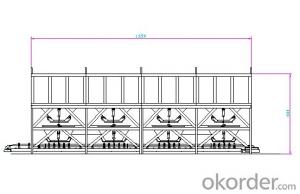

PLD1600-Ⅰ Aggregate Batching Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 2 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PL Series Aggregate Batching Machines are automatic dispensing equipment supporting the use of mixers. They can complete the batching process with aggregates like sands and stones etc. according to the mixture specifications. They are ideal equipment for aggregate dosing for every kind of industrial or civil, large and medium-sized construction projects or precast plants.

PRODUCT & DETAILS

![]() Heavy duty design ensure high reliability and efficiency;

Heavy duty design ensure high reliability and efficiency;

![]() Quantity and size of bins can be customized;

Quantity and size of bins can be customized;

![]() Belt discharge and pneumatic discharge are optional;

Belt discharge and pneumatic discharge are optional;

![]() Accumulative measurement or independent measurement systems can be customized according to your requirements;

Accumulative measurement or independent measurement systems can be customized according to your requirements;

![]() Electronic scale weight components give high accuracy and reliability;

Electronic scale weight components give high accuracy and reliability;

![]() Microcomputer interface, digital display and wired remote control make operation fully automatic;

Microcomputer interface, digital display and wired remote control make operation fully automatic;

![]() Automatic free-fall correction;

Automatic free-fall correction;

SPECIFICATION

Models | PLD1600-Ⅰ |

Weight Bucket Capacity(m³) | 1.6 |

Storage Bin Quantity and Capacity(Set X m3) | 3×3.7 |

Production Rate (m3/h) | 80 |

Accuracy (%) | ±2% |

Maximum Weight (kg) | 3000 |

Type Of Aggregates (types) | 3 |

Feed Elevation(mm) | 3000 |

Belt Speed(m/s) | 1.25 |

Power(kw) | 4×3 |

Equipment Weight(kg) | 4750 |

Dimensions(Mm) (LxWxH) | 9600×2000×3200 |

- Q:Undergraduate engineering machinery major to learn what software ah?

- Other courses may be learning from a subject individually, such as random signal processing in signals and systems. So branch courses vary from school to school.

- Q:In the videos it looks like the plants are taller that are picked by hand. I also know that some plants produce a lot of tomatoes all at once(determinate) and that some grow a long time and produce fruit for months(indeterminate). But I do not know why everybody would not just grow a determinate species and use a harvester.

- any tomatos you see whole and not canned or frozen or bagged have to be hand-picked because they're so fragile. the ones you see being picked by machines are all going towards stewed, canned, pickled, lol, juice, etc etc.

- Q:In law, how many years of depreciation of construction machinery? (excavator)

- People's Republic of China Enterprise Income Tax Law Implementation Regulations belongs to the country level legal norms, the provisions of the law as long as the Department has been abolished, according to the execution, not yet abolished, so in 2012 to continue to press the execution

- Q:what was the first industry to use machinery in production?

- Weaving the loom. Luddites and others like tailors in opposition.

- Q:WE are a Chinese farm machinery( seeder ,planter etc)supplier, really good products, but we don't how to marketing to abroad, really bothered myself.Anyone can give me some suggestion how to marketing, thanks in advance.

- Advertise okorder

- Q:What does CNC in machinery stand for?

- computer numerically controlled. A program of some sort on a computer of some sort directs the operation of the machine, so that it can do the same type of work over and over and over, with little or no human intervention.

- Q:What kinds of books do you need to study in mechanical design?

- Mechanical design manual 5, and then material mechanics, theoretical mechanics, mechanical principles, mechanical design - the University's teaching materials are very good, you can buy second-hand online to buy on the line. Specific industries, as well as construction machinery to hydraulic transmission, and some want to see the precision machinery design

- Q:How do I make cacao butter using raw beans and no machinery?

- Did okorder / . This is able to extremely manage one and all!

- Q:I'm thinking about making something out of wood but I dont have any machinery to do it, all I have Is a saw and a couple knives but that's it. Any ideas?

- Camp Fire!

- Q:how to make paper pellets? i need a small, cheap, transportable machinery.?

- Try pulping and squizing it through a industial meat grinder then drying it in a barrel or old dryer

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PLD1600-Ⅰ Aggregate Batching Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 2 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords