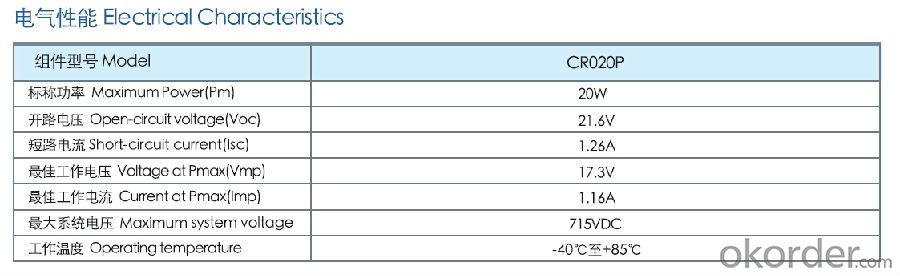

Polycrystalline silicon solar panel(CR020P)

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

High-efficient solar cells

High transmissivity low-iron toughened glass

Anodized aluminum frame

Water resistant junction box

Design to meet unique demand of customer

25 year poweroutput warranty

In the series, the products description is as follows:

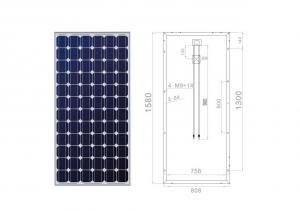

cell dimension:156mm*156mm

number of celles and connections: 6 (4*9)

panel dimension: 536*353*30(mm)

per weight: 2.6 KG

junction box type: PV-GZX0502

cable and asymmetrical lengths: NANYANG(1.5mm2), 300mm(-)and 300mm(+)

connection: MC4

- Q:Can solar panels be installed on a balcony or terrace?

- Yes, solar panels can be installed on a balcony or terrace as long as there is sufficient sunlight exposure and structural support in place to hold the panels securely.

- Q:Can solar panels increase the value of my property?

- Yes, solar panels can increase the value of your property. Studies have shown that properties equipped with solar panels have higher resale values compared to those without. Solar panels offer energy savings, environmental benefits, and potential tax incentives, making them an attractive feature for potential buyers. Additionally, as renewable energy becomes increasingly popular, properties with solar panels are likely to be in higher demand, further boosting their value.

- Q:What maintenance is required for solar panels?

- Regular maintenance for solar panels includes cleaning the surface to remove dirt and debris, inspecting for any damage or loose connections, and monitoring the system's performance to ensure optimal efficiency.

- Q:Can solar panels be used to power a water pump?

- Yes, solar panels can be used to power a water pump. Solar panels generate electricity from sunlight, which can be used to power various devices and appliances, including water pumps. This allows for a sustainable and environmentally friendly way of pumping water, especially in remote or off-grid locations where access to electricity may be limited.

- Q:Can solar panels be installed on streetlights?

- Yes, solar panels can be installed on streetlights. They provide a sustainable and cost-effective solution by harnessing the sun's energy to power streetlights, reducing the dependence on traditional electricity sources and lowering overall energy costs. Additionally, this renewable energy option helps to reduce carbon emissions and promote environmental sustainability.

- Q:Are there any restrictions on installing solar panels in certain areas?

- Yes, there can be restrictions on installing solar panels in certain areas. These restrictions can vary depending on local regulations, zoning laws, homeowners' association rules, and building codes. Some areas may have height restrictions, setback requirements, or aesthetic guidelines that limit the placement or visibility of solar panels. Additionally, historic districts or areas with protected landscapes may have stricter regulations. It is important to check with local authorities and consult any relevant guidelines or permits before installing solar panels in a specific area.

- Q:how efficient are flexible solar panels?

- One I got about 3 years ago is about 50% as efficient as a glass panel I got about 0 years ago. Not exactly a scientific study, I know.

- Q:My mom's house has some solar power panels on the top of her house but they are not connected to anything. They don't even have wires or anything like that. Does anyone know how to connect and make solar panels work? Thank You

- FIrst get an electrician...lol shouldnt cost too much if all the hardware is there , but depending on how many panels there are and what can... would tell you if the energy output would be worth the effort. plus one reason they could be unplugged is because they are bad . But you can repanel a new house with moderate power for about 3-5 grand

- Q:We want make solar panel for our home use. but we have no any right idea how we can make it. we want to make it with cheap prices.we also want to know the proper size of solar panel.where we can take help about making a solar panel

- Create okorder

- Q:I am planning to buy some solar panels for my cabin and i want to be able to store the electricity. what kind of batteries should i get? i will be running simple things like a tv and radio. where can i buy these batteries? where should i look for the best batteries?

- If you will be storing them outdoors, you can use auto batteries. Indoors, use sealed marine batteries. Number and size depends on your needs. You will need a charge controller between the solar panels and the batteries to get the maximum power out of the array and to avoid damage to the batteries. And you will need an inverter to convert the 2 or 24 volts to 20 or 240 VAC. One large lead acid battery will supply about 000 watt-hours of energy, enough for 200 watts for 5 hours. You have to look at your loads and decide on how many batteries you need. Frequently it is cheaper to buy new appliances that use less power, as that power difference can save a lot of money in batteries, inverter, charge controller and solar panels. But it sounds like a few thousand watt-hours will be enough, or 2 large batteries. The real limiting factor is how much money you want to spend for the solar panels themselves. .

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polycrystalline silicon solar panel(CR020P)

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords