Plastic PVC Pipe Making Machine Extrusion Type

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product introduction

Extruder/Screw And Barrel for Extruder/Plastic Extrusion

Screw Diameter 55 to 65mm

30 to 100 KG/HR

AC20 to 40HP/11.5 to 15KW

Characteristic

Pipe range | 20-63mm single | 20-63mm dual | 75-160mm | 110-315mm | 315-630mm |

Extruder | CMAX51/105 | CMAX65/132 | CMAX80/156 | CMAX80/156 | CMAX92/188 |

Extruder power | 18.5kw | 37kw | 37kw | 55kw | 110kw |

Extrusion capacity | 120kg/h | 250kg/h | 250kg/h | 360kg/h | 800kg/h |

Max. Production speed | 12m/min | 10m/min | 6 m/min | 3 m/min | 1.2m/min |

Process flow

PVC powder + additive --- mixing---feeder---twin screw extruder---mould and calibrator---vacuum forming machine---haul-off machine---cutting machine---discharge rack(or belling machine)

Application

PVC pipe is mainly used in the agricultural water supply and drainage, water supply and drainage construction, cable supporting, thickness of pvc plastic pipe, The lines have conical twin-screw extruder, vacuum calibration tank, haul-off machine, cutting machine, stacker or belling machine and so on. Haul-off machine have two caterpillar, three caterpillar, and four caterpillar, six caterpillar, the cutter use knife-raised cutter or planetary cutter which support chamferring function. And the stacker take into account length, production line is reliable performance, and high quality, we have exported to Egypt, Brazil, Syria, Uzbekistan etc.

Features

1) Main machine uses PVC twin screw, and notch feeder with powerful water

cover cooler, which has greatly improved transmitting capability and ensured

extruding.

2) Adopting double pipe extrusion method, it can greatly increase productivity.

3) Adopting high efficiency double-cavity vacuum calibrating technology and spray-paint

cooler gullet, which improve the finished product passing rate, and meet

the requirements of high speed manufacturing. Vacuum calibrating platform and cooler

gullet are all made of stainless steel

4) Adopting multi-caterpillar haul-off, through the central motor to run all the caterpillar

to reach same height, and ensure roundness of pipes

5) Adopting fully automatic control system with high precision, reliable operation,

easy and convenient handling

6) Suitable pipe diameter: 20 - 630mm

System configuration:

(a) Feeding machine

(b) Conical twin-screw extruder

(c) Mould

(d) Vacuum calibrating tank

(e) Hauling off machine

(f) Printing machine

(g) Pipe cutting machine

(h) Pipe pile-up frame

(i) Auxiliary machine such as mixer, water chiller, belling machine and crushing machine.

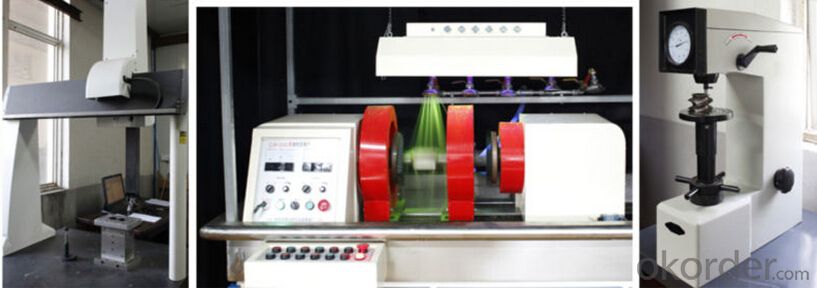

Product show

Our machine types:

1. Co-Rotating Parallel Twin Screw Pelletizing Extruders

2. Single Screw Pelletizing Extruders

3. Die Face Cut (Air Cooling) Pelletizing Extruders

4. Double Stage / Double Degassing Recycling Extruders

5. Crushers, Mixers, Storage Tanks, Vibrators, Granulators, Blowers

6. Extruder spare parts

FAQ

PVC sheet extrusion

*Q: What’s the price of this machine please?

*A: Dear customer, for each kind of our machines, we have lots of models.

Generally speaking, we design the production lines according to

different requirements of different machines from different customers.

Therefore, the prices are different. So please kindly inform us your requirements.

For example, the raw material, the output product size, capacity and etc.

The more detailed, the better. Our Engineers will design a suitable production line for you.

- Q:Does anyone know the operating procedures for the cable 65+120 extruder?

- What are the operating specifications for the extruder?One is the equipment instructionTwo is the boot operation specificationsThree is safety instructions and so onThe equipment manufacturer will provide the above

- Q:Who knows the temperature regulation method of the extruder?Any information will do

- Extrusion molding in plastic processing is called extrusion, using hydraulic pressure in rubber extruder processing in extrusion die extrusion. That itself means that the material through the extruder barrel and screw the function between the side heating plasticization, screw edge is pushed forward, a processing method of continuous head made by various sections of finished or semi-finished products.In the fiber chemical industry is also useful in the extruder to the spinneret for melt spinning. The material, process of extrusion used in thermoplastic plastics and rubber, for batching, granulation, rubber filtration, continuous production, manufacturing various continuous products such as pipe, profile, sheet (or sheets), thin film wire and cable coating, rubber tire, tube noodles barrel, a sealing strip, the production efficiency is high. In the production of synthetic resin, can be used as reactor extruder, continuous polymerization and processing, in rubber industry, the compression ratio of different extruding machine can be used to unmasticated natural rubber of different materials. Compression extrusion machine than some different. [edit this paragraph] the principle of extrusion molding material since the bucket into the barrel, the screw rotates under the action of the cylinder wall and the surface of the screw friction shearing forward delivery to the feeding section in the loose. Forward transport also is compacted; the compression section, screw groove depth, further compaction, while the barrel heating and screw and cylinder wall friction shear, the material temperature rise began to melt, the compression section ends; homogeneous section material uniform, constant temperature, fixed quantity, squeeze out to melt. After a head forming, by setting the product.

- Q:Before and after the original good tune, up and down again before and after the tune, before and after, and up and down again

- The nose is not accurate enough or wornOr the screws are not screwed in placeOr die inappropriate, too large

- Q:the machine vibration is great, the motor, reducer are checked, no problem, there is abnormal sound.

- Is the fitting of the moving parts normal?.Is there an impact on the extrusion chamber?.

- Q:Why is the connection between the extruder and the switchboard?. The upper and lower three terminals are short circuited

- The action should be to require three simultaneous electricalOr a two way backup

- Q:What are the two types of extrusion?

- Extrusion? The extruder. The extruder is divided into single screw extruder and twin screw extruder, and the twin screw extruder is divided into two parts: flat, double and cone.

- Q:Extruder price

- According to the size of the screw, single and double screw configuration is different, there are many different prices between fifty thousand to two hundred thousand, we specialize in the production of extruders, crushers and mixing machines, high quality and low price, contact information on the user name

- Q:why production is not strong?I have several new co extrusion machines, but the blown plastic bags are not produced by others

- Plastic tensile testing without tension is strong that said, you should be the low tensile strength, tensile strength for 2 kinds of films, one is the transverse tensile strength, a longitudinal tensile strength, is a reflection of the tensile properties, the tensile strength of the plastic bag if you low, because your choice of materials is not brittle material or toughness (PE/PP/PVC/PET/PBT/PC do not know or what material) if you insist on using this material, make plastic bags, you can modification method by crosslinking, adding additives, improving formula, to achieve the goal, the specific situation you need to find a degree in Polymer Science plastic engineer, they will tell you.

- Q:Basic parameters of extruder screw

- 1, screw diameter Ds screw diameter is the diameter of the thread, the extruder production capacity (extrusion amount) is approximately proportional to the square of the diameter of the screw and, under the same other conditions, the screw diameter increases a little, significant increase will cause extrusion amount, the effect was even greater than the effect of the increase of screw speed on the extrusion rate is high. Therefore, the screw diameter is used to characterize the specifications of the extruder.

- Q:Why? What is the raw material of plastics? What is the process flow of the process?.

- It must be injection, you see that hole, that button, can not squeeze out.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic PVC Pipe Making Machine Extrusion Type

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords