Polyurethane Sandwich Panels for Roof,Wall and Cold Storage

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Waterproof and fireproof

2.Easy to install

3.Low thermal conductivity

4.ISO9001:2008, CE

5.Color coated steel surface

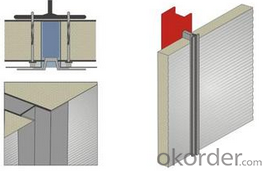

Advantages of SWE Polyurethane Sandwich Panels

1.Heat and sound insulation:The outer steel sheets can maintain the lastingness of the color of the building, and reduce the solar radiation and keep the appropriate indoor temperature. The high quality heat insulation materials are made with the adoption of polyurethane PU and (PIR) polyisocyanurate resin acid hydrogen containing no Chloro-fluoro-carbons (CFC).

2.A degree inflaming retarding:This system can effectively prevent the fire and prevent the fire from spreading during the cross construction and during the use of the boards

3.Environment protection:By learning after the successful experience in environment protection constructions from companies home and abroad and through our scientific analysis, we objectively bear the idea of “low carbon designing, environmental building materials and energy-saving technology” in mind.

4.Super-low heat conductivity:The lowest heat conducting coefficient of the heat insulation boards ensures that, under the condition that the thinnest heat insulation materials are used; the system can meet the energy-saving requirement and offer the strongest basic guarantee to meet the requirement of high standard heat insulation

5.SWE polyurethane roof panel are tightly connected blind nailing

6.Easily and quick installation

The Special Features of SWE Roof Panels

Standard Width(mm) | 1000 |

Length(mm) | 3000≤L≤15000 |

Standard Overall Thickness(mm) | 50 |

Other Overall Thickness(mm) | 50 75 100 |

Outer Face(mm) | 0.5 or above as options |

Inner Face(mm) | 0.4 or above as options |

Core Material | PU |

Average Density of Core(kg/m3) | 40±2 |

Unit Weight of 50mm thickness(kg/m2) | 10.90 |

Thermal Conductivity of Core(w/m . k) | 0.022 |

FAQ

1. Could CNBM sent me some samples for free?

Sure, we can sent samples as your require, only need you to pay the Express fee.

2. Could we inspect the factory when we need?

Sure, welcome to CNBM to give us some suggestion at any time.

3. Does CNBM can guarantee the quality?

Sure, is there is any problem during the contract time, CNBM could supply all the support.

4. What can CNBM do for the costumers?

CNBM could supply the costumers from design, manufacturem shipping and installation, and also after-sell service.

- Q:How are steel structures used in the construction of sports facilities?

- Steel structures are commonly used in the construction of sports facilities due to their strength, durability, and flexibility. Steel beams and columns provide the necessary support for large spans and open spaces, allowing for the construction of grand stadiums and arenas. Additionally, steel can be easily fabricated and modified, enabling architects to create unique and visually striking designs. The use of steel in sports facility construction also allows for faster construction times and cost-effectiveness. Overall, steel structures play a crucial role in creating safe, efficient, and visually appealing sports facilities.

- Q:What is the role of steel bollards in a structure?

- Steel bollards play a vital role in providing protection, security, and traffic control in a structure. They are typically installed to prevent unauthorized vehicle access, protect buildings from accidental collisions, and safeguard pedestrians and property from potential harm. Steel bollards serve as physical barriers and are designed to withstand impact, making them an essential component in maintaining safety and order within a structure.

- Q:How are steel structures used in manufacturing and assembly plants?

- Steel structures are widely used in manufacturing and assembly plants due to their numerous advantages. One of the key benefits is the strength and durability of steel, which allows for the construction of large and complex structures that can withstand heavy loads and harsh environmental conditions. In manufacturing plants, steel structures are used to create the framework for the assembly lines and production areas. They provide a sturdy and reliable support system for the machinery, equipment, and conveyor systems used in the manufacturing process. Steel structures can easily accommodate the installation of overhead cranes, which are essential for lifting and moving heavy materials and finished products. Steel structures also offer flexibility in terms of design and layout. They can be easily customized to meet the specific needs of the manufacturing plant, allowing for efficient use of space and optimal workflow. The open design of steel structures enables the integration of various systems, such as ventilation, electrical wiring, and plumbing, ensuring a safe and functional working environment. Furthermore, steel structures are fire-resistant, making them ideal for manufacturing and assembly plants where the risk of fire is high. Steel does not contribute to the spread of fire and can withstand high temperatures, providing valuable time for evacuation and fire suppression measures. Additionally, steel structures are cost-effective and require minimal maintenance compared to other construction materials. They have a long lifespan and are resistant to rust, corrosion, and pests. This durability translates to reduced maintenance and repair costs, allowing manufacturing and assembly plants to allocate their resources more efficiently. Overall, steel structures play a crucial role in manufacturing and assembly plants by providing a strong, flexible, and cost-effective solution for creating the necessary infrastructure. They ensure the smooth operation of production lines, enhance safety, and contribute to the overall efficiency and productivity of the facility.

- Q:How are steel structures designed for energy-efficient buildings?

- Steel structures for energy-efficient buildings are designed with several key principles in mind. Firstly, the design focuses on optimizing insulation by incorporating thermal breaks and continuous insulation systems. Secondly, the use of high-performance glazing and efficient windows helps to minimize heat transfer. Additionally, steel structures can be designed with natural ventilation systems, daylighting strategies, and efficient HVAC systems to reduce energy consumption. Lastly, the use of sustainable and recyclable materials in steel construction contributes to the overall energy efficiency of the building.

- Q:What is the role of steel in plumbing and water supply systems?

- Steel plays a crucial role in plumbing and water supply systems as it is commonly used for pipes, fittings, and fixtures due to its strength, durability, and resistance to corrosion. It ensures reliable and long-lasting water distribution, especially in large-scale infrastructure projects. Steel pipes can withstand high pressure and extreme temperatures, making them suitable for conveying both hot and cold water. Additionally, steel's versatility allows for customization to meet specific project requirements, ensuring the efficient and safe delivery of water to homes, buildings, and industries.

- Q:What is the load capacity of a steel structure?

- The load capacity of a steel structure can vary depending on factors such as the design, size, and quality of the steel used. However, in general, steel structures are known for their high load-bearing capacity and can support significant weights, making them suitable for a wide range of applications, including buildings, bridges, and industrial facilities.

- Q:What is the edge of the steel structure?

- The main points and methods of construction are as follows:(1) will continue to spread to the roof membrane vertical wall, form a waterproof membrane, flashing a height of not less than 250mm.(2) joints in the roof and the wall of the daughter of vertical handover, mortar leveling layer should be put into a circle or 45 degree slope, brush roll of adhesive, the adhesive sheet density, avoid roll overhead or break, and laying a layer of coil.(3) to receive an flashing coil head fixed on the vertical wall surface coil to prevent decline. The general approach is: cut out a long groove in the vertical wall, reducing coiled material pressed into the groove, and then screw pressure sealing materials filled with waterproof sealing strip, wipe cement mortar protection. The walls on the upper part of the groove shall also be waterproof.Common explanation: flashing refers to the waterproofing roof parapet, cornice or roof wall, its main role is to ensure that the level of the roof cornice and parapet, wall is washed by rain, and the rest of the protection of the roof waterproof layer (not water).

- Q:How are steel structures used in the construction of parking structures?

- Steel structures are commonly used in the construction of parking structures due to their inherent strength, durability, and versatility. The use of steel provides several benefits in terms of design flexibility, construction efficiency, and long-term performance. Firstly, steel structures offer exceptional strength and load-bearing capacity, allowing for the construction of multi-level parking structures that can accommodate a large number of vehicles. Steel is known for its high tensile strength, which means it can withstand heavy loads without deformation or failure. This makes it an ideal material for supporting the weight of numerous cars and the additional loads of ramps, floors, and other structural components. Moreover, steel structures are highly durable and resistant to various environmental factors. Steel is not susceptible to rot, decay, or insect damage, unlike wood or concrete. It is also fire-resistant, which is particularly important in parking structures where the risk of fire is higher due to the presence of flammable materials such as gasoline. Steel's durability ensures the longevity of the parking structure and reduces the need for frequent maintenance or repairs. Another advantage of using steel in parking structure construction is its versatility in terms of design. Steel can be easily shaped and fabricated into a wide range of forms, allowing for the creation of unique and aesthetically pleasing parking structures. This flexibility in design enables architects and engineers to optimize the use of space, create open and well-ventilated structures, and incorporate features like wide spans, cantilevers, and curved elements. Steel structures also offer the possibility of future expansion or modification, as they can be easily adapted to accommodate changing needs or increased parking demand. Furthermore, steel structures are prefabricated off-site, which significantly reduces construction time and minimizes disruption to the surrounding areas. Steel components are manufactured under controlled conditions, ensuring high quality and precision. Once on-site, these prefabricated elements can be quickly and easily assembled, accelerating the overall construction process. This time efficiency is particularly advantageous in parking structure projects, where timely completion is often crucial to meet the growing demand for parking spaces. In conclusion, steel structures play a vital role in the construction of parking structures due to their strength, durability, versatility, and construction efficiency. Their ability to withstand heavy loads, resistance to environmental factors, adaptability in design, and prefabrication advantages make steel an ideal material choice for creating safe, functional, and visually appealing parking structures.

- Q:How are steel structures designed to be resistant to corrosion in acidic environments?

- Steel structures are designed to be resistant to corrosion in acidic environments through various methods. One common approach is to use corrosion-resistant alloys or coatings that provide a protective barrier between the steel and the corrosive environment. Additionally, the design may incorporate proper drainage systems to prevent the accumulation of water or acidic substances, which can accelerate corrosion. Regular maintenance, such as inspections and cleaning, is also crucial to identify and address any signs of corrosion promptly.

- Q:What are the requirements for designing steel agricultural buildings?

- The requirements for designing steel agricultural buildings typically include factors such as durability, strength, corrosion resistance, weather resistance, proper ventilation, sufficient space for livestock and equipment, appropriate lighting, and compliance with local building codes and regulations. Additionally, considerations for efficient use of space, flexibility for future expansion, and cost-effectiveness are also important factors in designing steel agricultural buildings.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polyurethane Sandwich Panels for Roof,Wall and Cold Storage

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords