Polycrystalline Mullite Fire Blanket for Glass Kiln Made In China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

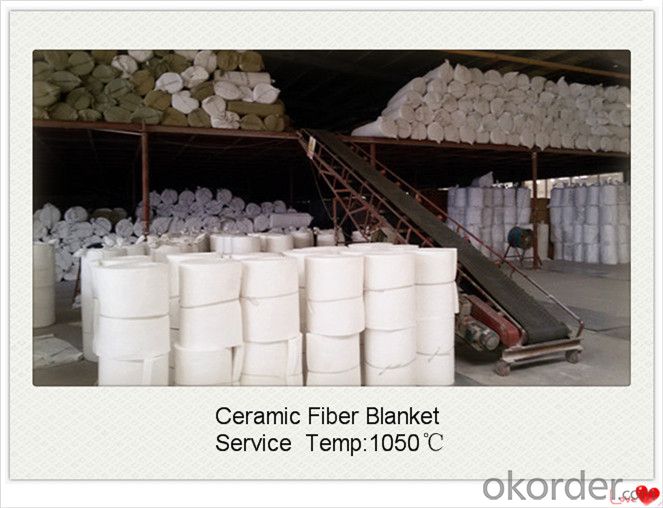

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polycrystalline Mullite Fire Blanket for Glass Kiln Made In China

Ceramic Fibre Blanket Discription

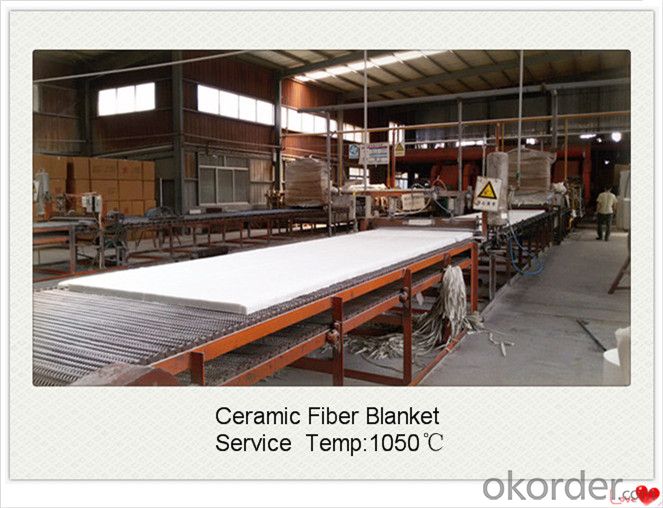

Ceramic fiber product is made from high quality Gao-ling clay, high purity alumina and silica oxides by spun or blown process. It is asbestos free. No chemical binder is added. Double-side needling provides blanket with great tensile or handing strength for easy installation.

There are four kinds of ceramic fiber products according to the temperature and chemical content. They are STD(1260℃),HP(1260℃),HA(1350℃, high alumina),HZ(1430℃,contain ZrO2).

1) For the blanket, the bulk density will be 64kg/m3, 96 kg/m3, 128 kg/m3, 160 kg/m3.

2) For the paper, the bulk density will be 160-220 kg/m3.

3) For the board, the bulk density will be 240-400kg/m3.

Ceramic fiber blanket, board,cloth and textiles are made from high quality clay, high purity alumina and silica oxides by spun or blown process.

Ceramic fibre blanket, board and cloth have a range of products:ordinary type,standard form,high-purity type, high-alumina type and containing zirconium type.Different types of products used different materials. performance of ceramic fibre insulation blanket also has difference,and they are suitable for different workong temperatures.

Ceramic fibre blanket, board and cloth can be used after optional cutting .When ceramic fibre insulation blanket storage should be paid attention to moistureproof.The high-alumina type and containing zirconium type products can be directly used as furnace lining .And using high-temperature refractory adhesive when stick.

Packaging & Delivery

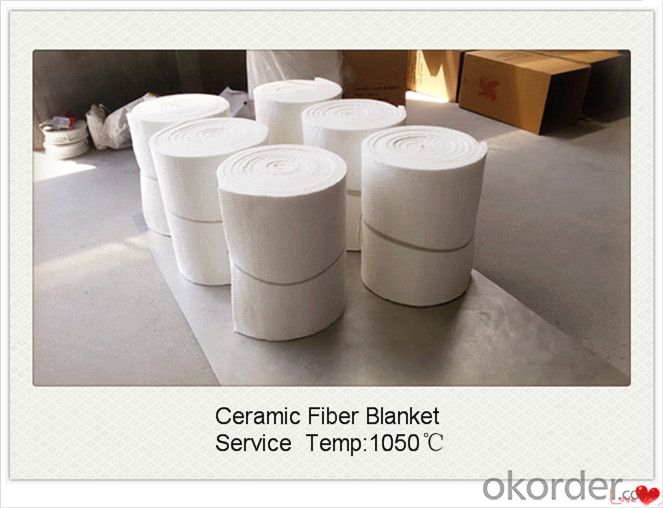

Each Roll/Case:12.5*610*14400mm, 25*610*7200mm, 50*610*3600mm

Characteristics of Ceramic Fibre Blanket

1)Low thermal conductivity

2)High tensile strength

3)Resilient to thermal shock

4)Corrosion resistance

5)High-purity type

6)High-temperature refractory

7)Al Content (%): 32-55

8)Type: 1260℃ STD/HP, 1350℃ HA, 1430℃ HZ

9)Density: 64-160kg/m3

10)Size: 12.5×610×14400mm, 25×610×7200mm, 50×610×3600mm

Applications of Ceramic Fibre Blanket

1.Industrial furnace, heating devices, high temperature pipe

2.High building fireproof ,sound-absorbing and thermal insulation material

3.Thermal insulation material for the electricity boilers, gas turbine and nuclear power.

4.Wall linings of the chemical high-temperature reaction equipment and heating equipment.

5.Thermal insulation for the furnace door and roof.

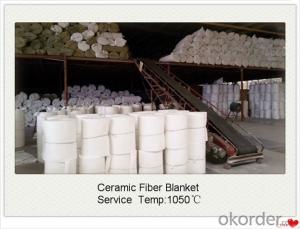

Images

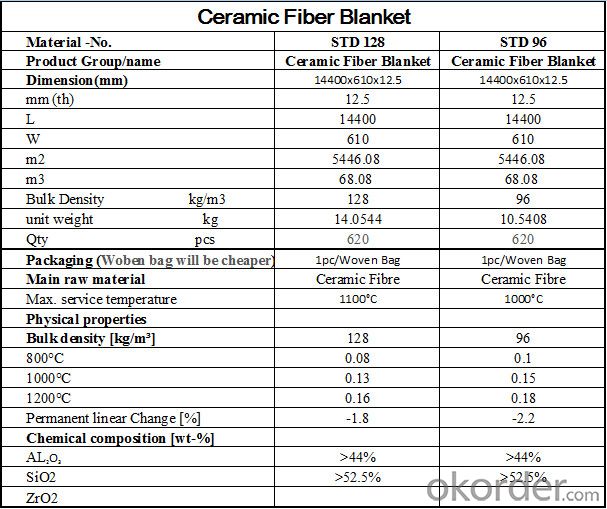

Technical data of Ceramic Fibre Blanket

FAQ

Q1:Are you a manufacturer or trader?

A:Manufacturer+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your products?

A:The service life of different ceramic fiber is unlike.It also depends on your using condition and method.

- Q:One that could be used as a meal substituteAnd do you need to add yogurt or milk to the smoothie? Could I just use water and ice or something? I have juices here, but they're grapefruit and cranberry and I don't like either of them much (my parents bought them to mix and use in special drinks at Christmas.)

- There are plenty more if you GoogleGood luck and good health!! ?

- Q:Can anyone tell me if this is worth the cost of getting it done? Did you notice a big change when done? thanks

- HeyEvery type/make of sub and amp will work togever aslong as the Watts on the amp are higher than the subnd also that the wiring is all correctTo get the best answer for this u shud ask a specialist or halfords

- Q:Want to know which is the Bamboo speces grown for manufacturing yarn from Secondly what is the most ecofriendly method for drawing yarn from Bamboo.

- You know bamboo is grass.

- Q:I am doing a home economics project and need to find food pyramids for a low choleterol diet.high fibre diet.low fat diet.low salt diet.low sugar diet and a gluten-free/coeliac diet.if you know where i can find any of these please tell me.

- Aluminum has the same resistivity for all shapes, but RESISTANCE is determined by Area resistivityIt has to do with current flowCurrent has a harder time flowing through a narrower cross section.

- Q:I went to the doctor Friday because I have been having many of the symptoms of diabetes for a couple of weeks and a few others for several monthsThe doctor said that he thought it was most likely diabetes but then he checked my sugar level and it came back well within the normal rangeI hadn't had much sugar for several days because I really had trouble at work after having a CokeI hadn't eaten much of anything that day, and I had been essentially working out all morning at work (I work retail and spent the hours before the doctor's visit unloading a truck full of heavy merchandise)The doctor is going to do a 3hr glucose test sometime this week if nothing pops up in the blood workIs it possible that, given the circumstances before the random check, I had managed to get the glucose level normal but that I still have diabetes or is it more likely that something else is causing the problem? There is obviously something wrong, but so far we haven't figured out what it is.

- YesThey have been doing so for millenia.

- Q:I live in Minnesota, and have 6-8 inches of blown-in insulation in my atticI looked around various sites trying to find out what R-value that would come out to, and it seemed like it was the bare minimum I should haveHaving an oil fueled furnace, it is expensive to heat my home, so I am looking for the best ways to improve efficiency.

- Most of the heat loss in a home does not go out windows or doors but up and out through the atticAdding more insulation to the attic is always a good idea.

- Q:I have a gas stove that the rats got into and made nest in the sides of my gas stoveCan the insulation be removed or replaced?

- I know exactly how you feelI was about 60 pounds overweight (according to my BMI) and for a while I really wanted to just starve myself because I was sick of being fatExcept, it really isn't the answerThe moment you try to drastically restrict what you eat, your inhibitions go straight out the door and suddenly you find yourself craving things you never did beforeI realized how insane I was to think it would just be a fairly simple task to not eat, and do tons of exercise, so I joined weight watchers insteadAnd now I've lost almost 30 poundsSlow and steady wins the race, it really does, and if you want to keep the weight off, instead of going on a crazy rollercoaster of weight fluctuation that would probably end up in you gaining more weight than you did before, then you need to do it at a rate of no more than like 2 pounds a week.

- Q:I was diagnosed with porphyria last nightI am only 20 years old and I have been sick for five yearsI am not sure which porphyria I haveI have to get an hemotoligistI was wondering if I could sherbert or eat ice cream or yougart with porphyria.

- oh my god ! thats toooooooooo many

- Q:How is fabric made?

- just me again - totally agree

- Q:I know yogurt doesbut is there anything else?

- Yogurt? I'd not heard that one If you change your eating habits to 4 - 6 small meals a day, your metabolism will burn a at a higher rate all day, to process the food you eat.versus 3 meals when it slows down in the longer breaks between mealsResearch suggests that spicy foods can increase metabolism, though only to a minor extentMetabolism boosters Capsicum (cayenne or red pepper)—the active ingredient capsaicin is supposed to raise the body's metabolic rate by as much as 25 percent for three hours (Greenwood-Robinson) 1/8 tspdaily (Greenwood-Robinson) Hot chiles—post-meal metabolism builder Hot mustard—another post-meal metabolism builder Flaxseed—contains 5 grams of soluble fiber per tablespoon; the 1 source of alpha-linolenic acide (ALA), a fatty acid essential for efficient metabolism 3 Tground flaxseed daily (Greenwood-Robinson) Cinnamon—chromium, which controls blood-sugar (see article on USDA site) 1/2 tspground cinnamon daily (Greenwood-Robinson) Green tea—Green tea (in fairly large amounts) increases your metabolismI might not drink that much (3 cups a day or more), but I figure even a little bit is worthwhileStrawberries—Besides being sweet and delicious, strawberries have few calories, high fiber and a lot of vitamin CThe vitamin C stimulates production of carnitine, an amino acid that supposedly boosts your metabolismYou can put your search engine to work (as I did) and find more?

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polycrystalline Mullite Fire Blanket for Glass Kiln Made In China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products