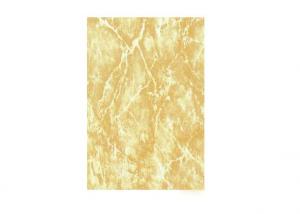

Polished Porcelain Tile The Soluble salt Matt Yellow Color CMAXSB0514

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1382.4

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

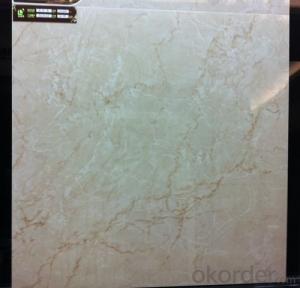

Product Features Polished Porcelain Tile The Soluble salt Matt Yellow Color CMAXSB0514:

Polished Porcelain Tile, Double Loading

Only Grade AAA available

Strict control on color shade, deformation, anti-pollution, surface glossy degree as well as packing

Competitive price

Standard export packing: Pater Carton+ Wooden Pallet

Fast delivery

OEM service could be offered

Marketing support on samples, catalogues as well as carton designing

Professional sales team for product, document and schedule of importing and exporting.

If you ask me,what do you live for?

Maybe there is only one reason:I love life.

In the place where I live,I would like to put my life taste into the space decoration. I try to find what will help me?Until one day,my family travel to one seaside,I was shocked by what I saw,high mountain and clear water and green trees in front of me,what a wonderful scene! Can I take the beautiful things to my home?At that instant,suddenly I feel that life and porcelain should be the best partner.

Nature,space,design,which of porcelain is what I am happy to share with you.

Life and Porcelain,Love and Passion,the story is going on

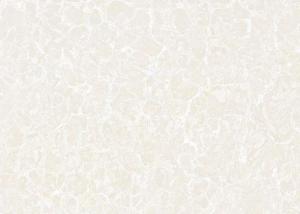

This series of products in addition to good wear resistance with ultrafine tiles, flexural strength,

and low water absorption, the appearance of the product, due to be fired into a crystal frit, so

three-dimensional effectprominent, white the texture clear, natural, delicate harmony and balance without duplication, with impeccable decorative effect, close to natural stone.

Product Specification

Tile Type: Polished Porcelain Tile

Quality standard: GB/T4100-2006, ISO13006, ISO9001

Water Absorption Rate: 《0.5%

Breaking Strength: 》 1800 N

Rupture Modulus: 》40 MPa

Length and Width Tolerance: ±0.1%

Surface Smoothness: ±0.15%

Edge Straightness: ±0.15%

Wearing Strength: 《1600 mm3

Glossiness: 》 85 Degree

Resistance to Chemical: Class UA

Resistance to Staining: Class 3.

Packing Information (For 27.5 Tons heavy 20’Fcl)

For 600x600mm, 4pcs/Ctn, 40 Ctns/Pallet, 960 Ctns/20’Fcl, 1382.4m2/20’Fcl

For 800x800mm, 3pcs/Ctn, 28 Ctns/Pallet, 616 Ctns/20’Fcl, 1182.72m2/20’Fcl

Production Line & Package

FAQ

1. For Polished Porcelain Tile, is the 30*60 available?

—— Yes, 30*60 is available. Due to the basic size is 60*60, we need to cut 60*60 tile into 30*60. 6 pcs are packed into one carton.

2. What is the MOQ for this tile?

—— Normally the MOQ is 1382.4 m2 for one 20’ container. To support our clients, we could go with 3 models to fill one container at most.

3. Can we use the carton with our own design and brand name?

—— Yes. Normally we go with Neutral Carton or our Carton with our CMAX brand name. But for carton of client’s own design, the MOQ for one size is 5 containers, due to the carton factory can’t arrange production if quantity is below 5000 pcs.

- Q:It‘s been a while since I have done tile, but I remember we used to use sheetrock to cover the floor or for back splash wall, however I don‘t remember what it was used for. Is there special cases when you need to use it or do I need to use it every time? What is the purpose to use the sheetrock?Please help. Thanks.

- It may have been sheetrock that you remember but more than likely it was some type of special backer product that resembled Sheetrock but was made specifically for use under tile. There are several types available at Lowe's like hardibacker or durarock. Both of these products are designed to be placed on the surface to be tiled before the tile is applied and act to stiffen the substrate. In other words they make the surface that the tile goes onto into one big solid piece as opposed to several sheets of plywood. The benefit of this is that is keeps the tiles from moving in relation to each other which will cause the grout lines in between them to crack and gap. These products are generally put down, when tiling floors, on top of a layer of mortar same as you spread mortar to hold the tiles down. Ans then these backer boards are nailed down with roofing nails and the joints are mortared and usually taped like drywall joints are. Then more mortar is spread on top of these boards and the tile is set into this mortar. Floors generally use the 1/4 thick backer board and when applying on walls the 1/2 backer is used. Just nail to the studs and paint with a waterproofing paint then mortar and apply tiles. Good Luck.

- Q:Has anyone every used Ceramic Tiles to re-do bathroom floors? I‘ve seen it done on HGTV but just wanted to knw if it was really that easy?

- If you buy a good tile cutter , take your time and use spacers it is pretty easy. It takes a few days because you have to let it dry good before grouting. Then you need to let the grout dry for at least one day before you seal it .IT MUST BE SEALED . Or all your work will be for not. If it is your first time I would suuggest using smaller tiles, easier to cut. And NEVER start in a corner!

- Q:A few tiles in my building flat give a cracking noise when i step on them.Upon inspection i found that the tiles make cracking sound even when i press them with my hands but requires some strength.There is a small airgap in a few joints but the gap is very small.The tiles were installed almost 15 years ago and i dont know how old the building is but is considered an earthquake proof structure.The cracking sound is sometimes even for as long as 1-2 seconds when standing on it.So is it a lose tile or a foundation crack?

- You say the tile floor was installed about 15 years ago, which would make me think that the thin-set mastic used to adhere the tiles to the floor has dried out and allowed several of the tiles to loosen on the mastic bed. This allows them to move, albeit ever so slightly, each time you step on them. If the problem is not resolved soon the cracking sound will increase and there's a good chance the tiles themselves will crack and then need to be completely replaced. This could be sort of difficult seeing as how you'd be attempting to match 15 year old patterns. The repair is to remove the affected tiles, then remove the old thin-set mastic, being careful not to disturb the surrounding tiles, reapply new mastic and then re-set the tiles. Allow them to set overnight, undisturbed and the next day re-grout the cracks. If you don't feel comfortable doing the repairs or if it's not your building, either get your landlord involved or hire a flooring guy yourself.

- Q:I‘m remodeling my kitchen back splash and bathroom shower and i love the Moroccan tiles. Does anyone know any source for Moroccan tiles in San Francisco, California?

- The okorder / Cheers, and Good luck Anna,

- Q:I want to buy six glass tiles for my science project but i don‘t know where to buy them. There are windows for sale but I don‘t want to use hundreds of dollars for a window.

- While okorder

- Q:I‘m going to be putting in a tile floor in my kitchen (all cabinets and appliances removed). I have done my research and have a good idea of what I will be doing - beef up the subfloor with plywood and lots of screws for rigidity; use cement based self leveler to correct a mild slope; install backerboard or decoupling membrane (not sure which yet) followed by the tile.I have a plan, but plans tend to fall apart after their first run-in with reality. Has anyone run into types of problems they don‘t talk about on DIY network? The types of problems complete the following kinds of sentences: are you f***ing kidding me? You have to do ____ before ___? or dammit, why don‘t they tell you you need [insert name of specialized gadget] on a product that cures in 10 minutes? or boy was I an idiot for doing/not doing [insert critically important but not obvious tiling procedure here].?Much obliged, and thanks for the responses.

- Get the proper trowels for the size of tile your doing. Get the proper drill and paddle to mix the thin set Mix the grout by hand or you ll incorporate air into the grout , weakening it.. They don t always show the proper way to lay out tile. Speed squares come in handy, Use a fine tipped marker, pencil marks will come off most tile doing it through a wet saw. Rent a wet saw or if you plan on tiling again, save money in the long run and buy a medium grade saw. With a stand if possible. Any questions you can e mail me through my avatar and check my qualifications there. GL Btw I ll edit my post if I come up with some other hints, I m sure there are.

- Q:I‘m installing 13 x 13 cermic tiles. We‘ve laid the tile to try to configure the best layout. However, the one with the best layout with the easiests cuts leaves one very complicated one. The tile lies directly on the air duct, with the cut being a large rectangular hole in the middle of the tile. If we adjusted the layout to have 2 tiles lay over the duct, it creates more complicated cuts everywhere else.How do you suggest I cut this tile?We have only a wet tile saw.

- Get a ceramic tile drill bit and a coping saw with a diamond encrusted blade. Drill a hole in the tile. Slip the coping saw blade through the hole and attach it to the saw. Cut out the rectangle for the air vent.

- Q:this tile i‘m buying is pei 5 and breaking point of 450 lbs. 24x24 inch. at a $1.60 sq/ft. is this a good tile?

- pei refers to the slip resistance of the tile . Thats the highest rating buttttt, most all porcelains are rated this high. 5 rates the tile at a commercial usage which will take heavy foot traffic The tinsel strength is just average. So overall its not a bad tile. The absolute most important thing is the proper setting technique. Not setting it properly and over the correct sub floor , it doesn t matter what you get. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q:I want to know if it‘s necessary to use any special underlayment, or any additional steps required to successfully lay ceramic tile over a wood plank floor. Thanks!

- The right way to do it would be to remove the flooring and lay down some hardi backer or some cement board. However - if your wood floor is very very flat, and you consider the areas where that wood floor + the thickness of your tile meets up with other floor surfaces (e.g. carpeting or door door thresholds), it might be the easiest thing to do. Tile is a lot of fun. Don't skimp on making the right cuts and be sure to use spacers. Depending on what kind of tile you use - go with a smaller (1/4 or less) spacer so you have less cleanup with your grout. [Edit - I definitely agree with Crazy Man below. The waterproofing layer is a definite! Make sure you give it adequate time to dry, and then make sure you let the mud (adhesive) dry completely before grouting.] You might also consider something other than ceramic tiles, although there are some newer styles that are quite nice. A sealed porcelain tile or slate looks so nice.

- Q:Dear Sir/Madami have question regarding installing tiles 30*30cm*2.5cm thick for hall and rooms my question is whats the min. and Max. cement mortar must be placed under neath tiles (i.e bond coat in between concrete slab and tile )please advice and thank for help and appreciated

- If you're using ceramic tiles (very regular size and relatively smooth/even back), use a 1/4 square notched trowel, held somewhere between 45 and 90 degrees (vertical). If you're using natural stone tiles (e.g. granite, marble, slate), go for 3/8 square notched trowel and back-butter the tiles. Make sure the concrete slab is clean, sound, free of cracks and level before you start and follow the instructions for your thinset. You'll likely want to use a modified thinset which will help bond to the concrete better. If you have any doubts about the stability of your slab, consider installing an isolation membrane between the tile and slab. Schluter's Ditra system is the best of the breed for this. If you use an isolation membrane, use unmodified thinset (instead of modified).

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polished Porcelain Tile The Soluble salt Matt Yellow Color CMAXSB0514

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1382.4

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products