PMB-741 Elastomer (SBS) Modified Bituminous Waterproof Sheet Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Elastomer (SBS) Modified Bituminous Waterproof Sheet Material is a thermoplastic and elastic

modified bituminous dipping and coatingmaterial made out of Stylene-Butadiene-Stylene (SBS),the filler base is polyester felt, glass fiber felt and glass fiber reinforced polyester felt, it is a kind of rollable sheet water proof materials with the surface cover of the isolating materials like polyethylene film, fine sand and mineral slice (or particle) etc.

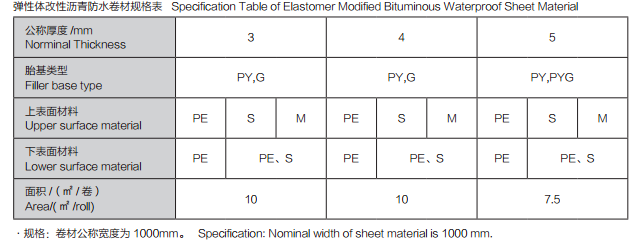

Type and Specification

Classified by filler base: Polyester filler (PY), glass fiber

filler(G) and glass fiber reinforced polyester filler (PYG).

·Classified by upper surface isolating material: Polyethylene

film (PE), fine sand (S) and mineral particle (M).

·Classified by lower surface isolating material: Fine sand

(S) (note: the mineral particle with the fine sand diameter not

more than 0.6mm) and polyethylene film (PE).

·The physical and mechanical properties were divided in

Type Ⅰ and Type Ⅱ.

Advantages

—Filament polyester filler base sheet material:

·The combination of filament polyester filler base and SBS

modified bitumen, forms a high performance and high class

comprehensive water proof sheet material.

·Forming a high strength water proof layer, to have strong

resistance agaist water pressure.

·Good performance of breaking resistance, tearing resistance,

fatigue resistance, corrosion resistance, mould resistance and

weather resistance;

·High tensile strength, high elongation, high adaptive capacity to

base shrinkage,deformation and fracture.

·Good resistance performance of low and high temperature: It

still works under -50 ℃ , adaptive to cold and hot surroundings,

especially in chilly region.

·Good workability: Hot melt cementation, we are able to contruct

in the four seasons of the whole year, hot-joint is able to be reliable

and durable.

—Alkali-free glass fiber filler base sheet material:

·Combination of economical filler base and high performance

SBS modified bitumen.

·Higher tensile strength, excellent resistance to high and low

temperature.

·Good performance of corrosion resistance, mould resistance,

weather resistance and good workability.

—Glass fiber reinforced polyester filler base sheet material:

·We may use mechanical mounting method to construct, and it is

safe and environmentally friendly.

·The product has better dimensional stabiliy.

·Water proof for various industrial and civil engineerings.

·Underground water proof and damp proof for industrial and civil

engineering, and water proof for indoor swimming pool and fire pool

etc.

Application Range

·Water proof for municipal engineering such as subway, tunnel,

concrete road surface, bridge surface, sewage works and refuse

landfill etc.

·Water proof for water conservancy facilities like canal and water

pool etc .

Application range for various filler base and surface sheet

material:

·Polyester felt filler base elastic modified bituminous water proof

sheet material is appropriate to the roof and underground water

proof engineerings of industrial and civil engineering projects.

·Water proof type Ⅱ is appropriate to roof type Ⅰ and Ⅱ and

underground water proof projects.

·Glass fiber reinforced polyester filler base sheet material is

appropriate to mechanically-mounted single layer water proof, but

must pass the wind load test.

·Glass fiber felt filler base sheet material is appropriate to the roof

of structurally stable building and suitable for underground water

proof project.

·Exposed surface is suitable to have water proof sheet material

with non-transparent mineral particle as upper surface isolating

material.

·The water proof sheet material with find sand as surface

isolationg material is appropriate to underground constructioin

project.

- Q:Can a waterproofing membrane be used on precast aluminum surfaces?

- Indeed, precast aluminum surfaces can be effectively protected by utilizing a waterproofing membrane. These membranes are specifically engineered to safeguard various surfaces, encompassing concrete, metal, and other materials, against water infiltration. By acting as a formidable barrier, the membrane effectively thwarts the ingress of water into the precast aluminum surface. This proves to be especially advantageous in locales with elevated moisture exposure, such as surrounding swimming pools or outdoor environments. It is crucial to select a waterproofing membrane that is aluminum-compatible in order to guarantee optimal adhesion and long-lasting efficacy.

- Q:Can a waterproofing membrane be used in permanent or long-term structures?

- Certainly, permanent or long-term structures can indeed make use of a waterproofing membrane. By creating a protective barrier against water infiltration, waterproofing membranes are perfectly suited for structures requiring extended safeguarding against moisture, such as buildings, bridges, tunnels, and underground constructions. These membranes are typically crafted from resilient materials like modified bitumen, PVC, EPDM, or polyurethane, which boast exceptional resistance to water, UV rays, and other environmental elements. A properly installed waterproofing membrane can significantly prolong the lifespan of a structure by thwarting water damage, mold growth, and structural decay. It is therefore highly advisable to utilize a waterproofing membrane in permanent or long-term structures to ensure their robustness and longevity.

- Q:Can a waterproofing membrane be used on precast steel surfaces?

- Indeed, precast steel surfaces can benefit from the utilization of a waterproofing membrane. These membranes are specifically engineered to serve as a safeguard against water infiltration, making them suitable for various surfaces, including precast steel. By acting as a waterproof shield, the membrane effectively blocks water from penetrating the surface and causing any potential harm. It is imperative to ensure that the surface is adequately primed and sanitized prior to applying the membrane to ensure optimal adhesion and efficacy. Furthermore, seeking advice from a qualified waterproofing contractor is highly recommended in order to identify the most suitable membrane type and application technique for the specific precast steel surface.

- Q:How does a waterproofing membrane handle water infiltration from below?

- A waterproofing membrane is specifically designed to handle water infiltration from below by creating a barrier that prevents moisture from seeping through. These membranes are typically made from materials such as rubber, PVC, or modified bitumen, which are inherently resistant to water penetration. When installed correctly, a waterproofing membrane is applied to the surface of a structure's foundation or basement walls, creating a continuous and impermeable layer. This membrane acts as a protective shield, preventing water from entering the structure through the foundation walls or basement floor. The membrane is typically installed in multiple layers, ensuring maximum protection against water infiltration. The layers are often overlapped and sealed together to create a seamless and watertight barrier. Additionally, the membrane may be reinforced with fabric or mesh to provide added strength and durability. In cases where there is a high water table or excessive hydrostatic pressure from the surrounding soil, the waterproofing membrane may be combined with a drainage system. This system helps to divert water away from the structure, relieving pressure and reducing the risk of water infiltration. Overall, a waterproofing membrane effectively handles water infiltration from below by creating a durable and impermeable barrier that prevents moisture from entering the structure. By installing a properly designed and installed waterproofing system, property owners can ensure long-term protection against water damage and structural deterioration.

- Q:Are waterproofing membranes suitable for residential applications?

- Yes, waterproofing membranes are suitable for residential applications. They are commonly used in various areas of residential construction, such as basements, foundations, roofs, bathrooms, and balconies, to prevent water penetration and protect the building structure from moisture damage. Waterproofing membranes provide a barrier against water, preventing it from seeping into the structure and causing issues like mold, rot, or structural damage. These membranes are typically made of materials like bitumen, PVC, EPDM, or polyurethane, which are highly effective in repelling water. In residential constructions, waterproofing membranes are installed during the building process or as a part of renovation projects. They can be applied as a liquid coating or in the form of sheets that are laid down and adhered to the surface. These membranes create a seamless and durable barrier that can withstand the test of time. Additionally, waterproofing membranes offer various benefits for residential applications. They help maintain a dry and comfortable living environment by preventing water leaks and dampness. This, in turn, protects the integrity of the building materials, prolongs the lifespan of the structure, and reduces the risk of costly repairs. Furthermore, waterproofing membranes can also enhance energy efficiency by reducing moisture-related heat loss or gain. By preventing water infiltration, they help maintain consistent temperatures inside the house, resulting in lower energy consumption and utility bills. Overall, waterproofing membranes are an excellent choice for residential applications. They provide reliable protection against water damage, improve the longevity of the structure, and contribute to a healthier and more energy-efficient living environment.

- Q:Can a waterproofing membrane be used for concrete tank linings?

- Yes, a waterproofing membrane can be used for concrete tank linings. Waterproofing membranes are commonly used in construction to prevent water penetration and provide a protective barrier. When applied to the interior surfaces of a concrete tank, a waterproofing membrane can effectively prevent water from seeping into the tank and causing damage. This is particularly important for tanks that store liquids or chemicals, as any leakage can lead to contamination or structural deterioration. By using a waterproofing membrane, the tank can be safeguarded against water ingress, ensuring its longevity and maintaining its structural integrity.

- Q:How does a waterproofing membrane handle water infiltration through cracks or gaps?

- By forming a seamless barrier, a waterproofing membrane effectively addresses the issue of water infiltration through cracks or gaps. Typically constructed from durable and flexible materials like rubber, PVC, or modified bitumen, the membrane possesses the ability to withstand the movement and expansion of the underlying structure. When encountering a crack or gap on the surface, the membrane acts as a seal, halting the water from progressing further. The material utilized in the membrane is impervious to water, signifying that it does not permit water molecules to permeate its surface. Furthermore, the membrane is installed in a manner that encompasses the entire surface area, including any existing cracks or gaps. This guarantees the absence of vulnerable points in the waterproofing system, preventing water infiltration. Additionally, the membrane is designed to possess flexibility. This adaptability enables it to accommodate any movement or shifting of the underlying structure without compromising its ability to repel water. This quality proves particularly crucial in areas where cracks or gaps may emerge as a result of natural settling or movement of the building. All in all, a waterproofing membrane capably manages water infiltration through cracks or gaps by providing an uninterrupted, impenetrable barrier that obstructs water from penetrating the structure. It represents a dependable solution for safeguarding buildings and structures from water damage and preserving their integrity over time.

- Q:Is a waterproofing membrane resistant to mold and mildew growth?

- Indeed, the resistance of a waterproofing membrane to the growth of mold and mildew stems from its specific design, which aims to establish a barrier against moisture infiltration. This impedes water seepage and the subsequent development of mold and mildew. Through the effective sealing of the area, these membranes eradicate the favorable conditions for the proliferation of mold and mildew, such as dampness and moisture. However, it is important to acknowledge that although the membrane itself exhibits resistance to mold and mildew growth, it does not guarantee absolute protection against these issues. Proper installation, regular maintenance, and ensuring adequate ventilation play pivotal roles in preventing the long-term growth of mold and mildew.

- Q:How does a waterproofing membrane handle settlement of adjacent structures?

- A waterproofing membrane can handle settlement of adjacent structures by being flexible and able to accommodate movement. It is designed to withstand and adapt to shifts in the surrounding structures without compromising its integrity or waterproofing capabilities.

- Q:How long does it take for a waterproofing membrane to cure?

- The curing time of a waterproofing membrane can vary due to different factors such as the membrane type, environmental conditions, and the specific product used. In general, most waterproofing membranes need at least 24 to 48 hours to fully cure. During this period, a chemical reaction occurs in the membrane, enabling it to create a strong and impenetrable barrier. However, it's important to consider that curing times can be influenced by temperature, humidity, and the thickness of the applied membrane. It is always advisable to follow the manufacturer's instructions and allocate sufficient time for the membrane to cure before exposing it to any stress or water.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PMB-741 Elastomer (SBS) Modified Bituminous Waterproof Sheet Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords