Polyester Coating Aluminium Coils for Outer Wall Curtain

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

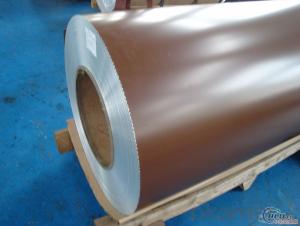

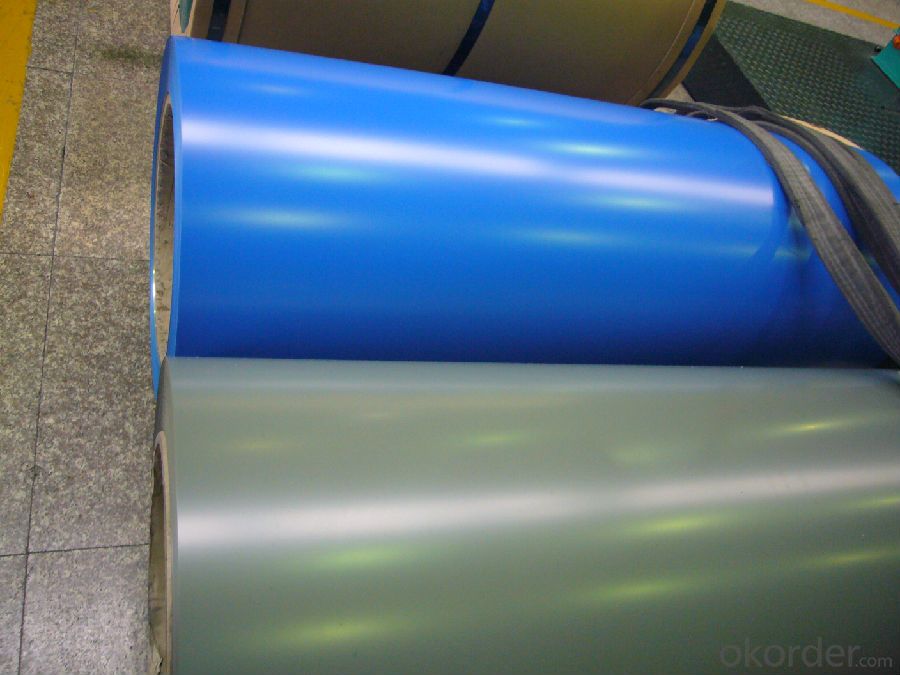

1.Structure of Polyester Coating Aluminium Coils for Outer Wall Curtain

Polyester Coating Aluminium Coils for Outer Wall Curtain are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Polyester Coating Aluminium Coils for Outer Wall Curtain

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Coating Thickness |

| AA1050 | H14 | 0.2-3MM | 1000-1800MM | 20-25 MICRONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q:why does 10% sulfuric acid not react with aluminum sheet?

- 10% sulfuric acid has a high concentration and will be passivated and formulate a layer of oxide film after reacting with aluminum,and the reaction will stop after seperating sulfuric acid and aluminum. there is a layer of Al2O3 oxide film on the surface of aluminum, so it's hard for sulfuric acid to break the oxide film and react with aluminum.

- Q:What are the electrical conductivity properties of aluminum sheets?

- Aluminum sheets are equipped with exceptional electrical conductivity characteristics. With its low electrical resistance, aluminum finds extensive usage in diverse electrical applications. It boasts a high conductivity rating, marginally lower than that of copper, rendering it an effective electricity conductor. This attribute enables aluminum sheets to efficiently transmit electrical current with minimal energy wastage. Consequently, aluminum is extensively employed in power transmission lines, electrical wiring, and electrical connectors. Moreover, aluminum's conductivity renders it suitable for applications requiring heat dissipation, such as heat sinks in electronic devices. In general, aluminum sheets are renowned for their favorable electrical conductivity, making them a preferred choice in numerous electrical and electronic applications.

- Q:What is the main influence of the spacing?What are the main effects of spacing?

- Thermal explosion is related to a lot of factors. As to how much impact the lining board has on the thermal explosion, it's really impossible to speak of it. I think it has very little influence

- Q:How do aluminum sheets perform in terms of water resistance?

- Aluminum sheets generally exhibit excellent water resistance due to their natural oxide layer, which forms a protective barrier against corrosion. This oxide layer prevents water from penetrating the surface, making aluminum sheets highly resistant to water damage and rusting.

- Q:Can aluminum sheet be used for food packaging?

- Yes, aluminum sheet can be used for food packaging.

- Q:Can aluminum sheets be used for reflective insulation?

- Indeed, reflective insulation can make use of aluminum sheets. With their high reflectivity and impressive thermal conductivity, aluminum proves to be an exceptional option for effectively reflecting heat and minimizing heat transfer. By employing aluminum sheets as insulation, heat can be effectively redirected away from the surface, effectively preventing its entry or escape from the desired space. This proves to be advantageous in maintaining a cozy temperature indoors or safeguarding delicate equipment against extreme temperatures. Moreover, the lightweight nature and ease of installation of aluminum sheets further contribute to their popularity in reflective insulation applications.

- Q:Can aluminum sheet be used for chemical processing?

- Yes, aluminum sheet can be used for chemical processing. Aluminum is a versatile and corrosion-resistant material that is widely used in various industries including chemical processing. It is known for its excellent resistance to many chemicals, such as acids, alkalis, and salts. This makes it suitable for applications where exposure to corrosive substances is common. Additionally, aluminum is lightweight, durable, and has good thermal conductivity, making it an ideal choice for heat transfer and energy-efficient processes in chemical industries. However, it is important to consider the specific chemical environment and consult with experts to ensure the compatibility of aluminum with the particular chemicals and conditions involved in the process.

- Q:What is the specific heat capacity of aluminum sheets?

- The approximate specific heat capacity for aluminum sheets is 0.897 J/g°C, indicating that to increase the temperature of 1 gram of aluminum by 1 degree Celsius, 0.897 joules of energy is needed. While the specific heat capacity may slightly differ based on the aluminum sheet's purity and specific alloy, this value serves as a fairly accurate approximation for the majority of commonly used aluminum sheets.

- Q:Can aluminum sheets be anodized?

- Yes, aluminum sheets can be anodized. Anodizing is an electrochemical process that creates a durable, corrosion-resistant layer on the surface of aluminum. This process can be applied to aluminum sheets to enhance their appearance, increase their resistance to wear and tear, and improve their overall performance.

- Q:Does aluminum sheet require special handling during transportation?

- Transporting aluminum sheets requires special handling due to their lightweight nature and susceptibility to damage if mishandled. To prevent scratching, bending, or denting, it is necessary to take specific precautions. Packaging and securing the sheets in a manner that restricts movement and offers sufficient protection against impacts is crucial. Furthermore, it is important to transport aluminum sheets separately from heavy objects or materials to avoid potential damage caused by their weight. In conclusion, ensuring the safe transportation of aluminum sheets necessitates giving them special care and attention.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polyester Coating Aluminium Coils for Outer Wall Curtain

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords