Polished Glazed Tile The Wooden Line Stone CMAXSB1400

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1325 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Key Specifications/Special Features of Glazed Tile :

1. Material: glazed porcelain

2. Antique feel, Metal Image

3. Low water absorption

4. Strong in hardness

5. Coordination in color and luster

6. Usage Area: home, office, hotel, government and corporate projects, flooring tiles, deluxe clubs flooring

7. Style: simple, classic, elegant and splendid in color

8. Good in abrasion and chemical corrosion-resistant

9. Resistance to thermal shock

10. Available in various sizes and colors

Primary Competitive Advantages of Glazed Tile:

1. All product of rustic ceramic tiles are of top grade AAAA

2. CE certificate, ISO9001:2008 and ISO14001:2004

3. OEM accepted.

4. Speial dimensions available according to your floor tiles request.

5. Best Quality with best price, strictly quality control.

6. On time delivery, in general 7-10days.

7. Best after sale service, customer can follow their porcelain tiles order situation any time. no matter on product line, warehouse or shipment.

Main Export Markets:

1. Asia

2. Australasia

3. Central/South America

4. Eastern Europe

5. Mid East/Africa

6. North America

7. Western Europe

Specification:

Tile type: | Ceramic tile |

Material: | Porcelain |

Size(MM) : | 600x600mm |

Thickness(MM): | 9mm |

Water Absorption: | ≤0.5% |

Color: | Available in all designs and colors |

Usage: | Used in floor |

Surface treatment: | Glazed surface |

Features: | Professional triple-burning in oven, which makes our tiles more excellent quality. |

Function: | Acid-Resistant, Antibacterial, Heat Insulation, Non-Slip, Wear-Resistant, Anti-fouling easy to clean |

Packaging: | 600x600mm: 4pcs/box,28kg/box,standard cartons and wooden pallets packing |

Remark: | All kind of designs can be produced according to your requirements |

Quality | |

Surface quality: | 95% tiles no defect from 0.8 away uprightly |

Breaking strength: | As require |

Resistance to thermal shock: | Without crack and flaw after 10 times anti heat shock test |

Brightness: | ≥55 |

Frost-resistance: | No crack or spalling after frost resistance test |

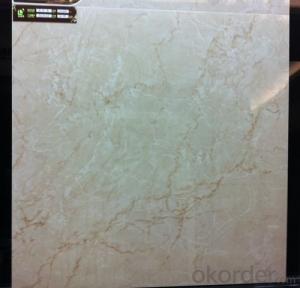

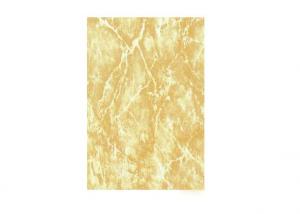

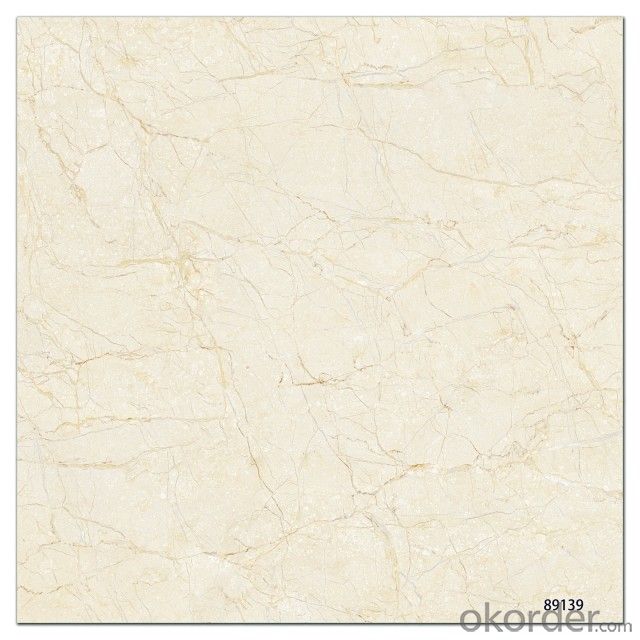

Product Picture:

Packing Pictures

FAQ

1. For Polished Porcelain Tile, is the 30*60 available?

—— Yes, 30*60 is available. Due to the basic size is 60*60, we need to cut 60*60 tile into 30*60. 6 pcs are packed into one carton.

2. What is the MOQ for this tile?

—— Normally the MOQ is 1382.4 m2 for one 20’ container. To support our clients, we could go with 3 models to fill one container at most.

3. Can we use the carton with our own design and brand name?

—— Yes. Normally we go with Neutral Carton or our Carton with our CMAX brand name. But for carton of client’s own design, the MOQ for one size is 5 containers, due to the carton factory can’t arrange production if quantity is below 5000 pcs.

- Q:It‘s been a while since I have done tile, but I remember we used to use sheetrock to cover the floor or for back splash wall, however I don‘t remember what it was used for. Is there special cases when you need to use it or do I need to use it every time? What is the purpose to use the sheetrock?Please help. Thanks.

- It may have been sheetrock that you remember but more than likely it was some type of special backer product that resembled Sheetrock but was made specifically for use under tile. There are several types available at Lowe's like hardibacker or durarock. Both of these products are designed to be placed on the surface to be tiled before the tile is applied and act to stiffen the substrate. In other words they make the surface that the tile goes onto into one big solid piece as opposed to several sheets of plywood. The benefit of this is that is keeps the tiles from moving in relation to each other which will cause the grout lines in between them to crack and gap. These products are generally put down, when tiling floors, on top of a layer of mortar same as you spread mortar to hold the tiles down. Ans then these backer boards are nailed down with roofing nails and the joints are mortared and usually taped like drywall joints are. Then more mortar is spread on top of these boards and the tile is set into this mortar. Floors generally use the 1/4 thick backer board and when applying on walls the 1/2 backer is used. Just nail to the studs and paint with a waterproofing paint then mortar and apply tiles. Good Luck.

- Q:So I have the substrate ready, the room is a L shape 253 x 148. Where do I start the tile, I am assuming the center of each on a chalk line. Is this correct?Bond

- As others have said, start in the center and make your cuts all on the edges, but be careful you don't end up with a sliver of tile. Measure and pencil in the center of each leg of the L, so your chalk lines make an X at the center of the corner where the two parts meet. Then measure away from that line to see how each tile will get cut at the walls. If there is a pattern with strong lines on it, you have to be careful to lay out the cuts so that if there is any taper, due to the floor being not perfectly square...that you don't have cuts going across the lines and accentuating the error. So think ahead! If you can't help but have a funny edge, see if you can put it on a side that is covered with furniture, or isn't that visible in normal use. Do the same with the tile in the other rooms...do some measuring, and see what layout gives you the best size tiles. You don't want to have small tiles at the transitions from one room to another. Adjust your X starting point so your cut tiles are not too small. You should lay it out so you can use the biggest tiles you can (in other words, don't cut little strips to fill in a gap...shift the whole centerline over to make those slivers at least a 1/3 tile. Once you have your X starting point, put down 4 tiles around that X, and work out from the center, but don't run all the tile down the lines, then do another row, etc.. out in an expanding pattern. If you do a long run all at once, and are just off by a tiny bit at the start...the error with keep growing. Work out from your starting point, filling in all the floor as you go, leaving the edges to trim last. I strongly recommend the Time-Life books on this.

- Q:How does Tengzheng build tiles on the elevations?

- double-click back to the pattern fill interface, Select the ratio, in the right border option, click Add to pick up the object, select the range you want to fill, you can enter.

- Q:Anyone know if that type of ceiling tile has asbestos? Unsure of the year built. It has a texture to it which is why I‘m worried about it.

- Like others have said it's imposable to tell without testing. Asbestos is very expensive to remove and the tile if left alone (kept sealed with paint) is safe.

- Q:I‘m installing 13x13 floor tile on a slab. Any tips on how to do it right

- If your not overly familiar with doing tile a diagonal isn t the easiest to start on. Lay out and proper tools are a big help in your preplanning. Right size trowel and large enough wet saw and had cutter is a must. Get the longest straight site line and split the room in 1/2 with a chalk line. Lay tile back to the wall and figure the size of pc(pcs) you need. You can cut a few of these pcs as a starting point. Knowing you split the room you should be equal when you get to the other side. A perfect straight edge will help keep your lines straight. Use this on all sides as you build out from that wall and lay as though your doing a straight lay just that your on a 45 degree. Or if you are doing an open ended area , you can cut several tiles in 1/2 and work back. A bit trickier but overall look is better. Don t cut tiles directly in 1/2, you must cut just off center if this is a starting point. Very hard to do and takes experience. Any specific questions you can e mail me through my avatar and check my qualifications there. GL

- Q:We have ceramic tile on the wall in the bathroom with a few tiles of color. Hate to change whole bathroom.

- I don't know much about tile.But I've taken a few ceramic classes And I know when you glaze you have to put it in a Fire Kiln. To even activate the glaze. And I was taught if you missed a spot, and was to put more glaze on and fire it again, it could crack or burn the ceramic. I don't know how this works on tile though. (they come already fired from the factory don't they?) Maybe you could remove the current glaze somehow? And then do a glossy paint. Because if tile is anything like ceramics you'd have to take it off the wall and fire it again. Sorry I don't know anything about tile.

- Q:How much does it cost for a professional removal of asbestos tile in a 19x25 room? and where can i find a contractor in Gainesville, FL? and is it safe to put tile over asbestos tiles?

- Tile over the existing material. Asbestos is only harmful when inhaled into the lungs, so just leave it alone. I have never heard of having to abate asbestos when selling a house - if it was, housing resale in this country would grind to a halt and the asbestos abatement business would not be able to keep up. Just about any house that was built before 1970 has it.

- Q:We have small ceramic tiles on our bathroom floor. They are varied in shape and size (see photo).I think that these tiles originally came with some sort of netting on the back when they laid the floor and they added grout? I believe I saw some extra tiling somewhere in our home and this is what I had found.Anyway, the grout is breaking up between some of the tiles and some of the tiles keep popping out. I have two questions, If I regrout them do I put it on the bottom of the tile too and does that make the tile adhere to the floor?How would I get the grout to match what‘s already there, it‘s a medium brown gray. Not sure if it started out that way or became like that over the years. Would it look funny if the grout didn‘t match? How could I get it to match?

- I okorder /

- Q:Dear Sir/Madami have question regarding installing tiles 30*30cm*2.5cm thick for hall and rooms my question is whats the min. and Max. cement mortar must be placed under neath tiles (i.e bond coat in between concrete slab and tile )please advice and thank for help and appreciated

- If you're using ceramic tiles (very regular size and relatively smooth/even back), use a 1/4 square notched trowel, held somewhere between 45 and 90 degrees (vertical). If you're using natural stone tiles (e.g. granite, marble, slate), go for 3/8 square notched trowel and back-butter the tiles. Make sure the concrete slab is clean, sound, free of cracks and level before you start and follow the instructions for your thinset. You'll likely want to use a modified thinset which will help bond to the concrete better. If you have any doubts about the stability of your slab, consider installing an isolation membrane between the tile and slab. Schluter's Ditra system is the best of the breed for this. If you use an isolation membrane, use unmodified thinset (instead of modified).

- Q:I want to put vinyl tiles on my pre-existing ceramic tiles but in some areas there is no ceramic tiles and I need something to fill in the gap to make my floors even when I put on the vinyl tile. What should I use? Then when my floors are even how do i put my tiles?

- If you insist on installing vinyl tiles over the ceramic....first you need to abrade the surface of the ceramic, then you need a high quality floor leveler, such as Ardex to skim over the entire floor and fill in the grout joints. In the areas without tiles, you can use plywood to build up to the level of the existing tile. Make sure to skim over the plywood joints as well. Hopefully, you are not using the peel and stick tiles, because over time they do not stay stuck to the floor. Use the dry back and put the adhesive on the floor, and the tile in the glue. Just remember - your new floor is only as good as the floor under it...best to rip up the ceramic.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polished Glazed Tile The Wooden Line Stone CMAXSB1400

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1325 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products