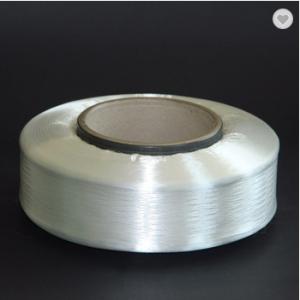

Polyester Filament Yarn FDY SD Raw white

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info

Product name: FDY 1000D HIGH TENACITY INDUSTRIAL YARN

Material: 100% Polyester

Pattern: dope-dyeing

Yarn Type: FDY, Filament

Feature: Eco-Friendly, Recycled, High Tenacity

Use: Weaving, Knitting, Sewing , Weaving , Knitting

Twist: S/Z TWIST

Evenness: EVEN

Color: white , black

MOQ: 30 KGS

Quality: AA Grade

Package: Pallet

Package Type: 4bobbins/carton, 10KG/bobbin, 40KG/cartons, 12 tons/20gp, 24 tons/40HQ

Certification: GRS, TC, OEKO

Keywords: Recycled FDY yarn, R-pet yarn, Eco-Friendly yarn

Specification: 50D/24F~144F, 75D/36F~144F, 100D/36F~288F, 150D/36F~288F, 200D/72F~288F, 300D/72F~576F, 450D/144F, 450D/192F, 600D/144F, 600D/192F or as per customers customized, single or double

Application: THE APPLICATION OF HIGH TENACTIY YARN IS FOR SLING, CONVEYOR BELT, GEOGRID, GEOTEXTILE, YARN-COATING, ROPE, SEWING THREAD, WEBBING, TIE DOWN, NETTING, HOSES, TEXTILENE, ETC.

Payment: T/T, LC

Production Facilities of FDY Yarn

We have the most advanced production system DSC. The whole production process is conducted and supervised by the operating platform. Meanwhile, there are 10 TMT fully automatic winding machine and Robot packaging system which highly improves the production efficiency and avoids manual mistakes.

Production Capacity of FDY Yarn

The production capacity is 200,000 TONS per year for now and it will be of 500,000 per year after the erection of the second production line.

Application and suggestion:

1. The adhesive of two layers of sports shoe Upper material —FDY 50D/75D

2. Soft curtain, Zebra curtain, Roman curtain—FDY 75D/150D

3. Vertical blinds—FDY 250D

4. Filter net for air condition—FDY 30D/50D/75D/150D

5. Electromagnetic wire: PET-Glass fiber blended fiber—FDY 50D/75D

6. Garment lining cloth for suit, tie, hat, etc. —FDY 150D/50D/420D

7. Warp knitting fabric such as: Stiff mesh fabric, medical/food filter net, inner car decoration.

8. Top-grade eco-friendly filter material

9. Other applications: protective gloves, dust gauze, top-grade window screen, invisible screen, etc.

- Q:How does the textile shake the knot?

- 2, the right hand will be the yarn frame on the twisted yarn head to find, put the right hand thumb food fingers pinch the yarn, the two yarn into a cross shape. 3, the right hand thumb fingers pinch the top of the hammer head, along the left hand around the thumb, and then pressure in the cheese under the yarn head.

- Q:What are the types of textile yarns?

- Raw yarn (unprocessed): UDY (no extension) POY (semi-extended) FOY (full extension), processing wire, spinning, packing yarn, yarn number of shares: single strand

- Q:What is the reason why the yarn is spinning

- The insurance yarn is woven out of cloth on the edge of 0.5 to 1 cm of the lock side, is to prevent the yarn spread out the yarn, the insurance yarn is more important than the weaving yarn

- Q:Men's sweaters with what yarn?

- Men's (middle-aged) autumn and winter sweater yarn: low-end: the proposed use of expanded polyester yarn, yarn yarn prices generally in 26 yuan / Kg

- Q:Why in general the yarn in the woven fabric strength coefficient of use greater than 1

- (2) combed yarn: cotton yarn is combed by the spinning system spinning yarn. Combing yarn selection of high-quality raw materials, yarn in the fiber straight parallel, knot less, good gloss, dry, high strength, this type of cotton yarn used for weaving high-grade fabric

- Q:Forming Principle of Yarn of Textile Industry

- But the formation of the mechanism is the same, are controlled by the ladle up and down, spinning the speed of Rao Rao is generally the same.

- Q:What does JC40S cotton yarn mean?

- (2) combed yarn: cotton fiber is combed spinning system spinning yarn. Combine yarn selection of high quality raw materials, the use of cotton yarn, Yarn in the fiber straight parallel, less knot, good gloss, dry strips, high strength, this type of cotton yarn used for weaving high-grade fabric.

- Q:40s / 2 What does it mean, is this yarn 40 or 80?

- 21S / 1 x 40S / 2 means: 100% cotton fabric is 21S (count) / 1 (single stock) x 40S (count) / 2 (double

- Q:Cotton yarn from the process and use is how to divide

- Carding spinning process: with cotton → open cotton → carding → parallel → roving → yarn → down tube (sub-artificial winder and automatic winding two) → finished product inspection.

- Q:What is the knitting yarn and the woven gauze?

- Woven yarn requirements: strong high, less neps. Knitted yarns are relatively strong without weaving yarns, but the details are demanding and the twist is also free of woven yarn

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polyester Filament Yarn FDY SD Raw white

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products