Polished Aluminum Alloy Sheets for Metal Walls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Polished Aluminum Alloy Sheets for Metal Walls

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Polished Aluminum Alloy Sheets for Metal Walls

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Polished Aluminum Alloy Sheets for Metal Walls

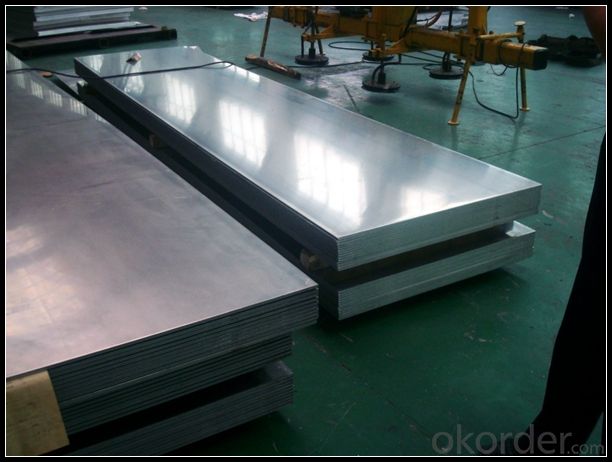

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

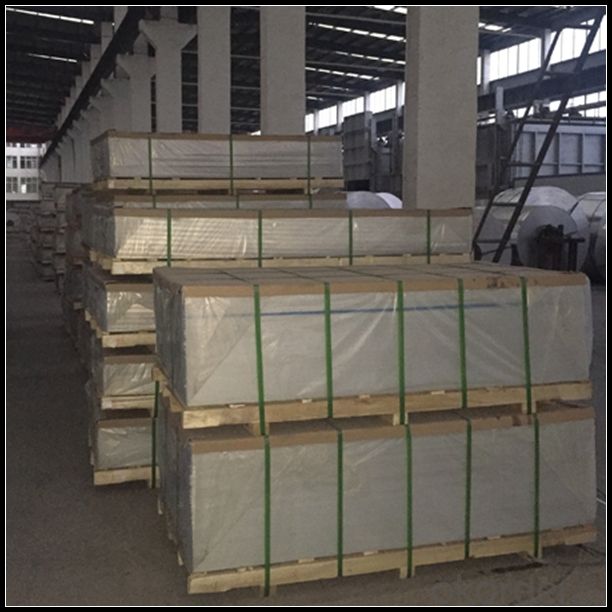

5. Image of Polished Aluminum Alloy Sheets for Metal Walls

6. Package and shipping of Polished Aluminum Alloy Sheets for Metal Walls

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Can aluminum sheets be recycled?

- Yes, aluminum sheets can be recycled. Aluminum is a highly recyclable material, and recycling aluminum sheets helps in conserving natural resources and reducing energy consumption compared to producing new sheets from raw materials.

- Q:which kind of material won't influence magnet attracting iron nail? Does copper sheet or aluminum sheet influence it?

- Copper coil will impede magnetic penetration. People separate the magnet from the workpiece of machine tool to avoid magnetic short circuit and attraction loss, making magnetic line of force go through the workpiece. An opening copper bush is added into the iron core of magnetic closing coil or opening solenoid to avoid the iron core being attracted on the external iron piece and stop operation. The opening is for avoiding eddy formulation and short circuit, iron core in copper bush is the ruled magnetic circuit.

- Q:Are 101 aluminum sheets suitable for automotive applications?

- Yes, 101 aluminum sheets are suitable for automotive applications. 101 aluminum is a high-strength alloy that offers good formability, corrosion resistance, and excellent weldability. These properties make it a popular choice for various automotive components such as body panels, heat shields, and structural parts. Additionally, 101 aluminum sheets are lightweight, which helps improve fuel efficiency and overall vehicle performance. Overall, 101 aluminum sheets are well-suited for automotive applications due to their strength, formability, corrosion resistance, weldability, and lightweight characteristics.

- Q:why does the bubble apear a few minutes later after putting aluminum sheet into dilute sulphuric acid?

- Because there is oxide on the surface of aluminum, the reaction will be quicker after polishing the oxide with abrasive paper.

- Q:Are aluminum sheets suitable for aerospace engine components?

- Aerospace engine components can indeed be made from aluminum sheets. Aluminum is widely employed in the aerospace industry because of its advantageous properties. Its lightweight nature is crucial for aircraft and spacecraft applications, as it aids in reducing overall weight and fuel consumption. Furthermore, aluminum possesses outstanding thermal conductivity, enabling efficient heat dissipation generated by the engine. This characteristic is essential for maintaining optimal operating temperatures. Additionally, aluminum exhibits a commendable strength-to-weight ratio, corrosion resistance, and ease of fabrication. These qualities make it suitable for various engine components like casings, housings, and structural elements. Nevertheless, it is important to note that not all engine components can be solely constructed using aluminum sheets. Certain parts may require higher strength materials or specific alloys to withstand extreme temperatures or stresses. Overall, aluminum sheets have proven to be a reliable and frequently employed material for aerospace engine components. They significantly contribute to the overall performance and efficiency of aerospace engines.

- Q:I saw some pretty horrific pictures today of bow shooters with their hands impale by pieces of a carbon arrow that broke after being shot. I'm about to get into the archery sport, and I just want to know before I buy my arrows, will it be safer to buy aluminum shaft arrows instead of carbon? People said aluminum ones aren't as strong, but right now I'm more concern with the safety factor. Yes, I do know that I'm suppose to always check carbon arrows for cracks before I shoot them, but we're all human and sometimes people will forget and make mistakes. I just don't want my hand embedded with carbon shrapnel. So should I get carbon or aluminum? Maybe the new full metal jacket ones will be a good compromise?As a side note, my first bow will be a recurve somewhere around the 30-35 lb draw range. Does the power of the bow affect the chances of an arrow breakage?

- Sounds like someone was using a traditional, and overdrew and had the carbon arrow come off the rest just as they were releasing it... Thats the 1 and only way i can think of a bow shooter to get bits of a carbon arrow in their hand...That and using a high poundage bow and a low poundage spine carboned arrow

- Q:When water continually sprays on the aluminum sheet, how to avoid corrosion of aluminum sheet and keep its water resistance?

- Don’t worry about it, after aluminum contacts water or air, a layer of oxide film will generate on its surface to separate aluminum from the water or air and protect it, so it won’t be erosive.

- Q:Are aluminum sheets suitable for medical applications?

- Yes, aluminum sheets are suitable for medical applications. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for medical equipment and devices. It is commonly used in the production of medical instruments, diagnostic imaging systems, and surgical trays. Additionally, aluminum sheets can be sterilized easily, further enhancing their suitability for medical applications.

- Q:Can aluminum sheets be painted after installation?

- Yes, aluminum sheets can be painted after installation. Aluminum is a highly versatile and durable material that can be painted to enhance its appearance or match the surrounding environment. However, it is important to properly prepare the surface before painting to ensure adhesion and longevity of the paint. This typically involves cleaning the surface, removing any dirt or debris, and applying a suitable primer to promote better paint adhesion. Once the surface is prepared, any type of paint can be applied to the aluminum sheet, such as acrylic, oil-based, or epoxy paint. It is recommended to consult with a professional painter or follow the manufacturer's instructions for the specific paint product to achieve the best results.

- Q:Can aluminum sheets be easily shaped or bent into desired forms?

- Yes, aluminum sheets can be easily shaped or bent into desired forms. Aluminum is a highly malleable metal, which means it can be easily manipulated without breaking or cracking. Its low density and high strength-to-weight ratio make it an ideal choice for various applications where shaping or bending is required. Aluminum sheets can be shaped or bent using a variety of methods, including press-braking, roll-forming, or using specialized tools such as a sheet metal brake. The ease of shaping or bending aluminum sheets also makes it a popular choice for industries such as automotive, aerospace, construction, and manufacturing, where customized forms and designs are often needed.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polished Aluminum Alloy Sheets for Metal Walls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords