Polyurethane Foam Sandwich Panel / PU Foam Sandwich Wall Panels / Wall Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

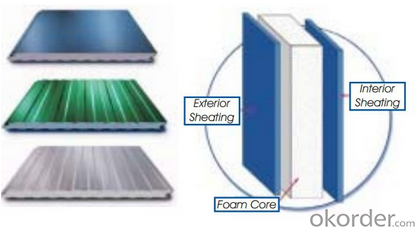

Polyurethane foam sandwich panel / PU foam sandwich wall panels / wall sandwich panel

Product Description

refrigeration panels for sale is adopting colour coating steel sheet as surface panel and polyurethane (PU) as core material.

This product with quick installation and good insulation which is

applied widely in: cold store, ceiling, temporary

house,dormitories,warehouse,workshop and etc.

Specifications:

1. Outer materails specification,

1) Two sides: painted steel sheet, stainless steel sheet and hot-galvanized steel sheet for customers' option

2) Thickness(mm): 0.3~0.8mm

3) Color: According to customer requirement

4) Width: 960mm

5) Length:According to customer requirement

2.Sandwich core: Polyurethane(PU)

Density: 38-40(kg/m3), 40-42(kg/m3), 42-45(kg/m3).

3.Fireproof:According to customer requirement, default is B2 grade

Introduction

PU Sandwich Panel

is fit for the projects which have serious require of keeping warm. Polyurethane core material is considered to the best material in keeping warm and thermal insulation.

The Polyurethane block material become steady after it froth, then combining with metal plates. The characteristics of this technique are: the polyurethane froth, after this chemical reaction is stable, we cut the polyurethane into pieces which with different thickness. The polyurethane sheet material has stable physical performance, it can combine with pre-painted hot galvanized steel sheets or stainless steel sheet, the surface is smooth and the whole performance is excellent.

2.Characteristics

1. sandwich wall panels

(the abbreviation of Polyurethane is PU sandwich panel) have characteristics of high load intensity, small waterabsorptive, and the stability in either low temperature or the high temperature is good, the service life is long, thermal insulation performance is outstanding and so on.

2. Good supporting, heat resistant, sound-insulated, sound absorption, light quality, non-toxic, odorless, green environmental protection.

3. Structural insulated panel system can cementation with the steel plates, the cements, the fiberboards, the bricks and many kinds of materials very strongly, in usual situation, it would not fall off and still strengthen its thermal insulation and waterproofing effects.

4. The unique produce foaming craft made the products have exquisite and even abscesses, the Thermal conductivity is low, the size stability is good, is very suitable for both of the low pressure and the high pressure construction.

5. Polyurethane foam plastics thermal stability is quite good, when the temperature is lower than 120°C, the volume and the intensity have no obvious change, its Thermal conductivity is small, when the density is 0.03kg/m3, the heat conductivity is only 63J(m.h.k)(15cal/m.h.k).

3. Specification

Effective width | 925mm,1000mm,1125mm |

Length | customized. less than 11.8 will be better for shipment |

Materials | PU & Color steel sheet |

Structure | Upper and lower layer: Color steel sheet |

Middle: polyurethane foam board | |

Thickness | Color steel sheet: 0.4-1.0mm |

Density | 38-45kg/m3 |

Color | customized |

Characters | Light in weight, heat insulation, water resistant, hidden screws and antirust,excellent quality and beautiful design. |

Use | various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc. |

4.Product Technical Advantages

1. Tailor made by customers' requirement in terms of colours, thickness, density, and composite alteration.

2. A class fire-resistance( 650.C)fire-resistance period(120min)

3. Excellent thermal & sound insulation and energy saving performace

4. Hidden installation with no visible bolt fixing

5. Outstanding integrity and nice looking

6. Fast and easy installation

7. Excellent durability and strength

5. Anti oxidation

FAQ

The size of the panel can be changed?

Yes, according to the costumer's design.

Can you send samples?

Yes, you noly need to pay for freight charge.

- Q:Air conditioning year after the addition of Calvary is not the reason for refrigeration

- The system after spraying the rigid foam polyurethane insulation layer in the wall to form a continuous seamless overall, winter can avoid the heat bridge, greatly reduce the indoor heat loss; summer can greatly reduce the sun due to the external walls of the heat conduction, and then So that heating, air conditioning, energy consumption, energy saving effect is obvious, can reduce energy consumption, protect the theme structure, to extend the life of the building

- Q:Are sandwich panels suitable for food kiosks?

- Yes, sandwich panels are suitable for food kiosks. Sandwich panels are widely used in the construction industry for their durability, insulation properties, and ease of installation. These panels consist of two outer layers, typically made of metal, and a core material, such as polyurethane foam or rockwool, providing excellent thermal insulation. Food kiosks require a hygienic and clean environment to comply with food safety regulations. Sandwich panels offer a smooth, non-porous surface that is easy to clean and maintain, making them ideal for food kiosks. The panels also provide thermal insulation, keeping the interior cool or warm depending on the climate, which is crucial for storing and serving food at the right temperature. Additionally, sandwich panels are lightweight, which makes them easy to transport and assemble, allowing for quick setup and relocation if needed. They are also structurally strong, providing stability and security for the kiosk. Overall, sandwich panels are a suitable choice for food kiosks due to their durability, insulation properties, hygienic surfaces, and ease of installation.

- Q:Are sandwich panels suitable for automotive showrooms?

- Yes, sandwich panels are suitable for automotive showrooms. Sandwich panels are made up of two outer layers or skins with a lightweight core material in between, providing excellent strength and insulation properties. These panels are versatile and can be used for various applications, including building facades, partitions, and interior walls. In automotive showrooms, sandwich panels can be used for constructing walls, ceilings, and even floors. They offer several benefits that make them ideal for this environment. Firstly, sandwich panels provide excellent insulation, which helps maintain a comfortable temperature inside the showroom, regardless of the weather outside. This is crucial for creating a pleasant environment for both customers and staff. Additionally, sandwich panels are lightweight and easy to install, allowing for quick and efficient construction. This is beneficial for automotive showrooms, as they often have tight deadlines and need to be operational as soon as possible. The panels can be easily cut and shaped to fit specific design requirements, allowing for flexibility in creating unique and attractive showroom layouts. Sandwich panels also offer good noise reduction properties, ensuring a quieter environment within the showroom. This is important for providing a comfortable atmosphere for customers and allowing them to focus on the vehicles on display. Furthermore, sandwich panels are durable and require minimal maintenance. They are resistant to corrosion, moisture, and fire, ensuring a long-lasting and safe solution for automotive showrooms. Additionally, the outer layers of the panels can be customized with various finishes and colors, allowing for branding and aesthetic preferences to be incorporated into the showroom design. Overall, sandwich panels are a suitable choice for automotive showrooms due to their insulation properties, ease of installation, noise reduction capabilities, durability, and customization options. They provide a cost-effective and efficient solution for creating a functional and visually appealing environment to showcase vehicles.

- Q:Are sandwich panels suitable for train stations?

- Yes, sandwich panels are suitable for train stations. They are lightweight, strong, and provide excellent insulation properties. Additionally, sandwich panels can be easily installed and offer a wide range of design options, making them a practical and efficient choice for train station construction.

- Q:How does the wall rock wool sandwich panel be installed?

- will be fixed on the wall insulation material, play a warm and warm role in warm technology

- Q:Can sandwich panels be used for noise barriers?

- Sandwich panels are indeed a viable option for noise barriers. Typically, these panels consist of two outer layers made from rigid materials like metal or wood, with an insulating layer in between. This insulating layer functions to absorb and dampen sound waves, making sandwich panels an effective solution for noise barriers. The insulating material used in sandwich panels can vary, with options such as mineral wool or polyurethane foam, both of which possess excellent sound absorption properties. These materials are specifically designed to trap and dissipate sound energy, effectively preventing it from passing through the barrier and reducing noise levels on the opposite side. When it comes to noise barriers, sandwich panels can be customized to meet specific requirements for noise reduction. By adjusting the thickness and density of the insulating layer, the desired level of sound insulation can be achieved. Additionally, the outer layers can be designed to either reflect or absorb sound, depending on the desired acoustic performance and aesthetic preferences. There are several advantages to using sandwich panels for noise barrier applications. Firstly, they are lightweight, making them easy to install and transport. Furthermore, they possess a high strength-to-weight ratio, providing structural integrity to withstand environmental factors such as wind and vibrations. Lastly, sandwich panels can be engineered to be durable and resistant to corrosion, ensuring long-lasting performance in outdoor environments. To summarize, sandwich panels are an ideal choice for noise barriers due to their sound absorption properties, customization options, and durability. They effectively reduce noise levels, creating a quieter environment for various applications, including highways, factories, residential areas, and commercial buildings.

- Q:Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- It should be, for example, naphthalene anthracene, and several rings are capable of forming a closed conjugate system. Generally speaking, more than four benzene rings are fused (for example, 1.2-benzo, 3-methyl Anthracene, etc.) are mostly carcinogenic substances, which are mostly anthracene derivatives, the relationship between the mechanism of carcinogenesis and structure is not yet fully understood ...

- Q:What is the difference between rock wool sandwich panels, EPS sandwich panels and polyurethane sandwich panels?

- When the top of the ventilation tube can not be extended out of the roof, the following ventilation can be used: ①, set the side wall ventilation tube ②, by setting the confluence of the ventilation pipe after the extension of the side wall to extend above the roof ③, set up self-circulation ventilation pipeline system , the following circumstances should be set up ventilation riser: ①, when the drainage pipe to take the sanitary equipment drainage design flow than in Table 449 only set the top of the drainage pipe drainage pipe maximum design drainage capacity ②, the building standards require a high multi-storey residential and public buildings, 10-storey and 10-storey high-rise building life drainage riser , the following drainage pipe should be set up annular ventilation pipe: ①, connecting four and more than four sanitary ware and the length of more than 12m of the drainage pipe ②, connecting 6 and 6 or more toilet toilet cross pipe ③, do not exceed the above provisions, but the nature of the building is important, the use of high requirements or set the device when the ventilation tube , the health, quiet requirements of the building, the living drainage pipe should be set to ventilator tube , the drainage pipe at all levels of the building shall be provided with an annular ventilation pipe, and shall be provided with a main ventilation riser or a secondary ventilation riser for the connection of the layers , ventilation riser shall not accept the equipment of sewage, waste water and rain; not connected with the duct and flue

- Q:What is the difference between the board and the core board? The The

- Cantilevered scaffolding should use biaxial symmetrical section of the steel, which is usually said I-beam models and anchors need to calculate each other, according to the stairs to set the shape

- Q:Sun room roof was originally glass, so hot, want to add a layer of foam in the above sandwich panels, what sticky more solid anti-aging!

- This kind of thing is generally money! The

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polyurethane Foam Sandwich Panel / PU Foam Sandwich Wall Panels / Wall Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords