Polyethylene filling masterbatch for PE PP PS ABS

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyethylene filling masterbatch is a kind of micron-sized Calcium Carbonate masterbatch pure withraw material PE,PP or styrene resin as the carrier.

Customers decide the amount according to theneeds,it has the good physical propertities, the dispersity, stability and does not affect the processing precision of machine screw.

Such masterbatch can be widely used in PE.PP.PS.ABS .

All kinds of plastic products,such as PE plastic bags,plastic injection.

Application: Woven bags,flexible freight bags

Package: packed by woven bags,25kg per bag,store in a dry place.

Advantage of Masterbatch:

1.This series color masterbatches are of high concentration pigment with bright colors.

2.When they are used in resins, it shows better dispersing and stablility performance.

3.Also the mixture has the highest mechanical intensity preservation rate.

4.A broad standard color range available from stock as well as tailor made products develop according to customer requirements.

Features of Masterbatch:

-Standard, universal, or custom colors

-Carriers optimized for easy processing

-Production orders shipped in 5 days

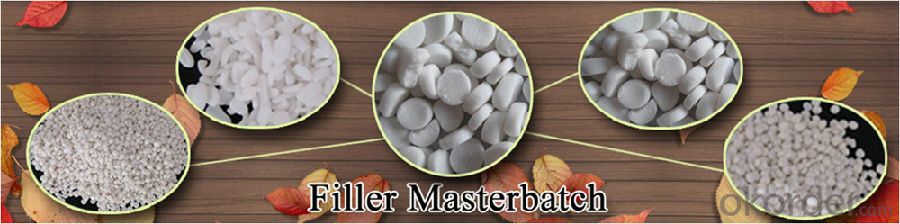

Product Pictures

- Q:What's the difference between recycled plastic bucket and plastic bucket made of raw material?

- The biggest difference is strength. Do good strength, good performance. Recycled materials are generally impure and contain many fillings which are brittle and easily damaged.

- Q:What two ingredients fit together to solidify like plastic?

- What is the material of plastics? This is important because even the adhesive with high bond strength can not be well adhered to on some surfaces, such as PTFE.

- Q:PP plastic stool surface with those raw materials, what is the ratio?

- PP is crystalline polymer. PP is the most common plastic, and the density is only 0.91g/cm3 (smaller than water).

- Q:What does plastic material include?

- The main raw material of plastics is oil and natural gas, that is, carbon hydrogen compounds. First, the appropriate large molecules in petroleum and natural gas are extracted, first split into monomers, and then polymerized into polymers to become plastic.

- Q:What are the main biodegradable plastic bags made of?

- At present, developed a new biodegradable plastic, its composition is polyvinyl alcohol starch plus photosensitizer synthesis, polyvinyl alcohol was easy to degrade than polyethylene, adding photosensitizer can absorb sunlight to accelerate the degradation by plastic, starch can promote the degradation of plastic in soil speed. As a result, this new biodegradable plastic is easier to degrade than the former, and it decomposes into a substance of simple molecular structure, such as carbon and water, which is more environmentally friendly.

- Q:What are the plastic raw materials for this purpose?

- From the bathroom supplies we use when we wake up, the tableware we use for breakfast, the stationery we use for work and study, the seat cushion for sleeping, the mattress, and the shell of TV set, washing machine and computer

- Q:What kind of material is the raw material of plastic pipes?

- Plastic pipe raw material is plastic particles, according to the pipeline production processing performance requirements, with the different requirements of finished products, there are different manufacturers grades, grades and performance differences.

- Q:What is the difference between ABS plastic raw materials and recycled materials? Or how to distinguish between raw materials and recycled materials?

- 1. recycled material is not natural (ABS is yellow).2. non black pellets with black spots are recycled.3. the impurity in the aggregate is the recycled material.4. of the voids in the pellets are recycled.5. do MFI test, the result is more than 10% of indicators are recycled material.6., feed heating, smell, smoke, melting temperature is low, fast flow is recycled material.

- Q:What type of raw material is used in plastic bags? The brightness is good. It blows out as bright as a mirror! That kind of transparency!

- LDPE high pressure 2424H, Lanzhou petrochemical, LLDPE, 7042N, Lanzhou petrochemical. Transparency can reach 90%. The temperature should be controlled during blowing.

- Q:What are the raw materials for vest plastic bags?

- Polyvinyl chloride, referred to as PVC, and the formula is (CH2 - CH2) n, is the most important kind of vinyl polymer, is the world's second largest plastic varieties after polyethylene. In China, the yield is the first in plastics. In the printing industry, packaging production of books, folders, tickets and other frequently used PVC calendered film cover color and transparent glazing film.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polyethylene filling masterbatch for PE PP PS ABS

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products