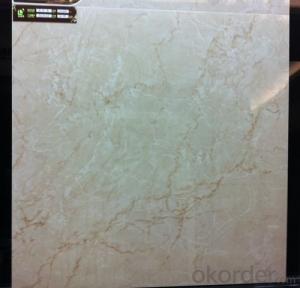

Polished Porcelain Tile The Pilate Blue Color CMAXSBJ1232

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1325 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Primary Competitive Advantages of Polished Porcelain Tile The Pilate Blue Color CMAXSBJ1232:

Experienced Staff

Form A

Green Product

Guarantee/Warranty

Military Specifications

Packaging

Price

Product Features:

Adopt international advanced ceramic cloth exquisite processing technology, selected high

quality pure raw materials, on the product body, with moist and gorgeous color, microcomputer

total precision control, multiple temperature control forming technology create gorgeous texture

hd grain boundary, bottom dense embryo thicker, pure texture, deduces the natural stone material through the external environment and the

geological characteristics and the dynamic form of change,

also make products with high hardness, high gloss, low water absorption, strong dirt resistance, easy

to clean, etc excellent characteristic.

Main Export Markets:

Eastern Europe

North America

Mid East/Africa

Central/South America

Asia

Western Europe

Austra

Product Picture :

Production Line :

Oversea Branch :

Product Certificate :

Packing Details :

FAQ

1. For Polished Porcelain Tile, is the 30*60 available?

—— Yes, 30*60 is available. Due to the basic size is 60*60, we need to cut 60*60 tile into 30*60. 6 pcs are packed into one carton.

2. What is the MOQ for this tile?

—— Normally the MOQ is 1382.4 m2 for one 20’ container. To support our clients, we could go with 3 models to fill one container at most.

3. Can we use the carton with our own design and brand name?

—— Yes. Normally we go with Neutral Carton or our Carton with our CMAX brand name. But for carton of client’s own design, the MOQ for one size is 5 containers, due to the carton factory can’t arrange production if quantity is below 5000 pcs.

- Q:I have a rental that currently has sheet vinyl in the kitchen that is in bad shape. I am considering putting in self adhesive floor tiles over the vinyl. I have installed similar flooring in a bathroom but used inexpensive tiles. It looked good, but the tiles tended to slide. I‘m thinking it was because I used bargain tiles rather than better quality.I just need comments as to longevity and problems you might have encoutered with self adhesive tiles. Also, do you have any particular brand or type you recommend?

- We put the vinyl self stick tiles in the basement over an existing floor. The original tile is from the 50's and contains asbestos. The home inspector said it would be best to leave it down and tile over it.....fine as long as you don't try to take it up..that is where the asbestos comes in. Needless to say the floor has been down for 3 years and still looks great. In the kitchen, we put a vinyl tile floor down over the exisitng vinyl. There was a second floor down, but we took it up. They stick great...only problem we had was where the dishwasher and fridge are. Couldn't tile all the way under them and they kept sliding. My husband fixed that problem with Gorilla Glue. They are going no where now!!!! Both floors are from Home Depot. These were the ones I liked best and they were the most inexpensive. Since this is a rental and you don't want to spend a fortune, go with a pretty but inexpensive floor!!!!!The brand name is NEWPORT. I am very happy with these floors!!!!!! Also make sure exisisting floor is clean; get rid of old wax and grease and dirt. You can buy something at Home Depot to clean this. Make sure tiles are at room temp before laying...don't bring in from cold car and stick down. Good Luck!!!!

- Q:is it fine to set ceramic tiles over existing vinyl flooring?would it be better to use mastic or mortar?how to prepare such a surface?tia

- tia, okorder /

- Q:How to choose the difference between tile types

- 2, quintana bricks Quintana brick is a wear-resistant brick, the surface is not glazed, positive and negative color consistent, its color than glazed tiles. The whole body brick is widely used in the hall, aisle, outdoor walkway and other renovation projects on the ground. Nobel tiles manager told Xiaobian, in the simple plain home furnishings style, quintana brick by a specific crowd of love, more and more become a fashion. 3, polished tiles Polished brick is the surface of the whole body polished by a kind of bright brick, is a kind of quintana brick, compared to the whole body brick, the polished surface of the polished to be much cleaner, polished hard polished polished, suitable for washing in the toilet , The interior of the kitchen is used outside the interior.

- Q:How does the concrete on the tiles clean?

- Water bubbles, and then use the clean ball can be washed off

- Q:Or can I just start tiling over the painted wall?

- The short answer is you dont NEED backerboard. Before backerboard came into widespread use, tile went directly on wallboard. But, you'd be well advised to use backerboard. Tile used to fail in those old days. It is much less likely to fail today because tile setters routinely used backer board.

- Q:Easiest way to remove stick tile

- You okorder /... You may also need to use some type of solvent or cleaner if you want to remove all of the glue.

- Q:My kitchen floor is ghastly and I want to change the floor. I could replace the tiles but it would be more work, but I could also get some linoleum and only have to measure. Just wondering which of the two is better to keep up.

- You can lay tile over linoleum as a short term solution. Eventually the mortar will break down the surface of the linoleum and begin to cause problems. If the subflooring is a concrete slab then just remove the linoleum and adhesive. If the subflooring is wood then just install 1/8 or 1/4 underlayment right over the top. Just remember if you have a dishwasher to remove it and tile underneath it. This will make it easier if the dishwasher ever has to be repaired or replaced.

- Q:I was thinking of installing ceramic floor tiles for countertop in order to save money. I will use 1/16 joints with a dark tile and dark grout. The edges will be mahogoney or oak. I would think that floor tile would hold up better because it is thicker and more durable. Anybody have experience with installing this type on counters? tx in advance..

- Sure just pick out what you want get going on it.

- Q:I am about to renewing my kitche.I plan to install tile.Well I have no tile cutter but I do have a simple, regular cutt off electrical tools and a diamond blade.Should this be enough for it?

- Based okorder /

- Q:If you can tile on top do i need to prepare the old tile surface?

- yes you can

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polished Porcelain Tile The Pilate Blue Color CMAXSBJ1232

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1325 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products