Polypropylene Nonwoven Geotextile Road Used Geotextile

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polypropylene Nonwoven Geotextile Road Used Geotextile

Desciriptions:

Polypropylene Nonwoven Geotextile Road Used Geotextile are the preferred products for lining projects requiring low permeability ,corrosion protection , exceptional chemical and ultraviolet resistance properties , which makes them extremely cost effective for many applications such as waste landfill , storage reservoirs ,canals , powr plants in energy ,

vapor barriersand waste water treatment in the line of industry and aquaculture and agriculture projects.

Specifications:

| Weight / Mass | 100gsm - 800gsm |

| width | Within 8 m |

| longth | 50-100m/roll (at request) |

| Material | PP / PET |

| Color | Black , white , grey |

| Certification | CE/ISO9001 |

| Manufacturing method | nonwoven / woven |

Characteristics:

Easy process and high output rates

Excellent distribution of carbon black

Consistent quality and low failure rate

Excellent resistance and good waterproof ability

Good welding

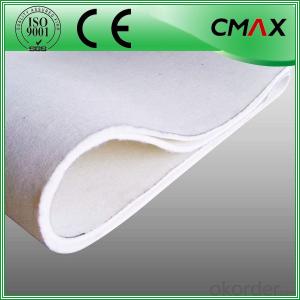

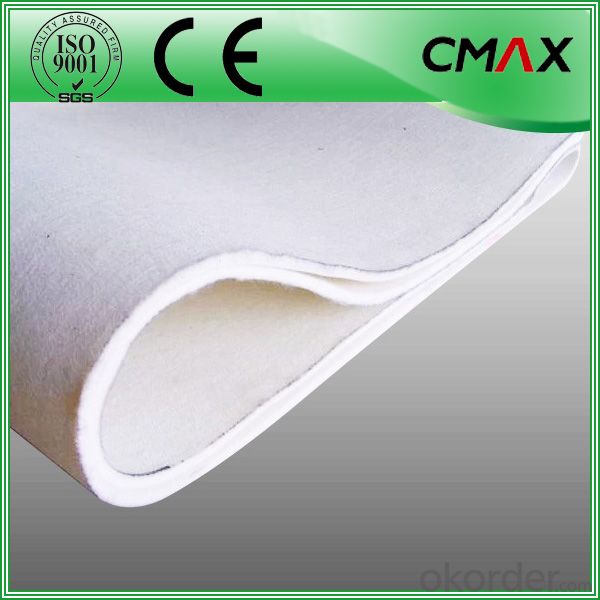

Details of our products:

Produce process:

Applications:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Packing and shipping:

♦ Packing:in plastic film bag(keep away from moisture) and PP bag or as your customize.

♦ Shipping:By sea or as your customize

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

HDPE Geomembrane Price

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q:What are the different factors to consider for geotextile selection in mining applications?

- When selecting geotextiles for mining applications, several factors need to be considered. These include the required strength and durability of the geotextile to withstand the specific mining conditions, such as heavy machinery, abrasion, and chemical exposure. The permeability and filtration capabilities of the geotextile are also crucial to ensure proper drainage and prevent clogging. Additionally, factors like installation ease, cost-effectiveness, and compliance with environmental regulations should be taken into account to make an informed decision for geotextile selection in mining applications.

- Q:Tunnel longitudinal drainage pipe with geotextile wrapped after the need for waterproof board wrapped, why can not be wrapped with a waterproof board

- You should say that the drainage pipe should be seepage of plastic blind tube it. Geotextile wrapped in the role is to play a filtering effect, filter the water to drain the sediment. Chong Hong geotextile material manufacturers

- Q:How do geotextiles help in the reduction of subgrade pumping?

- Geotextiles help in the reduction of subgrade pumping by acting as a filter and allowing water to pass through while preventing soil particles from being washed out. This helps to maintain the stability and strength of the subgrade, preventing the pumping of fine particles and water to the surface.

- Q:Can geotextiles be used in landscaping projects?

- Yes, geotextiles can be used in landscaping projects. Geotextiles are commonly used to control soil erosion, separate different soil layers, and stabilize slopes. They can also help with weed control and provide drainage in landscaping projects.

- Q:What are the challenges associated with geotextile installation?

- One of the main challenges associated with geotextile installation is ensuring proper alignment and placement of the material. Geotextiles need to be installed in a specific manner to effectively perform their intended functions, such as erosion control or soil stabilization. Achieving the right alignment can be difficult, especially in areas with uneven terrain or limited access. Another challenge is securing the geotextile in place. Since these materials are often lightweight and flexible, they can easily shift or become displaced during installation. Proper anchoring techniques, such as using staples or pins, are necessary to prevent movement and maintain the integrity of the installation. In addition, the type and condition of the underlying soil can pose challenges. Geotextiles require a stable and well-compacted base for optimal performance. If the soil is soft or unstable, additional measures such as soil stabilization techniques or geogrids may be necessary to ensure proper installation. Lastly, weather conditions can also impact geotextile installation. Wind, rain, or extreme temperatures can make the process more difficult and may require additional precautions or delays. Proper planning and coordination with weather forecasts are essential to mitigate these challenges and ensure a successful geotextile installation.

- Q:How do geotextiles help in preventing the growth of weeds?

- Geotextiles act as a physical barrier that prevents weed growth by blocking sunlight, which is essential for weed germination and growth. Additionally, they hinder weed seed transportation and provide a stable base for other materials like mulch, further reducing weed growth.

- Q:What are the different methods of geotextile installation?

- There are several different methods of geotextile installation, including trenching, direct placement, sewing, stapling, and adhesive bonding. Trenching involves excavating a trench and placing the geotextile fabric in it before backfilling. Direct placement involves simply unrolling and placing the geotextile on the desired surface. Sewing involves stitching the geotextile to another fabric or material, providing additional strength. Stapling involves using staples or nails to secure the geotextile to the ground or other surfaces. Adhesive bonding involves using specialized adhesives to attach the geotextile to the desired substrate. The choice of installation method depends on the specific project requirements and the type of geotextile being used.

- Q:Are geotextiles resistant to acid degradation?

- Yes, geotextiles are generally resistant to acid degradation. They are designed to withstand various environmental conditions, including exposure to acids, and are made from materials that have high chemical resistance. However, the level of resistance may vary depending on the specific type of geotextile and the concentration and duration of acid exposure.

- Q:How do geotextiles compare to traditional construction materials?

- Geotextiles offer several advantages over traditional construction materials. Firstly, geotextiles are lightweight and easy to handle, making them more convenient to transport and install. Secondly, they have excellent filtration properties, allowing for effective drainage and preventing soil erosion. Additionally, geotextiles are highly durable, resistant to rot and chemicals, and can withstand harsh environmental conditions. They are also relatively cost-effective compared to traditional materials, reducing project expenses. Overall, geotextiles provide a versatile and efficient solution for various construction applications.

- Q:Can geotextiles be used for erosion control in river levees?

- Yes, geotextiles can be used for erosion control in river levees. Geotextiles are specifically designed to stabilize soil and prevent erosion, making them an effective solution for reinforcing river levees and protecting them from erosion caused by water flow.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polypropylene Nonwoven Geotextile Road Used Geotextile

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords