Polycrystalline Solar Cell High Quality 16.80-18.00 Effy

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Solar Cells:

solar cells, when struck by photons of light from the sun, generates an electrical current which can then be used to power DC or AC electrical loads.

A solar cell is made of silicon. Computer chips are made of this same material. Basically, when light strikes the surface of a solar cell some of it is absorbed into the silicon. This light energy bumps the electrons loose and causes energy to flow

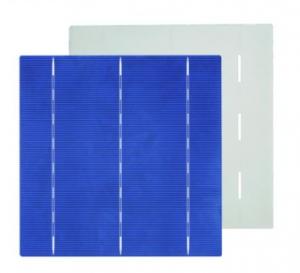

Solar cells is made by solar wafer, it has three categories of solar cell right now, monocrystalline polycrystalline and thin film,These cells are entirely based around the concept of PN junction, which is the critical part of solar module, it is the part that can convert the light energy into electricity, the thickness is from 180um to 200um, with even busbars to conduct electricity, textured cell can decrease diffuse reflection; they are often electrically connected and encapsulated as a module. Photovoltaic modules often have a sheet of glass on the front (sun up) side, allowing light to pass while protecting semiconductor wafers from abrasion and impact due to wind-driven debris, rain, hail, etc. Solar cells are also usually connected in series in modules, creating an additive voltage. Connecting cells in parallel will yield a higher current;With high quality and stable quality. Our Cells can greatly improve the performance of Solar Modules.

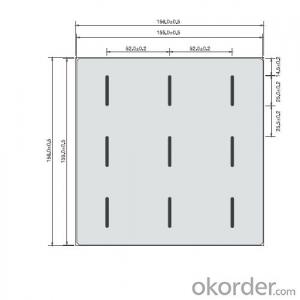

Specifications

Efficiency(%) | 18.00 | 17.80 | 17.60 | 17.40 | 17.20 | 16.80 |

Pmpp(W) | 4.33 | 4.29 | 4.24 | 4.19 | 4.14 | 4.09 |

Umpp(V) | 0.530 | 0.527 | 0.524 | 0.521 | 0.518 | 0.516 |

Impp(A) | 8.159 | 8.126 | 8.081 | 8.035 | 7.990 | 7.938 |

Uoc(V) | 0.633 | 0.631 | 0.628 | 0.625 | 0.623 | 0.620 |

Isc(A) | 8.709 | 8.677 | 8.629 | 8.578 | 8.531 | 8.478 |

Solar Cells Advantage:

• High efficiency and stable performance in photovoltaic conversion.

• Advanced diffusion technique ensuring the homogeneity of energy conversion efficiency of the cell.

• Advanced PECVD film forming, providing a dark blue silicon nitride anti-reflection film of homogenous color and attractive appearance.

• High quality metal paste for back surface and electrode, ensuring good conductivity, high pulling strength and ease of soldering.

• High precision patterning using screen printing, ensuring accurate busbar location for ease with automatic soldering a laser cutting.

Features:

1. High conversion efficiencies resulting in superior power output performance

2. Outstanding power output even in low light or high temperature conditions

3. Optimized design for ease of soldering and lamination

4. Long-term stability, reliability and performance

5. Low breakage rate

6. Color uniformity

FAQ

We have organized several common questions for our clients,may help you sincerely:

①What price for each watt?

It depends on the efficiency of the solar cell, quantity, delivery date and payment terms.

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

③Can you provide the peripheral products of the solar panels, such as the battery, controller, and inverter? If so, can you tell me how do they match each other?

Yes, we can, we have two companies for solar region, one is CNBM International, the other is CNBM engineering Co.

We can provide you not only the solar module but also the off grid solar system, we can also provide you service with on grid plant.

④What is your warranty of solar cell?

Our product can promise lower than 0.3% open box crack, we support claim after opening the box if it has crackm color difference or sth, the buyer should give pictures immediately, we can not accept the claim after the solar cell has assembled to solar panel.

• Timeliness of delivery

• ⑤How do you pack your products?

We have rich experience on how to pack the solar cell to make sure the safety on shipment, we could use wooden box or pallet as buyer's preference.

How to Make Solar Cell in Home

Solar cells have a huge usage in home. If you want to get a solar cell at home, you can light up your little things like a clock, radio, etc. And here some steps to make solar cells . First, take a copper sheet and cut it into equal parts. After cutting, you have 2 pieces of the same size. Step2: Heat up one piece of copper sheet completely using a burner or gas stove. Heat up 20 to 30 minutes. Then place it undisturbed to cool down. Step3: Attach a piece of copper wire to it. Clear that place where you will attach copper wire to it. Step 4: Take another piece of copper sheet and attach it to another piece of copper wire. Step5: Take a plastic bottle and cut it half. In the bottom part of bottle make a solution of hot water and salt. Step6: Paste burned copper sheet in the bottle. Only copper sheet touched with water not copper wire. Step7: In opposite direction paste another piece of copper sheet. Step8: Now your solar cell is ready to be attached to anything to the wire which is attached to copper sheets.

How to Build your own Solar Cell

Step 1: Stain the Titanium Dioxide with the Natural Dye: Stain the white side of a glass plate which has been coated with titanium dioxide (TiO2). This glass has been previously coated with a transparent conductive layer (SnO2), as well as a porous TiO2 film. Crush fresh blackberries, raspberries, pomegranate seeds, or red Hibiscus tea in a tablespoon of water. Soak the film for 5 minutes in this liquid to stain the film to a deep red-purple color. If both sides of the film are not uniformly stained, then put it back in the juice for 5 more minutes. Wash the film in ethanol and gently blot it dry with a tissue.

Step 2: Coat the Counter Electrode: The solar cell needs both a positive and a negative plate to function. The positive electrode is called the counter electrode and is created from a "conductive" SnO2 coated glass plate. A Volt - Ohm meter can be used to check which side of the glass is conductive. When scratched with a finger nail, it is the rough side. The "non-conductive" side is marked with a "+." Use a pencil lead to apply a thin graphite (catalytic carbon) layer to the conductive side of plate's surface.

Steps 3: Add the Electrolyte and Assemble the Finished Solar Cell: The Iodide solution serves as the electrolyte in the solar cell to complete the circuit and regenerate the dye. Place the stained plate on the table so that the film side is up and place one or two drops of the iodide/iodine electrolyte solution on the stained portion of the film. Then place the counter electrode on top of the stained film so that the conductive side of the counter electrode is on top of the film. Offset the glass plates so that the edges of each plate are exposed. These will serve as the contact points for the negative and positive electrodes so that you can extract electricity and test your cell. Use the two clips to hold the two electrodes together at the corner of the plates. The output is approximately 0.43 V and 1 MA /cm2 when the cell is illuminated in full sun through the TiO2 side.

- Q:How do solar cells affect the aesthetics of a building?

- Solar cells can have a significant impact on the aesthetics of a building. While their installation may alter the appearance of the structure, advancements in solar technology have led to more aesthetically pleasing designs. With options like integrated solar panels or solar shingles that blend seamlessly into the building's design, solar cells can enhance the overall aesthetics and even contribute to a more modern and sustainable look. Additionally, the sight of solar panels on a building can signal an environmentally conscious approach, which many people find visually appealing.

- Q:What is the role of monitoring systems in solar cell systems?

- The role of monitoring systems in solar cell systems is to continuously monitor and analyze the performance and efficiency of the solar panels. It allows for real-time tracking of the energy production, detecting any malfunctions or abnormalities, and identifying potential issues that may affect the overall system performance. This data helps in optimizing the efficiency of the solar cell system, ensuring maximum energy generation, and enabling timely maintenance and repairs. Monitoring systems also provide valuable insights for system optimization, energy consumption analysis, and performance evaluation.

- Q:Can solar cells be used in mobile devices?

- Yes, solar cells can be used in mobile devices. In fact, many manufacturers are now incorporating solar panels into smartphones, tablets, and other portable gadgets to harness solar energy and provide an alternative source of power.

- Q:What is the impact of shading on solar cell performance?

- Shading has a significant impact on solar cell performance as it reduces the amount of sunlight reaching the cells, leading to decreased energy production. Even partial shading, such as from trees or nearby buildings, can result in substantial losses in power output. This is because solar cells are connected in series, and when one cell is shaded, it acts as a barrier to the current flow, affecting the performance of the entire system. To mitigate this issue, shading analysis and proper system design, like using bypass diodes, can help minimize the impact of shading on solar cell performance.

- Q:Can solar cells be combined with energy storage systems?

- Yes, solar cells can be combined with energy storage systems. The integration of solar cells and energy storage systems allows for the capture and storage of excess energy generated by the solar cells during periods of high production. This stored energy can then be utilized during times when solar production is low or when there is a higher demand for electricity. This combination enables a more efficient and reliable renewable energy solution.

- Q:Can solar cells be used in greenhouses or agricultural facilities?

- Yes, solar cells can be used in greenhouses or agricultural facilities. By harnessing the power of the sun, solar cells can generate electricity to power various operations within these facilities, such as lighting, heating, ventilation, and irrigation systems. Additionally, solar cells can help reduce energy costs and carbon emissions, making them a sustainable and eco-friendly choice for agricultural practices.

- Q:Can solar cells be used in aviation or aerospace applications?

- Yes, solar cells can be used in aviation or aerospace applications. Solar cells are commonly used in satellites to generate electricity from sunlight. They can also be used in unmanned aerial vehicles (UAVs) or drones to power their systems and extend their flight time. Additionally, some experimental aircraft have integrated solar panels to supplement their power needs.

- Q:Is the Solar Power Photovoltaic Cells the same as PV cells modules?

- According to the size and scale of the photovoltaic power station, the PV modules can be composed of various sizes and different arrays.

- Q:Can solar cells be used on wearable technology?

- Yes, solar cells can be used on wearable technology. Advances in technology have made it possible to integrate solar cells into small and flexible materials, making them suitable for use in wearable devices. These solar cells can generate and store energy from sunlight, allowing wearable technology to become self-sustaining and reducing the need for frequent recharging or battery replacements.

- Q:Can solar cells be used for powering remote sensors?

- Yes, solar cells can be used for powering remote sensors. Solar cells convert sunlight into electricity, making them a reliable and sustainable source of power for remote applications. They are commonly used to provide continuous power to sensors in remote locations, where access to the electrical grid may be limited or non-existent.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polycrystalline Solar Cell High Quality 16.80-18.00 Effy

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords