acting as a barrier against water and moisture. It is typically composed of durable materials such as modified bitumen, PVC, or EPDM, which are resistant to water intrusion. When applied to the concrete surface, the membrane forms a protective layer that prevents water from seeping through. By preventing moisture from penetrating the concrete, the waterproofing membrane not only defends the parking garage against water infiltration but also helps to prolong its lifespan. This, in turn, reduces the risk of corrosion, deterioration of reinforcing steel, and the formation of cracks. Ultimately, the structural integrity of the parking garage is maintained, saving on costly future repairs or replacements. Moreover, a waterproofing membrane can offer additional advantages, including resistance to chemicals, UV radiation, and abrasion. This makes it an ideal solution for parking garages that face harsh environmental conditions and heavy traffic. To summarize, the use of a waterproofing membrane is highly recommended for parking garages. It provides reliable protection against water infiltration, helps to maintain the structure's integrity, and extends its lifespan.

- Q:Does a waterproofing membrane require a primer before application?

- Yes, a waterproofing membrane typically requires a primer before application. A primer helps to enhance the adhesion of the membrane to the substrate and ensures a proper bond between the two. It also helps to seal the surface, preventing any moisture or contaminants from compromising the effectiveness of the waterproofing system. Using a primer before applying the waterproofing membrane is important for achieving a durable and long-lasting waterproofing solution.

- Q:Can a waterproofing membrane be used on aluminum surfaces?

- Yes, a waterproofing membrane can be used on aluminum surfaces. Waterproofing membranes are versatile and can be applied to various types of surfaces, including aluminum. These membranes are designed to provide a protective barrier against water and moisture, preventing leaks and water damage. Applying a waterproofing membrane on aluminum surfaces can help extend the lifespan of the material by protecting it from corrosion and rust caused by water exposure. However, it is important to ensure that the waterproofing membrane chosen is compatible with aluminum and suitable for the specific application to achieve optimal results.

- Q:Can a waterproofing membrane be used on precast glass surfaces?

- Indeed, precast glass surfaces can benefit from the utilization of a waterproofing membrane. It is common for precast glass surfaces to possess joints and seams that allow water to infiltrate. Applying a waterproofing membrane can effectively establish a protective barrier against water penetration. By doing so, the waterproofing membrane acts as a safeguard, preventing moisture from seeping into the joints and causing potential harm to the precast glass. It is crucial to select a waterproofing membrane specifically designed for glass surfaces and to adhere to the manufacturer's guidelines for proper application. Moreover, it is prudent to perform regular maintenance and inspections to ensure that the waterproofing membrane remains effective over time.

- Q:What is the difference between PET waterproofing membrane and BAC waterproofing membrane? What is the commonality? Is BAC a PET?

- PET refers to polyethylene terephthalate, PET film using polyester composite film as the surface material, coated with rubber asphalt adhesive material, with cement mortar paste or self-adhesive. Can be constructed on the wet base surface, the grass-roots requirements are low, with high bond strength, bonding effect is good, not channeling water and so on.

- Q:Can a waterproofing membrane be used for a restaurant kitchen floor?

- Yes, a waterproofing membrane can be used for a restaurant kitchen floor. It provides protection against moisture and helps prevent water damage to the underlying structure. Additionally, it can make cleaning and maintenance easier by creating a seamless, waterproof surface.

- Q:Can a waterproofing membrane improve energy efficiency?

- Yes, a waterproofing membrane can improve energy efficiency. A waterproofing membrane acts as a barrier against moisture intrusion, preventing water from seeping into the building envelope. By keeping the structure dry, it helps to prevent the growth of mold and mildew, which can contribute to poor indoor air quality and the deterioration of building materials. In addition to protecting against moisture, a waterproofing membrane can also provide insulation benefits. Many waterproofing membranes are designed to have a high thermal resistance, or R-value. This means that they can provide an extra layer of insulation to the building, reducing heat transfer through the walls or roof. By improving the building's thermal performance, a waterproofing membrane can help to reduce the load on heating and cooling systems, resulting in energy savings and improved energy efficiency. Furthermore, a waterproofing membrane can also help to reduce air leakage in a building. Air leakage can account for a significant amount of energy loss, as conditioned air escapes through gaps and cracks in the building envelope. By sealing off these areas, a waterproofing membrane can help to improve the building's air tightness, reducing energy loss and improving energy efficiency. Overall, a waterproofing membrane can play a crucial role in improving energy efficiency by preventing moisture intrusion, providing additional insulation, and reducing air leakage. Investing in a high-quality waterproofing system can lead to long-term energy savings, improved indoor comfort, and a more sustainable and efficient building.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polyvinyl Chloride (PVC) Roofing Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords