PLASTIC INJECTION MOLDING MACHINE-C SERIES

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 SET unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PLASTIC INJECTION MOLDING MACHINE-C SERIES

General Description of PLASTIC INJECTION MOLDING MACHINE-C SERIES

Reliable plastic injection machine with servo motor, equiped with or without servo motor , closed loop control for pressure and flow. Low noise, high precision and energy saving.

We design,manuafcture and supply our own brand of injection molding machine with clamping force ranged from 600kn to 16800kn, injection weight from 80g to 10000g, and also provide custom-built machine.

They can produce all kinds of plastic parts, bottle preform, engineering plastic, UPVC, PVC, PE pipes fitting, components for automotive, household, electronics, telecommunication, ETC

Advantage of PLASTIC INJECTION MOLDING MACHINE-C SERIES

1. NUMBER CONVE RSION LINKAGE STRUCTURE

N purpose of keeping lock shaft on platen non-rotated, we convert connecting rod number. In that way, the loss of platen and the future ma-intenance cost of customer decline effectively, at the same time, it protects the crucial components.

2.HIGH STRENGTH FRAME

Base on finite element modeling, use whole bending process, substantially enhance the frame’s rigidity, reasonable tie bar distribution, and the machine running stability be increased.

3. DOUBLE MOVABLE HYDRAULIC CYLINDERS TIGHTENING STRUCTURE

Two parallel movable hydraulic cylinders pull injection table to tighten nozzle and mold. It eliminates oblique torque when single cylinder is tightened, diminishes deformation of screw and barrel, meanwhile, it extends life of screw and barrel, optimizes plasticizing effect.

4. INJECTION PREPLASTICATION SEAT WITH OIL COPPER SLEEVE

The preplastication seat reciprocates once in every injection motion. Normal non-automatic lubrication in injection unit can't offer lubrication support to this important motion. Thus, we use oil copper sleeve to make sure that injection reciprocates well. Even without lubricating oil support, it can also slide excellently.

Considering cost, however, some materials without oil always cause hamful effect to injection accuracy after a period of time.

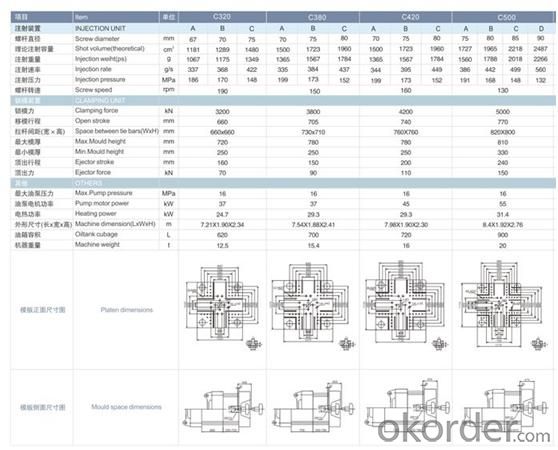

Specification of PLASTIC INJECTION MOLDING MACHINE-C SERIES

Package of PLASTIC INJECTION MOLDING MACHINE-C SERIES

Wooden box packed, suitable for train or sea worthy delivery.

FAQ:

1. Why Choose us?

CNBM is a stated owned company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

3. Can you provide sample?

Yes, we can offer free sample for you.

4. Payment terms?

We can accept L/C, T/T etc.

5. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q:Plastic blank in the gear hobbing machine processing, hob and workpiece is not to heat, then plastic is not easy to stick on the machine body.Just want to know the plastic gear processing technology is how, and ordinary steel gear processing technology difference where?.The more detailed, the better. Thank you

- Plastic gear direct injection molding, generally do not require posterior processingNow there are new processes, such as two injection molding, etc.

- Q:I'd like to open a plastic bag factory. How much do I need to buy the equipment?

- It depends on what plastic bags you need to make, and the size and size of the big plastic bags are also crucial. I make plastic bags.

- Q:The processing of plastic bottles

- The production process of plastic bottle has two kinds: the first kind is extrusion blowing process, the plastic raw materials into the extruder, the melting extruding molten parison, then put the bottle mold blow molding, cooling after removed from the mold, eliminating waste edge to be finished after. This process is mainly used to produce polyethylene, PVC plastic bottles, such as milk bottles, soy sauce bottles and so on. The second is the plastic material injection stretch blow molding process, the injection molding machine injection molding tubular billet, then put the bottle mould through stretch blow molding, cooling after the finished product is obtained. This process is mainly used to produce PET plastic bottles, such as mineral water bottles and so on.

- Q:Laizhou plastic processing plastic machinery and equipment, which is more reliable, relatively good?

- In contrast to many manufacturers of plastic processing equipment, more important is environmental protection, there is calm in the future, if you want to buy the equipment you can go to Laizhou city to take a look at the field, there are a lot of home doing well, you have this problem too vague, but also do not know you to play some bottom in figure what product, change a problem to try again

- Q:where there are advanced environment-friendly recycled plastic processing equipment?

- Environmental protection recycling plant, this is a systematic project, the use of granulation machine is usually used granulator, need to be matched with waste water filtration, sedimentation, purification treatment pond, waste gas purification equipment.

- Q:What kind of equipment do you need for the food market? How much would you like to invest? What about the profit?

- The first said equipment 1 blowing machine 2 printing machine 3 bag making machine 4 mill material if want to make your own words also need about 27000 granulating machine, film blowing machine, printing machine if printing a color around 10 thousand, if 2 more than 20000 more than 20000 color printing, bag making machine semi-automatic, fully automatic ranging from 4-5 million, 3500 mill more than 20000, granulator, raw materials are polyethylene, if the price of raw materials is a new material price 11000 tons, if it is recycled about 7000 of us production of complete sets of equipment

- Q:What kind of equipment does the plastic product factory need?

- Like universal printer, you can achieve this effect. In some plastic shell, plastic, plastic stationery and other top brands.

- Q:I don't know what kind of machine is needed. How can I sell the material after processing? Is there anyone?I want to make a waste plastic (plastic bottle) small processing at home, I don't know what kind of machine is needed. How can I sell the material after processing? How much money does it cost?. Seek expert advice, the more detailed, thank you!

- Friends probably want to make plastic crushing factory! General plastic bottles, such as mineral water bottles, PET, detergent, milk bottles, etc.

- Q:What equipment? How much money do not.. at first. There are several sets of injection molding machine can be about 2... Mainly plastic injection molding. The ABS PA PE PP PVC... Etc. in this area. Please know that a friend told Kazakhstan. Thank you.

- Do PVC also dedicated screw, because PVC easily decomposed, and after the decomposition of the cylinder, screw, as well as mold are corrosive. Other material requirements are not high, so when you buy the machine, you must tell the manufacturer of your material.Equipment needed:1. injection molding machine2. pumps {pumps cooling machine mold, two units, the single-phase can be}

- Q:I want to make some plastic products. Thank you。 FiveThe four type: first, a one or two meter long, hard, but bent plastic tube. Then there's something like the front end of the syringe. And then a small plastic kettle. Finally, a small thing that can be secured to the mouth of the pipe.

- Second similar things syringe I suggest: as long as you can find a think suitable syringe or other similar things, then take it to the more small machinery plant hopes to solve the problem (fourth questions refer to the answer); two cases of third problems, as long as one or several that simply.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PLASTIC INJECTION MOLDING MACHINE-C SERIES

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 SET unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords