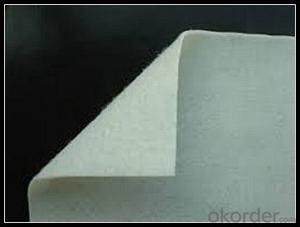

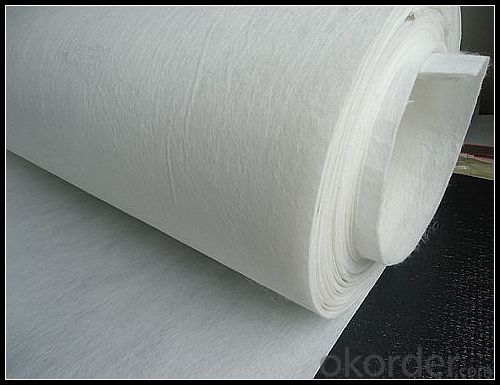

Polypropylene Nonwoven Geotextile with High Stabilization and Performance for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Characteristic of Geotextile

Superior water permeability, filtrability and deformation adaptive faculty

Resist to corrosion and also anti-aging

Geotextile has high water diversion property, it can form drainage passageway, transpire the surplus liquid and gas

High water permeability even under the pressure of soil and water

Spread, transfer or decompose the concentrate stress effectively to avoid the soil be damaged by outside affection

To prevent the freestone upper and lower level, soil and concrete mixed

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:Can geotextiles be used in coastal dune stabilization projects?

- Yes, geotextiles can be used in coastal dune stabilization projects. Geotextiles are commonly used in such projects to create barriers that help prevent erosion, promote vegetation growth, and provide stabilization to the dune system. They can effectively control sand movement, prevent sand loss, and enhance the stability and resilience of coastal dunes.

- Q:How are geotextiles used in agricultural applications?

- Geotextiles are used in agricultural applications to control soil erosion, improve water drainage, and provide stabilization for slopes. They are often placed under roads, walkways, and erosion-prone areas to prevent soil erosion and maintain the integrity of the land. Additionally, geotextiles can act as a filter to separate fine particles from larger ones, allowing for better water drainage and preventing clogging in drainage systems. Overall, geotextiles play a crucial role in enhancing agricultural practices and preserving the health of the soil.

- Q:How do geotextiles help with slope stabilization?

- Geotextiles help with slope stabilization by providing reinforcement and retaining soil on slopes. They act as a barrier, preventing erosion and the movement of soil particles, while still allowing water to pass through. This helps to maintain the stability of slopes and prevents landslides or slope failures.

- Q:What are the key considerations for geotextile installation in areas prone to landslides?

- The key considerations for geotextile installation in areas prone to landslides include the selection of appropriate geotextile material, understanding the slope characteristics, conducting a thorough site investigation, ensuring proper anchoring and securing methods, and collaborating with experienced geotechnical engineers for design and installation guidance. Additionally, considering the long-term performance, maintenance requirements, and monitoring of the geotextile system is crucial to ensure its effectiveness in mitigating landslide risks.

- Q:How do geotextiles help in preventing soil compaction?

- Geotextiles help in preventing soil compaction by providing a barrier between the soil and external forces. They distribute the load evenly across the surface, reducing direct pressure on the soil and preventing it from being compacted. Additionally, geotextiles improve soil drainage, allowing excess water to flow through and preventing waterlogged conditions that can lead to compaction.

- Q:What is the waterproof selection of artificial lake? How to build?

- There are many features ah

- Q:Geotextile what are the specifications of the ah?

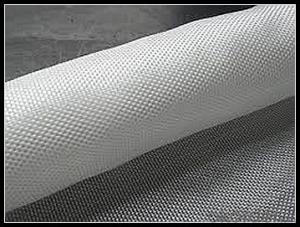

- Geotextile is first divided into short wire geotextile and filament geotextile. Their specifications generally according to the weight to count, small equipment, geotextiles are mostly between 80g-380g, and now some mature domestic enterprises generally can do between 100g-1500g short wire and filament geotextile. How many grams of this can be customized between. It should be noted that the same specifications of the short wire geotextile price than the filament geotextile to 30% cheaper, but the technical strength index than the long geotextile cloth nearly 50%.

- Q:How do geotextiles contribute to pavement performance?

- Geotextiles contribute to pavement performance by providing reinforcement, filtration, and separation functions. They enhance the structural integrity of the pavement by distributing loads and reducing the potential for cracking and rutting. Geotextiles also help in preventing the mixing of different layers of pavement materials, improving drainage, and reducing the intrusion of fine particles into the pavement layers. Overall, geotextiles improve the durability, longevity, and overall performance of pavements.

- Q:What are the maintenance requirements for geotextile-reinforced retaining walls?

- The maintenance requirements for geotextile-reinforced retaining walls typically include regular inspections for signs of erosion, damage, or structural issues. Additionally, any vegetation growing near the wall should be monitored and removed if it poses a threat to the integrity of the structure. It is also important to ensure proper drainage and prevent water buildup behind the wall. Regular cleaning and removal of debris is necessary to avoid blockages and maintain the functionality of the drainage system. Overall, following manufacturer guidelines and conducting routine maintenance activities will help ensure the longevity and effectiveness of geotextile-reinforced retaining walls.

- Q:Is the polypropylene composite geotextile and the polyethylene composite geomembrane the same?

- Geotextiles and geomembranes are not the same, but they complement each other to meet the engineering requirements. First introduced under the geotextile: geotextile is the state for civil engineering in the construction of a new type of construction materials, by filament or short fiber through different equipment and process shop into a mesh, and then after acupuncture and other processes to different Fibers are intertwined with each other, tangent to the fabric to make the fabric normal, so that the fabric is soft, plump, thick, stiff, to meet the different thickness to meet the requirements, according to the length of silk is divided into filament non-woven geotextile or short wire Non-woven geotextile, filament tensile strength higher than the short wire. Fibrous soft with a certain tear resistance. The main role is: filter, filter, reinforcement role. Specifications from 100 grams per square meter to 800 grams per square meter. The main material for the polyester fiber, with excellent permeability, filtration, durability deformation adaptability, and has a good flat drainage capacity (see below) Geomembrane to plastic film as anti-seepage substrate, and non-woven composite Made of geotextile impermeable material can be divided into two cloth a film, a cloth a film, its impermeability depends mainly on the plastic film impermeability. The geomembrane is a waterproof barrier material with the polymer of the polymer chemical material as the basic raw material. The proportion of small, strong extension, high adaptability to adapt to deformation, corrosion resistance, low temperature, good frost resistance. (See below)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polypropylene Nonwoven Geotextile with High Stabilization and Performance for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords