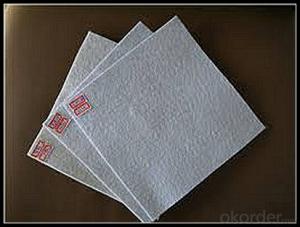

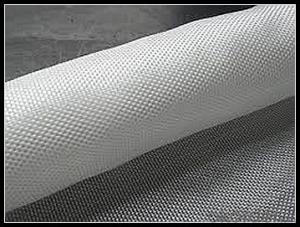

Polypropylene Filter Non-woven Geotextile Farbic Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1) Weight / Mass: 100g/m2-1500g/m2

2) Width: Within 8 m (1m-8m)

3) Length: 50m-100m/roll (as request)

4) Material: PP / PET

5) Color: Black , white , grey and other color

Applications

Filtration

gabions and river mattresses

roads

concrete retaining walls.

Separation

the separation of good and poor roadway layer work materials

roads over soft soils.

Roadway lining

provides waterproofing qualities for layer works and wearing courses.

Drainage of

sports fields

railway tracks

behind concrete walls & embankments.

Membrane liner protection

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:Geotextile water filter?

- Geotextile from the filter, filter the role of water, but soil, I am specializing in the production of geotextiles

- Q:What are the different geotextile installation equipment and tools?

- Some of the different geotextile installation equipment and tools include: 1. Excavators: Used for site preparation and excavation work. 2. Dump trucks: Used for transporting geotextile materials to the installation site. 3. Spreaders: Used for evenly distributing the geotextile material over the designated area. 4. Tensioners: Used to ensure proper tension and alignment of geotextile materials during installation. 5. Staple guns: Used to secure the geotextile material to the ground or other surfaces. 6. Seamers: Used to join different sections of geotextile material together. 7. Pneumatic rollers: Used for compacting and smoothing the geotextile material once it is installed. 8. Geotextile cutting tools: Used to accurately cut the material to the required size and shape. These tools and equipment help to ensure proper installation of geotextile materials, which is crucial for their effectiveness in various applications such as erosion control, soil stabilization, and drainage systems.

- Q:What is the effect of temperature on geotextile performance?

- The effect of temperature on geotextile performance can vary depending on the specific type and composition of the geotextile. In general, higher temperatures can cause geotextiles to become more flexible and pliable, which can enhance their ability to conform to irregular surfaces and provide better soil stabilization. However, extremely high temperatures can also lead to thermal degradation and loss of strength in certain geotextiles. Conversely, colder temperatures can make geotextiles stiffer and less flexible, potentially reducing their ability to perform certain functions such as filtration or separation. Therefore, it is crucial to consider the anticipated temperature conditions when selecting and designing geotextiles for specific applications.

- Q:Can geotextiles be used in embankment reinforcement?

- Yes, geotextiles can be used in embankment reinforcement. Geotextiles are commonly used in civil engineering projects to improve the stability, strength, and durability of soil structures such as embankments. They are placed within the soil layers to provide reinforcement, filtration, and drainage capabilities, reducing the risk of erosion and enhancing the overall performance of the embankment.

- Q:Basement roof cover soil thickness and geotextile shop in what position,

- The size of the thickness of the roof cover of the basement garage is in the specification of the air defense design

- Q:What is geotextile, what role

- Geotextile is a new type of building materials, raw materials are polyester, acrylic, nylon and other polymer polymer synthetic fiber. In accordance with the manufacturing method is divided into: there are two types of geotextile and non-woven geotextile. Geotextile with anti-seepage, anti-filtration, drainage, isolation, reinforcement, protection, sealing and other functions, it with the conventional masonry and concrete material seepage effect compared to a low investment, simple construction process, short duration Infiltration effect is good, the channel effective use of high coefficient. Water conservancy engineering dams and slope protection filter, channel isolation, seepage control; road, railway, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, drainage; , Geotextile has been widely used in the field of infrastructure construction, and has been gradually applied in the field of infrastructure construction, and the use of geotextile In a wider area.

- Q:How are geotextiles used in landfill construction?

- Geotextiles are used in landfill construction to provide separation, filtration, and reinforcement functions. They are placed between the layers of soil and waste materials to prevent the mixing of different materials, promote proper drainage, and enhance the stability and strength of the landfill structure.

- Q:what do you mean nonwoven geotextiles ???

- please refer the folowing url to know all the details about non woven geo textiles

- Q:How do geotextiles help in preventing piping in dams?

- Geotextiles help in preventing piping in dams by providing a strong and stable barrier against soil erosion. They are placed within the dam structure to reinforce the soil and prevent it from being washed away by the flow of water. This helps in maintaining the integrity of the dam and preventing the formation of internal erosion channels or "piping". Geotextiles also improve the filtration properties of the soil, allowing water to pass through while retaining fine particles, which further helps in preventing piping.

- Q:What are the standards and specifications for geotextiles?

- The standards and specifications for geotextiles vary depending on the specific application and use of the geotextile. However, some common standards and specifications include physical properties such as tensile strength, elongation, puncture resistance, and filtration properties. Additionally, standards may also address factors like UV resistance, chemical compatibility, and installation guidelines. These standards ensure that geotextiles meet the desired performance requirements and are suitable for their intended use in various geotechnical and civil engineering applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polypropylene Filter Non-woven Geotextile Farbic Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords