Polyester Coated Aluminum Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Polyester Coated Aluminum Coil for Construction Description:

Color coated aluminum coil is aluminum coil after cleaning, coating, and baking. Surface of aluminum coil can be painted to any color. Dong Chuan color-coated aluminum coil and aluminum sheet coils mainly come from Southwest Aluminum, Nanping, Chinalco, Ruimin, etc. which are the best raw materials suppliers domestically. Our coating paints are mainly from American PPG and Swedish Becker.

2.Main Features of Polyester Coated Aluminum Coil for Construction:

Good mechanical properties.

Easy processing, wearability.

Corrosion resistance

Resistance to oxidation.

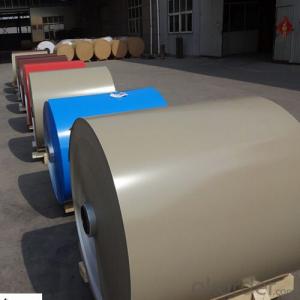

3. Polyester Coated Aluminum Coil for Construction Images:

4. Polyester Coated Aluminum Coil for Construction Specification:

Item | Color Coated Aluminium coil,Aluminium coil,Aluminium alloy coil, |

Standard | GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc |

Material | 1060,1050,1070,1100,a1100P,3003,3005,5052,5652,5154,5254,5454,5083,5754, 5086,5056,5456,2A12,2024,2014,6061,6062,6063,6082,7003,7004,7075,8010,8020,etc |

Thickness | 0.1-200mm |

Width | 10-2600mm |

Length | 1-12m,or as required |

Temper | 0-H112,T3-T8,T351-T851 |

Surface | mill,bright,polished,hair line,brush,sand blast,checkered,embossed,etching,etc |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q:I've heard certain eyeliners contain lead and that it's a harmful (cancerous) ingredient. I use Urban Decay's 24/7 eyeliner and on the box it says it contains aluminum powder. Is that another word for lead? If not, is aluminum powder harmful too? Thanks!

- Nope - not lead. Aluminum is one of the most common substances in the earths crust. Shouldn't hurt you. And actually fancy ladies covered their faces with white lead for a LONG time (Queen Elizabeth I white face was from white lead) - and these people didn't die even though they had quite a poisonous stuff on their skin.

- Q:What is the cost of aluminum sheets?

- The cost of aluminum sheets can vary depending on factors such as size, thickness, and quantity. It is best to check with suppliers or retailers for current pricing information.

- Q:What kind of paint would you like to paint on the aluminum plate?

- Nitro paint, polyester paint can be mainly your base, you should use atomic ash treatment before you can use, otherwise it will peel off

- Q:I am doing a project on Aluminum it has 13 protons just to make sure everyones on the same page. How much of it is left or exsits? Also how does it behave?

- Aluminium is one of the most abundant Element on earth, ranking 3rd in the crust, second only to oxygen and silicon. And it is eminently recyclable. However, many minerals containing aluminium are not economically exploitable.

- Q:Are aluminum sheets suitable for electrical bus bars?

- Yes, aluminum sheets are suitable for electrical bus bars. Aluminum is a lightweight and cost-effective material that exhibits good electrical conductivity. It is commonly used in various electrical applications, including bus bars, due to its ability to efficiently carry high electrical currents while dissipating heat effectively.

- Q:What is aluminium plate for?

- Two outdoor and indoor, outdoor curtain wall decoration, indoor ceiling (such as aluminum pinch plate, aluminum grille, aluminum hanging tablets, etc.), color diversity, but also can be made imitation wood grain, imitation marble and other colors, widely used

- Q:Can 101 aluminum sheets be anodized for medical equipment applications?

- Yes, 101 aluminum sheets can be anodized for medical equipment applications. Anodizing is a process that enhances the corrosion resistance and durability of aluminum, making it suitable for various industries, including medical equipment.

- Q:What are the common aluminum sheets and the best ones?

- Look, what's your use for it?. Aluminum alloy is divided into 1000 series and 9000 series, each series has the characteristics and uses of each series. The most commonly seen aluminum plate is 1060 (pure aluminum), 2024, 5052, 6061, 6063, 7075, 6083, 5082 aluminum alloy plate. The best should be imported 7000 series, but also depends on your use to say.

- Q:Are aluminum sheets suitable for mold making?

- No, aluminum sheets are not suitable for mold making as they lack the flexibility and malleability required for creating intricate shapes and designs. Mold making typically requires materials like silicone or rubber that can capture fine details and easily release the molded object.

- Q:Are aluminum sheets resistant to abrasion?

- Indeed, aluminum sheets exhibit a general resistance to abrasion. Renowned for its sturdy nature and robustness, aluminum proves impervious to scratches or harm induced by abrasion. Nevertheless, the degree of resistance may fluctuate contingent upon the particular alloy and thickness of the aluminum sheet. Sheets boasting greater thickness and higher alloy content typically offer superior protection against abrasion. Furthermore, the surface finish of the aluminum sheet can also influence its resistance to abrasion. All things considered, aluminum sheets present a dependable option for enduring abrasion in a myriad of applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polyester Coated Aluminum Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords