Polyurethane Waterproof Coating for Swimming Pool

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single Component Polyurethane Waterproof Coating Introduction

Single-component moisture-curing pure polyurethane waterproof coating is a kind of liquid polymer waterproof material,

suitable for dry and wet base surface construction, solidified into tough and elastic, non-toxic and tasteless waterproof

film after coating. It is a new type of environmental friendly waterproof material without solvent.

Single Component Polyurethane Waterproof Coating Application

•Building roof

•Concrete

•Wall

•Water Tank Structure

•Floor(kitchen floor, bathroom floor ect)

•Underground Tunnel

•Sewerage Structure

•Movement Joint

•Wet Area, Pipes, Sewer & etc.

Single Component Polyurethane Waterproof Coating Advantage

1.water based and solvent based

2.Solid content above 80%

3.Durable performance, UV resistant, ageing-resistant,resistant high and low temperature,antifatigue, withstand constant immersion in water

4.Good splicing performance

5.Operate conveniently, low viscosity

6.Can splicing with concrete and many kinds board stuff

7.Will not change color after used

8.Apply for Roof,Swimming Pool,Tank and more

Single Component Polyurethane Waterproof Coating Specifications

NO. | Items | Ⅰ | Ⅱ |

1 | Tensile Strength MPa≥ | 1.9 | 2.45 |

2 | Elongation at Break %≥ | 550 | 450 |

3 | Tearing Strength N/mm≥ | 12 | 14 |

4 | Bend at Low Temperature°C≤ | -40 | |

5 | Unpermeability0.3MPa 30min | Impermeable | |

6 | Solids Content%≥ | 80 | |

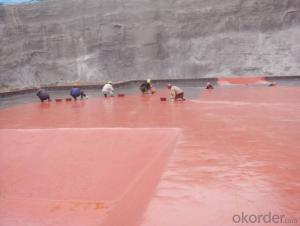

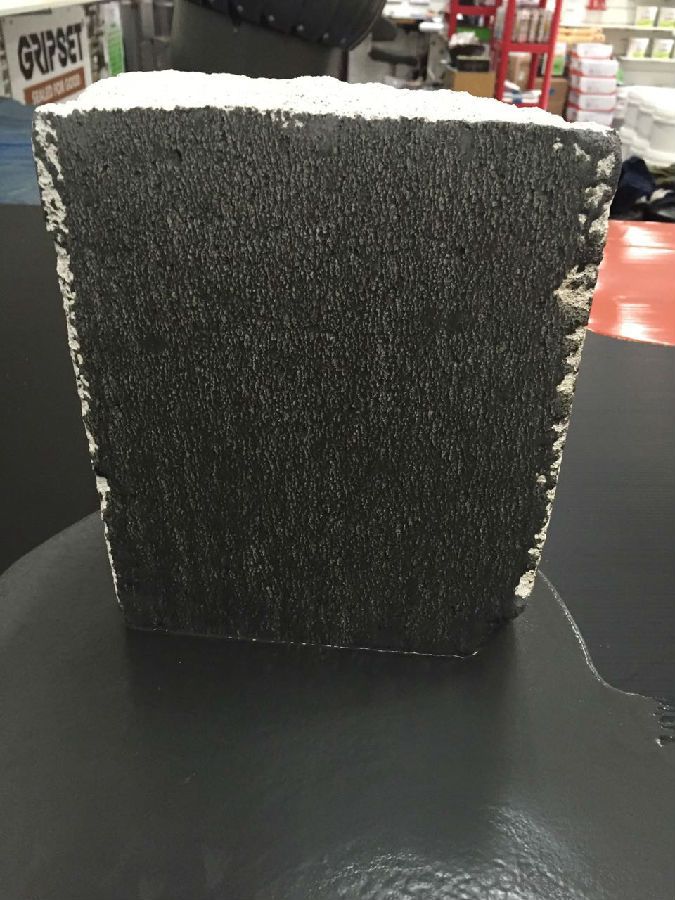

Single Component Polyurethane Waterproof Coating photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q:What is the car waterproof sticker material?

- Engraving process car sticks A. knife engraving process: refers to the computer will be vector graphics input knife machine, the knife will be cut into a preset film shape, and then by hand will be different colors together Finished, and finally in the finished product posted on the surface of a layer of transparent transfer film, after the stickers to remove the stickers; due to knife car paste production process is complex, high cost of materials, currently only suitable for individual car and Che Youhui team Small customization

- Q:Why should the use of high pressure perfusion waterproof plugging method

- High pressure grouting construction principle: is a special high-pressure grouting waterproof material through the high-pressure infusion equipment into the concrete crack structure extended until all the cracks (including the naked eye is difficult to meet) filled with water (water) with the cross-linking reaction, Release a large number of carbon dioxide gas, resulting in secondary pressure, high pressure and secondary pressure will be pressed into the elastomer and filled with all the gaps, to stop the purpose of leakage, it can be said that the best performance of plugging material,

- Q:How can the toilet waterproof works fail?

- Can only do a new waterproof, and now have engaged in the base of the waterproof coating, the effect is very good. It is best to ask professionals to do their own difficult.

- Q:Waterproof material water leakage construction should pay attention to what

- Or to local, if it is a bathroom, it should pay attention to these points: Bathroom waterproof practice: 1, ground handling Before the water treatment, must first find the ground. Leveling layer of construction methods: the base surface with gaps, cracks, unequal defects, with cement mortar repair smooth. So that the base surface must be strong, smooth, clean, dust-free, greasy, wax, release agent, and other debris material. Leveling layer before drying can be waterproof construction, construction should be fire, waterproof. After the completion of the waterproof layer, to be finished product protection, not on the move.

- Q:Oriental rain rain waterproof how to

- 2, Oriental rain rain waterproof coating application If the above content can not accurately explain the East rain rain waterproof paint is good, then continue to look at the East Rainbow waterproof coating since the application of this Examples, I believe that most consumers can not say. Oriental Yuhong waterproof coating with its excellent product performance is applied to the Great Hall of the People, China Millennium Monument, the Three Gorges Hydropower Station, Beijing Metro, Capital Airport, Beijing Wuhuan, Sixth Ring, Beijing-Shanghai high-speed, directly under the central grain depot, China Central Television, National Aquatics Center (Water Cube), National ...

- Q:What decoration materials, light and water, and the wall, the perfect combination of glass

- Between the glass and the wall is generally waterproof with waterproof glue, the specific steps are as follows: First, clean the surface Remove the surface of the joints of water, grease, dust and other pollutants, with a clean cloth to clean all the residue, so that the surface clean and dry. (If it is waterproof glue, the surface should be flat and clean, plastic gap to slightly curved as well.)

- Q:Waterproof mortar expensive or dry mortar expensive

- Waterproof mortar more expensive. Because waterproof mortar compared to dry mortar, to add another waterproofing agent, emulsifier and other substances. Waterproof mortar regardless of the cost or transport are more cost-effective.

- Q:What material waterproofing can be mixed with cement sand

- Waterproof layer used in the cement label of not less than 32.5MPa, the thickness of cement mortar should be 2-3cm, the surface clean and solid without cracks; mortar leveling layer of cement should not be less than 32.5MPa, leveling layer to smooth compaction, finished product maintenance is not low In 5 days.

- Q:What is the difference between finished mortar and cement mortar?

- Finished mortar for dry areas, because the addition of lime, lime water retention is good; cement mortar for wet areas, because the high strength.

- Q:FRP finished brush on what can be waterproof do not fade

- On the surface of the gel coat it is, a lot of gel coat points, the specific performance of what you want, you can communicate with the supplier

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polyurethane Waterproof Coating for Swimming Pool

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords