Polycrystalline Silicon Solar Panel(250W)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 watt

- Supply Capability:

- 100000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure

Mono-Crystalline solar panel, Poly 156 cell, 60pcs.

Power range 230W-260W.

Quality and Safety

1. Rigorous quality control meets the highest international standards.

2. High-transmissivity low-iron tempered glass, strong aluminium frame.

3. Using UV-resistant silicon.

4. IS09001/14001/CE/TUV/UL

Feature

Warranties

1. 10 years limited product warranty

2. 15 years at 90% of the minimal rated power output

3. 25 years at 80% of the minimal rated power output

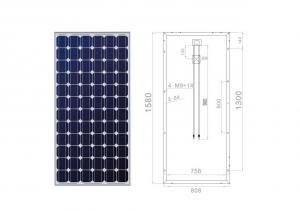

Images

Specification

Technical date

ITEM NO.: | Poly 156*156 cell ,60pcs . Power range from 230Wp-260Wp | ||||||

Maximum Power(W) | 230 | 235 | 240 | 245 | 250 | 255 | 260 |

Optimum Power Voltage(Vmp) | 29.4 | 29.5 | 29.7 | 30.1 | 30.3 | 30.5 | 30.7 |

Optimum Operatige Current(Imp) | 7.83 | 7.97 | 8.08 | 8.14 | 8.25 | 8.37 | 8.48 |

Open Circuit Voltage(Voc) | 36.7 | 36.8 | 36.9 | 37.1 | 37.3 | 37.5 | 37.7 |

Short Circuit Current(Isc) | 8.52 | 8.59 | 8.62 | 8.65 | 8.69 | 8.73 | 8.78 |

Solar Cell: | 156*156 Poly | ||||||

Number of Cell(pcs) | 6*10 | ||||||

Brand Name of Solar Cells | JA Cell, Bluesun Cell | ||||||

Size of Module(mm) | 1650*992*40/45/50 | ||||||

Cable & Connector Type | Pass the TUV Certificate | ||||||

Frame(Material Corners,etc.) | Aluminium-alloy | ||||||

Back sheet | TPT | ||||||

Weight Per Piece(KG) | 19.5KG | ||||||

FF (%) | 70-76% | ||||||

Junction Box Type | Pass the TUV Certificate | ||||||

Tolerance Wattage(e.g.+/-5%) | ±3%, or 0-3% | ||||||

Front Glass Thickness(mm) | 3.2 | ||||||

Temperature Coefficients of Isc(%) | +0.04 | ||||||

Temperature Coefficients of Voc(%) | -0.38 | ||||||

Temperature Coefficients of Pm(%) | -0.47 | ||||||

Temperature Coefficients of Im(%) | +0.04 | ||||||

Temperature Coefficients of Vm(%) | -0.38 | ||||||

Temperature Range | -40°C to +85°C | ||||||

Surface Maximum Load Capacity | 5400Pa | ||||||

Allowable Hail Load | 23m/s ,7.53g | ||||||

Bypass Diode Rating(A) | 12 | ||||||

Warranty | 90% of 10 years, 80% of 25 years. | ||||||

Standard Test Conditions | AM1.5 1000W/ 25 +/-2°C | ||||||

Packing | carton or pallet | ||||||

1*20' | 14 Pallets / 316pcs | ||||||

1*40'STD | 25 Pallets / 700pcs | ||||||

FAQ

1. Q: Are you a factory or trading company?

A: We are a factory.

2. Q: Where is your factory located? How can I visit there?

A: Our factory is located in Huzhou, Zhejiang, China, near Shanghai. You are warmly welcomed to visit us!

3. Q: How can I get some samples?

A: Please connect me for samples, and my phone number: +86 158 5821 3997.

4. Q: Can the price be cheaper?

A: Of course, you will be offered a good discount for big amount.

- Q:Hey i am going to build a scale model house and demonstrate how you would use solar panels to provide energy. I am thinking of buying some kit solar panels and wiring up some lights to show how they power the home. Also i might hook up a battery in the house to show how you can store the energy. I might also have a large battery hooked up outside the house to represent a power plant that could provide emergency power. Any ideas or comments would be great. Thanks

- Build okorder /

- Q:The first panel is located in New England, the second is placed in the Sahara desert, the third is on the Earth side of the moon, and the last is on the far side of the moon. Which panel would absorb the most sunlight over a year's time and why ? All the panels are place in optimal places where they would get the most light available.

- Well, as always, context is important. Sunlight is composed of a lot of different types and wavelengths of energy, and our atmosphere and magnetoshpere filter out a certain amount. If the question is actually which solar panel would produce the most energy (which I assume it is), we would have to look at how solar panels work. There are three different classes of solar panel function. Photovoltaic cells convert sunlight directly into electrical energy, but most systems are pretty low on efficiency. Solar cells can be used for generating heat, through boiling water or some other liquid frequently. And solar panels can be used to produce chemical reactions, breaking down solutions into ions, for example, and the breaking of the molecular bonds releases a certain amount of energy. So theoretically, the two sides of the moon get the same amount of solar energy, just at different times -- about 6 months of the year or so. If the solar panels were thermal energy panels, the ones on the Earth would do much better, because the moon is so much colder. The weather is the most convincing argument for comparing the Sahara and New England. New England is likely to be more cloudy and polluted than the Sahara. Since the Earth probably eclipses the moon a bit more often than the reverse, there may be a little more visible sunlight that gets to earthly solar panels, but the ones on the moon would get a greater proportion of the sunlight (more wavelengths, for example), so it would be close. The Earth eclipses only the near face of the moon, so that would give the far side of the moon a slight edge perhaps. I'd guess it would be the far-side lunar one, but too many variables to be sure.

- Q:How do solar panels perform in cloudy weather?

- Solar panels do generate electricity even in cloudy weather, although their efficiency is reduced compared to sunny days.

- Q:Can solar panels be used for powering a wastewater treatment plant?

- Yes, solar panels can be used for powering a wastewater treatment plant. Solar energy can be harnessed and converted into electricity, which can then be used to power the various components and processes involved in wastewater treatment. This renewable energy source helps reduce reliance on non-renewable fuels, lowers operational costs, and minimizes the environmental impact of the treatment plant.

- Q:Can someone tell me the average savings you get PER solar panel installed? I do not have the money to invest in a bunch of them at once, so I am forced to buy one at a time, when I have the money. So how much can I expect to save after I buy the first one?

- No matter what or how you do it it is best to get off coal and nukes. So it cost a little bit of money you are buying 30 years of electric. How much will you spend adding in cost of living increases over the next 30 years? Solar really is pretty cheap if you take the time to do the long term math. If you use your cost at to days rates it does seem like a lot. But if you do the math like in real life with 3.5% compounded cost of living increases per year and 6.5% fuel increases per year. Well, you pay a lot more renting power. One other thing to think about and Al Gore keeps pointing it out is, Will your off spring be alive in 50 years from now if you don't buy the solar panel? Kind of like not going to the doctor because you can't afford the bill. Well I would rather owe a bill to a doctor that I will have trouble paying then not be alive at all to try. If you don't have the money to jump in and go full blown Green you should buy a starter system. You can get a system that can be expanded to 3000 watts (enough to power an energy efficient home). Would cost you about $8000 USD to get started and then you could add three solar modules at a time till you get it up to the 3000 watt max. And even have backup power. Or you could just buy a 000 watt system for about the same price and just add 3 of them over the years. There are many ways to get started. The deal is everyone needs to get started even if it is a small system. If all 50 million homes in the USA would install a small 000 watt system with 4 hours of sun light a day. We would provide (000 watts times 4 hours times 365 days times 50 million homes) 29,000,000,000,000 watts not from coal or nuke plants per year. I wonder if that would help?

- Q:Where can I buy solar panels other than online in Charlotte, NC?

- You need to be more specific about what type of solar panel. ) PhotoVoltaic (produces electricity) 2) Fluid (Glycol) (heats water or air using a heat exchange tank) 3) Fluid (Water) for pool water heating

- Q:Can solar panels be installed on water treatment plants or utilities?

- Yes, solar panels can be installed on water treatment plants or utilities. In fact, many water treatment plants and utilities are increasingly adopting solar energy systems to reduce their reliance on traditional energy sources and lower their carbon footprint. Solar panels can be installed on the roofs of these facilities or on nearby open spaces to generate clean and renewable electricity to power their operations.

- Q:Can solar panels be installed on outdoor lighting fixtures?

- Yes, solar panels can be installed on outdoor lighting fixtures. In fact, many outdoor lighting fixtures are specifically designed to incorporate solar panels for sustainable and energy-efficient lighting solutions.

- Q:Can solar panels be used for powering a water treatment plant?

- Yes, solar panels can be used to power a water treatment plant. Solar energy can be harnessed to generate electricity, which can then be used to power the various processes involved in treating and purifying water. This renewable energy source provides a sustainable and environmentally friendly solution for powering water treatment plants.

- Q:How could I find out what the amp output of a solar panel? Specifically, I want to know how many milliamps can the solar panel on a Casio fx-260 put out?

- You need full sunshine from the sun, or a lamp that will give a light spectrum similar to the sun, a volt meter, Milli-amp meter, and a variable resistor of 0 to 000 ohms. The voltmeter test leads go across the solar cell leads. The amp meter leads will be in series with the solar cell. Let's say, positive lead of the solar cell to the the positive lead of the amp meter, the negative lead of the amp meter to one terminal of the variable resistor, and the wiper terminal of the variable resistor to the negative lead of the solar cell. Slowly decrease the value of the resistor until the voltage from the solar cell just begins to drop. Take note of the amp meter reading. This is about the high end range of the solar cell. You might want to begin with a micro-amp meter for the current meter.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polycrystalline Silicon Solar Panel(250W)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 watt

- Supply Capability:

- 100000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords