Plastic/Ployester/Fiberglass Geogrid Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Geogrid Description

Geogrid with high strength steel wire (or other fiber), through special processing, and polyethylene (PE) or polypropylene (PP), and adding other assistants, by extrusion into composite type high tensile belt, and the surface is rough textured, for high strength reinforced geotextile strips.

2. Geogrid Applications:

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

3. Geogrid Properties

High stength,small deformation, homogenous stucture, easy for constrution etc.

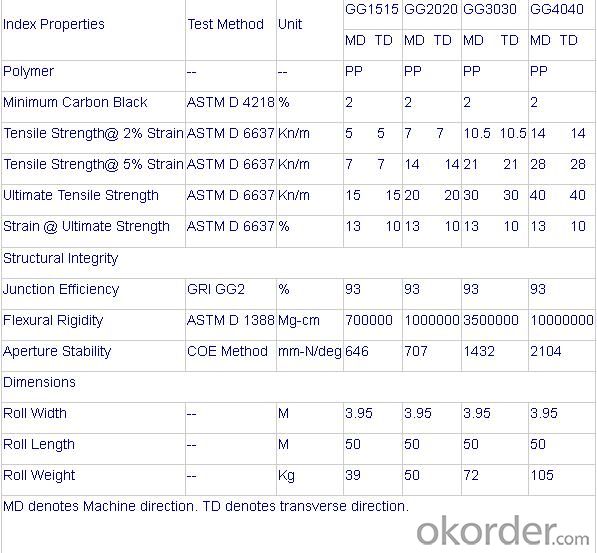

4. Geogrid Specification

FAQ:

Q:How about the delivery time?

A:Lead time since receipt of 30% T/T deposit payment: 3 weeks.

Q:What kind of payments does jenor support?

A:T/T, L/C, Cash are accepted.

Q:What's are the MOQ?

A:We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

Q:Do you charge for the samples?

A:Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee If you set the order .

Q:Can you produce the product according to customers' requirements ?

A:Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q:Are geogrids suitable for use in vegetated slopes?

- Yes, geogrids are suitable for use in vegetated slopes. Geogrids provide reinforcement to the soil, helping to prevent erosion and improve stability in sloped areas. The open structure of geogrids allows for vegetation to grow through, promoting the establishment of plants and enhancing the overall aesthetics of the slope. Additionally, geogrids can help to distribute the load and reduce the stresses on the soil, thereby increasing the lifespan of the vegetated slope.

- Q:Can geogrids be used in mining and geotechnical applications?

- Yes, geogrids can be used in both mining and geotechnical applications. Geogrids are commonly used in mining to reinforce soil and rock slopes, stabilize excavations, and provide support for haul roads and mine walls. In geotechnical applications, geogrids are used to reinforce soils, increase slope stability, and improve the performance of retaining walls, embankments, and foundations.

- Q:What is the recommended geogrid aperture size?

- The recommended geogrid aperture size depends on various factors such as the type of soil and the intended application. It is best to consult with a geotechnical engineer or refer to specific industry standards and guidelines to determine the appropriate geogrid aperture size for a given project.

- Q:Are geogrids suitable for use in mechanically stabilized retaining walls?

- Yes, geogrids are suitable for use in mechanically stabilized retaining walls. They are commonly used as reinforcement elements in these types of structures to enhance their stability and increase their load-bearing capacity. Geogrids help to distribute the lateral earth pressures more evenly, reducing the risk of wall failure and providing long-term stability.

- Q:Are geogrids suitable for reinforcement of mechanically stabilized aggregate layers?

- Yes, geogrids are suitable for reinforcement of mechanically stabilized aggregate layers. Geogrids are designed to enhance the load-bearing capacity and stability of soil or aggregate layers. They can effectively distribute and transmit load forces, improving the overall performance and longevity of mechanically stabilized aggregate layers.

- Q:Do geogrids provide reinforcement to geosynthetic asphalt liners?

- Yes, geogrids can provide reinforcement to geosynthetic asphalt liners. Geogrids are typically used to enhance the stability, strength, and performance of geosynthetic materials, including asphalt liners. They help distribute loads and reduce stress, improving the overall durability and longevity of the liner system.

- Q:What is the meaning of 400g geotextiles /100g woven fabric

- Main production, geotextile, geogrid, geomembrane

- Q:Can geogrids be used in railway construction?

- Yes, geogrids can be used in railway construction. Geogrids are commonly used to reinforce the soil and provide stability in railway tracks. They help distribute the load and prevent lateral movement of the ballast, increasing the longevity and performance of the railway infrastructure.

- Q:Are geogrids suitable for use in slope stabilization for mining tailings dams?

- Yes, geogrids are suitable for use in slope stabilization for mining tailings dams. Geogrids provide reinforcement and stability to the slopes, preventing erosion and potential failure of the dam. They are designed to withstand high loads and are effective in controlling soil movement, making them an ideal solution for slope stabilization in mining tailings dams.

- Q:Is there a geogrid in the transition section of Railway

- He is mainly a connection and prevent sinking

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic/Ployester/Fiberglass Geogrid Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords