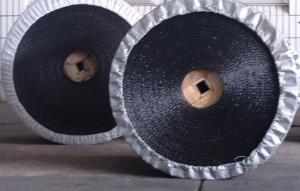

Polyester Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| ||||||||||||||||||||||||||||||||||||||

- Q:How much is a tin strap?

- It depends on what kind of packing you need, whether it's new or recycled. And the tape depends on his width and thickness. Do you have a requirement for the length of each volume?.

- Q:What is the reason that the packing machine can not be put in?

- Wear and wear wrong,2, catch a foreign body obstruction

- Q:Blue belt principle is what?

- Blue will be packaged with packaging with heating to proper temperature in the air - water vapor to form a blue layer of the surface process.

- Q:Packing belt

- Alias strap. Packaging belt (strapping) is made of polyethylene, polypropylene resin and cold rolled strip as the main raw material, and also made of nylon and polyester as raw material. It is made by extruding and drawing in one direction and hot at the same time. In addition to corrugated box sealing, strapping, hot rolled steel coil strapping, cold rolled steel coil strapping, glass, tubes, materials, fruits, etc. can also be bundled.

- Q:Is the profit margin of the packing belt line large?

- Profit in general, buy materials to 6000 far, the finished product in the market price more than 6000 yuan, remove the rent, electricity, wages were flat! I'm switching now!!!! At that time I bought a new branch of machinery, worked for seven months, now want to sell, but I do not know where the old equipment received

- Q:Semi automatic packing and full automata are used for packing and distinguishing

- Semi automatic strapping machines do not require very high packing straps. They can be used in general. However, if the belt is too thin, the machine will wear much more, and parts of the parts may be replaced more frequently.Automatic packaging machine on the tape requirements are very high, the general ordinary packing belt is automatic can not beat, it is best to use a good band, the toughness of the belt is stronger, hardness is enough! The easy way is to take the head of the tape and stretch it. Try to stretch the strap as much as possible, to see if the tape is stiff and straight enough!

- Q:Why is plastic strapping broken?

- Plastic steel belt itself is elastic, broken tension standard 1608 plastic tape, breaking tension to close to 200kg.

- Q:What is the reason why the packing belt breaks easily?

- When packaging, if packaged with fracture, may be packing machine pulling force is too strong, can adjust the tension knob. If packaged with other normal use, may be a problem with the packing quality, bear tensile strength not too big, you can consider replacing the packing belt

- Q:Profit and Prospect of baling belt

- How to provide solutions to the market, become a breakthrough in the packaging industry?. That customer oriented and not to study the market will be unable to keep up with the needs of customers has been phased out, new sales formats need to be packaged to solve the new program.

- Q:Production process of PP packing belt

- Easy to stretch orientation to obtain high quality products. Then, the tensile and tensile purposes are to increase the longitudinal strength of the strap and reduce the elongation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polyester Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products