polyethylene conduit with an integrated toning wire

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

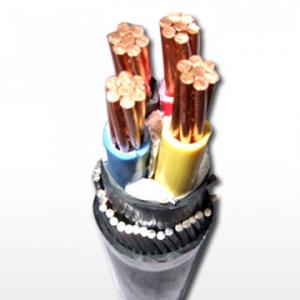

conduit is made from high quality high-density polyethylene (HDPE). The conduit meets industry standard wall thickness in ¾,1,1¼,1½,and 2 inch diameters. The polyethylene is blended with a premium UV stabilization and protection package. Our unique toning wire is 18-gauge copper clad steel (CCS) coated with a fluoropolymer jacket. The wire is located within a channel built onto the inner wall of the conduit. An 18-gauge wire was selected to maintain wall thickness and provide optimal tone carrying characteristics. CCS provides the necessary amount of copper to carry a tone over long distances and a steel core that is more durable than a solid copper wire. The fluoropolymer allows the wire to move independently of the conduit eliminating stresses on the wire and conduit. The fluoropolymer coating also provides critical insulative and corrosion protection to the 'exposed' wire. A Fluoropolymer compound was selected as the tone wire coating because it offers higher resistance to chemicals,water,and abrasion relative to plastics.

Tone wire located within a channel builtt onto the inner wall of conduit for easy location

High density polyethylene material for superior resistance to cracking or shattering of conduit

UV protection to protect from cracking during storage or when used as a ground riser

Continuous length conduit installs faster than PVC stick pipe

Provides excellent cable removal and replacement capabilities

Available with pre-installed CommScope cable or pull line

Density Test Method ASTM D792A

Density, maximum 0.955 g/cm³

Density, minimum 0.941 g/cm³

Design Standard ASTM D335005

Environmental Stress Crack Resistance Failure rate of 10% within 96 hours

Environmental Stress Test Method ASTM D1693, ESCR Condition B

Flexural Modulus, minimum 552 N/mm² | 80000 psi

Flexural Property Test Method ASTM D790

Hydrostatic Design Basis Not pressure rated

Hydrostatic Design Test Method ASTM D2837

Material Type High density polyethylene (HDPE)

Melt Flow Rate Test Method ASTM D1238

Melt Flow Rate, maximum 0.39 g/10 min

Tensile Property Test Method ASTM D638

Tensile Strength at yield, minimum 21 N/mm² | 3000 psi

Minimum Bend Radius, unsupported 660.4 mm | 26.0 in

Pulling Tension, maximum 1043.3 kg | 2300.0 lb

Pulling Tension Note Applies to products manufactured after December 31, 2012

Pull Line Specifications

Breaking Strength 567.0 kg | 1250.0 lb

Material Type Polyester

Pull Line Type Tape

Tone Wire Specifications

Conductor Diameter 1.0236 mm | 0.0403 in

Conductor Elongation, maximum 30 %

Conductor Gauge 18 AWG

Conductor Material Type Copperclad

steel (CCS)

Conductor Resistance 30.0 ohms/kft

Conductor Tensile Strength, minimum 345 N/mm² | 50000 psi

Conductor Type Solid

Regulatory Compliance/Certifications

Agency Classification

ISO 9001:2008 Designed, manufactured and/or distributed under this quality management system

* Footnotes

Environmental Stress Crack Resistance ESCR—Environmental Stress Crack Resistence

- Q:is there a cable for UPS where i can connect this kind of adapter?

- You local should have the cable you need...

- Q:I've just bought myself a new motherboard for my 9800 GT but it isn't picking it up and allowing me to install it's drivers. I have noticed an extra plug on the back of the card and wondered if it maybe needed an extra power plug to it? If not, what else could be the problem?

- everything should of came in the box, if it was connected correctly it would read the new card. once its running, you'll be satisfied.

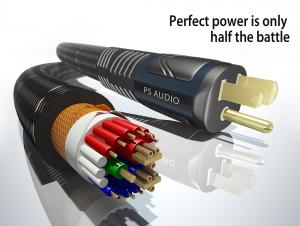

- Q:NE1 have a surge protector and power filter for there home theatre stuff? If so what is the model and did it make a difference? I have RF grounding problem through my cable and was wondering if the moster cable boxes would help clean up the signal. I have to wrap a wire around the coax cable and ground it to something to make SOME not all of the noise dissappear. (lines rising from bottom to top of picture) Obviously I want a more definate and permant solution. Thanks.

- Yes, a power conditioner will not only clean the power, but take out any humming or ground loop issues. I noticed a difference in audio and video. I have a Monster Power MKIII 3600. I got it for $200, on sale at Circuit City a year ago. I highly recommend it if you have a multi-component home theater or expensive TV. I have a 50 plasma, DVD player, Comcast box, AV receiver, Xbox and Nintendo Wii. They are all connected through the power conditioner.

- Q:I bought a ATI HD2600 Pro Video card todayHere is the list of what my computer specs,Pentium 4 2.53 GHzCurrent Videocard - Rage Fury Pro 2000 Pro (Microsoft Corp)slot - AGP 8xmotherboard - BCS PT800CE - Aram - 512MB PC2700 333 MHZ (2 of them) 1G ramMonitor - 19ViewSonic VA902B 1280 x 1024im not sure about my battery wattage is enough for the card or not. it says 400+ battery supply is recommended, could it be the reason?when i plugged in my monitor cable to the adaptor for dvi to AGP and connect it to my video card, HD2600 Pro. I turn the computer on, but the monitor do not turn on. it just stays as it was. i have made sure that the monitor is on and all the plugs are right i do not understand what happen. BTW, when i try to check my bios settings, i am able to access it after putting in my password, but it won't let me update, everything is in blue, except some are quot;press enterto allow me to see the details. why is that? please help me...please please.

- it might if so the plugin looks like a floppy drive plug four pins if you got the card new and it has an adaptor you will have to use it most ati cards that have external power syncronize with the hard drive .

- Q:Forced shut down pc now it has no power just a buzzing sound when the power cable is plugged in

- Time to replace the power supply.

- Q:10KV cable is directly from the nearest substation led to the power distribution room, how some people say that from the transformer can not understand what the meaning of more

- Low-voltage power cable, also known as: low-voltage power cable. The voltage rating is 0.6 / 1KV. National Standard No .: GB / T-2008. The voltage rating of the control cable is 450 / 750V. National Standard No .: GB / T9330-2008. The voltage rating of these two cables, the country has a clear standard. Can not be changed.

- Q:Cable 3 (4 × 185 + 1 × 95) What does it mean?

- According to Article 22.7.1 of the Electrical Design Code for Civil Buildings JGJ16-. the transmission lines and the electronic information system transmission lines shall be laid separately and shall be shielded when they are close to the laying of them in parallel by the construction conditions. High-voltage cable under normal circumstances is not allowed and weak cable with the ditch laying. If the relevant control cable does need to be with the high-voltage cable ditch, should be laid on both sides of the laying and keep the distance, but also pay attention to control cable shielding measures.

- Q:My laptop battery ran out because my power cable broke. I need to take out my files before I get it repaired. Is there a way I can charge my laptop? (HP Pavilion Entertainment)

- Sounds like you just have to buy a new cable.

- Q:the cable that comes out of the ocean and goes onto the island. Sayid finds it

- The underwater Dhrama Looking Glass station. Remember from the season finale of season 3 I believe, it's where Desmond and Charlie swam to to press the button thing to allow communication with the outside world, but those two women were there and then Mikhail showed up and Charlie ended up drowning after Mikhail threw a grenade at the control room Charlie was in, but before Charlie drowned he managed to tell Desmond that the freighter was not Penny's boat.... ringing a bell? The cable was to provide power to it.

- Q:I forgot the power cable for my PS3 at a friends house and was wondering if the power cable from my computer would work. It would fit and everything, but would it mess up the system?

- The power cables are identical from PC to PS3.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

polyethylene conduit with an integrated toning wire

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords