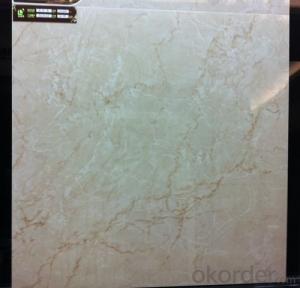

Polish Porcelain Tile Double Loading Series ZSC06183F/C/G

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1267.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Brief Introduction

Polished Porcelain Tile Double Loading Serie Black Color ZSC06183F/C/G is one of the most popular color of Double Loading Serie, which is one serie of Polished Porcelain Tile in the present market. Just like other series, it could be used for interior floor for apartment, villa, super market as well as other public areas, due to its being high glossy and clean, homogeneous color shade as well as the reasonable price compared with natural stones.

Product Features

Polished Porcelain Tile, Double Loading

Only Grade AAA available

Strict control on color shade, deformation, anti-pollution, surface glossy degree as well as packing

Competitive price

Standard export packing: Pater Carton+ Wooden Pallet

Fast delivery

OEM service could be offered

Marketing support on samples, catalogues as well as carton designing

Professional sales team for product, document and schedule of importing and exporting.

Product Specification

Tile Type: Polished Porcelain Tile

Quality standard: GB/T4100-2006, ISO13006, ISO9001

Water Absorption Rate: 《0.5%

Breaking Strength: 》 1800 N

Rupture Modulus: 》40 MPa

Length and Width Tolerance: ±0.1%

Surface Smoothness: ±0.15%

Edge Straightness: ±0.15%

Wearing Strength: 《1600 mm3

Glossiness: 》 85 Degree

Resistance to Chemical: Class UA

Resistance to Staining: Class 3.

Packing Information (For 27.5 Tons heavy 20’Fcl)

For 600x600mm, 4pcs/Ctn, 40 Ctns/Pallet, 880 Ctns/20’Fcl, 1267.2m2/20’Fcl

Production Line & Package

FAQ

1. For Polished Porcelain Tile, is the 30*60 available?

—— Yes, 30*60 is available. Due to the basic size is 60*60, we need to cut 60*60 tile into 30*60. 6 pcs are packed into one carton.

2. What is the MOQ for this tile?

—— Normally the MOQ is 1267.2 m2 for one 20’ container. To support our clients, we could go with 3 models to fill one container at most.

3. Can we use the carton with our own design and brand name?

—— Yes. Normally we go with Neutral Carton or our Carton with our CMAX brand name. But for carton of client’s own design, the MOQ for one size is 5 containers, due to the carton factory can’t arrange production if quantity is below 5000 pcs.

- Q:After completing a bathroom tile job, including a tile baseboard border about 6 up from the floor, we have dried thinset in on the actual wall - places we missed during cleanup. I‘ve tried using some scrapers (plastic and metal), and the dried thinset is like concrete (naturally) and is pulling layers of drywall off with it. Is there a solvent or better way to remove the dried thinset from both the wall and the exposed rim of the tiles? As a last resort I might be okay with slight damage to the walls as they need serious prep anyway before paint, but I do want to make sure i haven‘t missed some very obvious, easier, better solution first.

- I have had tile layers do that to my drywall talking about PO! OK take a razor knife and carefully cut the paper around the grout peel paper away, then skim coat with mud, tapping mud you know loose. Best case if you are going to texture the wall if its not thick on the surface just texture it in. If a tile layer caused this tell him to pay for it or get out of town!

- Q:I‘m getting some of my house tiled and would like to know if I am getting ripped off or not. It is going to be approximalte 600 sq ft with 2 upstairs bathrooms. The installer gave me a quote of $2400 to lay the tile (straight or diagonal, whichever I want). I will have to buy the tile and other materials on my own. The tile is going to be 18x18. The price includes ripping out the carpet and ripping out the tile that is already in the kitchen that will be replaced as well as the tile in the upstairs baths. Also included will be haul away of all the trash. Is this a good price or not?

- I am a contractor and for the work you describe i would usually charge 10 dollars a square foot. But I would include all the material including the tile but not exceeding a certain price per foot. And diagonal is extra so I think you got a damn good deal. Be careful check the guy research now no tears later.

- Q:while laying new floor of tiles, i‘m confused above, which tiles are more durable for floor: homogenized floor tiles or glazed floor tiles, or granite floor tiles

- In a home setting it rally doesn t matter what you use. They ll all out last us if they are properly set. And setting is the key from the floor prep to the glueing of the tile with thin set. Two basic type of porcelains, full bodied porcelains where the color goes through out. The backing is basically the same colored as the front. Then you have glazed porcelains where the tile body is porcelain , the porcelain is baked, there is a color or pattern on the surface and then a glaze is applied. Then there is the standard clay bodied tile where the clay is baked , a color on the surface and a glaze and its refired again. Homogenized tiles, and I m not over familiar with them is a very hard tile that has a very low water absorption rate. All are good products but clay tiles are not as true in sizing as most ( not all) porcelains . Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q:There is a broken tile in my hall, and two of them are loose. do I need to scrape off the old dry morter that was under them? What do I purchase to secure them? mortor, grout or? I noticed that grout comes in many colors- mine is the shade of sand. Also, the one tile has to have a cut out for the door - is there any other way to cut it than with a tile saw?

- Yes, okorder /

- Q:We laid tile in our shower and I used too much grout. Now I need to know how to get the grout lines even without damaging the tile. Any help would be appreciated.

- thats a problem, grout is cement , it will take something thats abrasive, like a wheel grinder, ? got me stumped i,v been at this for 50 yrs, never have figgered that one out,

- Q:Hello! I currently have a 3 season sunroom addition on the back of my home that has been stripped down to the wood. I recently saw a 4 season sunroom that had tile down and needless to say, I fell in love with it! I am thinking about putting tile down in there but am worried about the weather...I live in Minnesota where it gets very cold...and that room is not heated in the winter. Would I have problems with the tile cracking? Or does anyone know of an alternative way to get a tile-looking floor without having to worry the temperature changes??

- Hi, In the UK we have a floor covering which is similar to the wood effect laminate floor, it locks together and looks amazingly like 9x9 tiles. I put it in my bathroom and it is not as cold as tiles to the bare feet. It is a wood/paper based product but is waterproof for the normal house hold duty. I assume that the Minnesota winter will not make it too cold. Use a styrefoam underlay 2mm thick to prevent heat loss. this is a do it yourself job if you are handy with a saw, We know it as TILE LOK

- Q:Bathroom Tiling Job?

- Ceramic tile or vinyl tile? Ceramic tile you need a total substrate of no lees than 1 1/4. This means you need to add a minimum or 1/2 to make it sturdy enough for tile . And the very best ting to use ( for the average DIY) is 1/2 cement board. And this needs to be properly installed. This will comply to ATC and TCA tile codes.. If your using a vinyl tile you possible can go over it all w/o underlayment but I strongly suggest a 1/4 wood underlayment such as luan. This gives you a clean surface to bond to. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q:Used 600x300 glazed tile for the whole outdoor building. 30% tile gum and cement mixed for the work. 6 months later, the Tiles begun to fall off the wall leaving the cement still strongly bonded on the wall. I mean, the tiles ONLY fall donw, not with the cement. Note: We usually soak SOME ceramic tile with water before pasting them, IF the type call for that. But the type is apparently out of the case of water solution.Granite is even heavier than that and yet lasts virtually with building.

- Outdoor Wall Tiles

- Q:I would like to remove some tiles from one area of my kitchen and save as many as possible for use in another area of the kitchen. They are heavy 1979 ceramic tiles. How do I get them up and save some of them?

- Having recently removed a s***load of tile during a kitchen remodel, I wish you luck in saving a whole lot of them! Carefully slide a prybar under the edge of the tile---wiggle til it loosens then use the prybar as a lever to remove the tile. It worked for me. Surprisingly many remained whole without chips or cracks, and I wasn't trying to save them. Just didn't want the huge mess involved in the sledgehammer method. LOL

- Q:Gold tiles and gold medals in Asia which is good

- 7, if it is to buy tiles (wall), then look at the brick body side of the body and glaze between the glaze to see the thickness, too thin can not be, because a long time there will be broken or will There is seepage. Look at the surface of the tiles glaze is bright, glaze light good quality. The above methods 1,2,3 points are common to all bricks, and 4,5,6,7 is a method for different products. The last to add a few pieces of brick weight is a method, the more dense the higher the relative, but this is not useful for all the bricks, for example, now like God God Connaught and several other big brands have a called "light brick "The product, the weight is very light but the quality is also good. So the weight of the contrast can only be used on traditional tile products. If the conditions permit, then the cup of water poured on the back of the brick body to see the water absorption of the brick speed, the faster the harder the brick, the more difficult to prove that the better brick, which is commonly referred to as the ceramic tile water absorption, the general international standards In the following 0.4%, that is, pour 100 grams of water brick will only absorb 0.4 grams, to achieve this standard brick is basically a good brick.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polish Porcelain Tile Double Loading Series ZSC06183F/C/G

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1267.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products