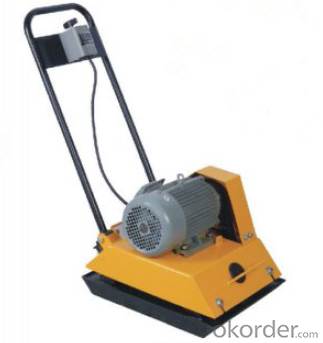

Plate Compactor HZR80-C

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Used for compacting the gravel,soil, asphalt roads, sidewalks, Bridges, car parks, sports venues and the narrow site compaction work. It’s an ideal equipment for highway, municipal departments to build roads, streets, squares.

Easy operation, flexible steering and good welt performance, good shock absorption performance.

Main Product Features:

1. Foldable handle for easy transportation and stock;(straight hand is also available)

2. Open plate provide self cleaning;

3. Radius base plate for easy access to corners;

4. Throttle control for easy holding working speed;(throttle control is optional)

5. Heavy-duty shock mounts reduce vibration to the upper engine and handle;

6. Rubber & canvas mat for brick paving compaction as option.

Product Specifications:

Model: HZR80-C

Engine: Single cylinder, air-cooled, 4 cycles.

Engine Type: Electric Type

Power: 3.0KW

Size of Base Plate: 44cm x 40cm

Centrifugal Face: 13KN

Vibration Frequency: 5500VPM

Compaction Depth: 25cm

Forward Speed: 20-25m/min

Compaction Area: 450m2/h

Climbing Ability:0-30°

Weight: 80Kg

Dimention:67cm x 45cm x 75cm

FAQ:

Q1: Does the Plate Compactor use electricity or diesel?

A1: The Plate Compactor is equipped with famous brand diesel engine.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 20 workdays.

Q4: If we can produce some Plate Compactor according to customers request?

A4: Yes, we can produce Plate Compactor according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q:Strong earthquakes and small earthquakes can be used normally,

- Suddenly a weak is the connecting shaft bearing fault vibration wheel these problems in mechanical problems, there is a problem with this hydraulic system pressure test to determine the need to carefully check the problems in professional roller I ask

- Q:Small roller, that house is of good quality

- Komatsu bar, it is recommended to go to the factory site inspection as well, you can also search Shandong Jin Yao look!

- Q:Difference between single steel wheel roller and double steel roller

- Rubber roller and double steel roller is generally in asphalt concrete pavement use; rubber tire roller plays a role, enhance the degree of fit between aggregate and asphalt concrete, reinforced compactness; double steel roller has the effect of asphalt concrete.

- Q:The roller ensures a good compaction, usually several times

- Count back and forth, usually more than four times.

- Q:Why do different types of roller are used for road laying, initial pressure and final pressure?

- When the roller is rolling, it should follow the first light, the back weight, the first stability, the back vibration, the first slow and the fast, the first edge, the middle back, the first high, the back low and the wheel trace to be heavyThe rolling wheel should be more than the joint of the adjacent two construction sections.

- Q:Now the police, when the general work will be put out, began to work this afternoon has been long bright

- This is the failure lights, according to the situation you say there should be several possibilities: oil filter clogging, filter clogging, pressure sensor failure or blockage in oil, oil pump does not turn you find instructions have introduced one by one investigation

- Q:The role of rubber tyred roller is used for water steady rolling

- Rubber roller and double steel roller is generally in asphalt concrete pavement use; rubber tire roller plays a role, enhance the degree of fit between aggregate and asphalt concrete, reinforced compactness; double steel roller has the effect of asphalt concrete.

- Q:When the asphalt surface is rolled, why should the driving wheel of the roller be geared to the paver?

- The utility model is convenient for following the paver, and the driver is in good control, and the other is that the excess material can be pushed into the non rolling area.

- Q:What are the world famous manufacturers of roller compactors?

- World rollers are well-known manufacturers mainly in Germany, Sweden, the United States and japan. The roller mechanism before several manufacturers mainly in the United States Ingersoll Rand (INGERSOLL RAND, Ingersoll Rand note: the roller's business in 2007 sold to Volvo building Volvo equipment) and Caterpillar (CATERPILLAR), Germany's BMW (BOMAG) and Wittgen (WIRTGEN), Sweden Dynapac (DYNAPAC in Japan, Sakai) (SAKAI).

- Q:How do I do the operation of the roller?

- As long as technical clearance is not required.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plate Compactor HZR80-C

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords