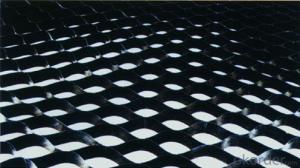

Plastic Grid Used for Car Parking & Lot Grass Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1,Description of Plastic Grass Grid used for Lot Grass Protection

Nature Planting grass grid using modified high molecular HDPE as raw materials , Green and Environmental Protection , Completely recyclable , it can perfect realize to combine the lawn and parking lot,it can bear pressure , abrasion resistance, impact resistance, antiaging, corrosion resistance , improve the quality , and save the investment; unique flat plug type overlap joint , can adjust expansion joint .

Material : Modified high molecular HDPE , Fiberglass , Nanometer oxide , Coloring Material ( standard ratio) .

Color : green color or other any specified color

Bearing capacity : The hightest 200T/m2

2,Specialities of Plastic Grass Grid used for Lot Grass Protection

1) Fully green grass, provides more than 95% planting grass area, completely greening effect , can sound-absorbing, vacuuming, significantly improve the environmental quality and taste.(Reference: concrete planting grass brick only 30% interspace )

2) Saving the investment .

3) Nature Planting grass grid can perfect realize to combine the parking and greening . In land-scarce city , it can save developers valuable investment .

4) Leveling , neat,

5)Unique and stable flat plug type overlap joint make the whole pavement surface as the flat entirely , avoid part place sinking , so the construction is very convenient .(Reference: concrete planting grass brick is independent each one , it must be pouring concrete foundation layer , so can keep flat and integrity ) .

3, Application of Plastic Grass Grid used for Lot Grass Protection

Parking lot , Fire fighting access , Fire fighting high surface , Golf lane , Conference and exhibition center , Modern workshop , Upscale community , Roof garden and so on .

4,Construction suggestions:

Foundation soil should be compaction as different layers , Compactness should be reach more than 85% .

Gravel bearing should be paved 350 thickness (Fire lane should be 600 thickness) , spread out to flat and grind to compaction .

Gravel or coarse sand should be paved 20thickness .as the flat layer .

Pave and install grass grid can be cut to suitable size by saw , and you should leave a few millimeters slit between grid and grid .

Sowing planting soil on the grid surface from the top about 1.0cm

Lay down in grass or sowing grass seed . While lay down in grass , .turfing has to be compacted , watering and maintaining , you can park car when grass grow .Protecting lawn .

Gravel bearing layer can supply some store water function , this is beneficial for lawn grow , grass roots can grow to gravel layer .(Reference: concrete planting grass brick only has small space , and when under summer sunshine , temperature will reach more than 50 °C ) .

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of construction materials, including but not limited to PP staple fiber, geotextile geo-grid, geo-bag etc. Customized product is also available based on your detailed requirements.

2>How long can we receive the product after purchase?

It takes about 1 to 4 weeks to finish the production based on the specific production schedual. Then it will depend on the shipping time from loading port to the destination port.

- Q:Concrete panel shop asphalt do not add geotextiles

- Plus no geotextile cloth according to the design requirements and construction specifications. Generally require high road construction need to lay geotextile. Geotextile manufacturers to answer your questions

- Q:Geotextile with glue can stick cement wall

- With the wind oil fine soaked, wipe with a rag off.

- Q:What are the specifications for geotextiles in athletic field construction?

- The specifications for geotextiles in athletic field construction may vary depending on the specific requirements of the project. However, some common specifications include the material type, strength and durability, permeability, and installation requirements. Geotextiles used in athletic field construction should typically be made of high-quality synthetic materials like polypropylene or polyester, ensuring adequate strength and resistance to tearing, punctures, and UV degradation. The permeability of the geotextile is essential to allow for proper drainage and prevent water accumulation, which can affect the field's performance. Additionally, the installation requirements may include recommendations for overlap and seaming techniques to ensure proper integration with other field components.

- Q:What are the cost considerations for geotextiles?

- The cost considerations for geotextiles depend on various factors such as the type and quality of geotextile required, the size and complexity of the project, and the supplier or manufacturer chosen. Generally, the cost of geotextiles includes the product cost, transportation and delivery charges, installation expenses, and any additional materials or equipment required. It is important to carefully evaluate and compare prices from different sources to ensure the best value for money while meeting the project's specific needs.

- Q:What are the potential drawbacks of using geotextiles?

- Some potential drawbacks of using geotextiles include the high cost of materials and installation, limited durability in certain environments, potential for clogging due to fine particles, and difficulty in recycling or disposing of used geotextiles. Additionally, improper installation or selection of geotextiles may not provide the desired results, leading to project failure or inefficiency.

- Q:Are geotextiles resistant to fire damage?

- Yes, geotextiles can be resistant to fire damage. Many geotextiles are specifically designed to have fire-resistant properties, which help prevent them from igniting or spreading flames. However, it is important to note that the level of fire resistance may vary depending on the specific type and composition of the geotextile.

- Q:How are geotextiles used in erosion control?

- Geotextiles are used in erosion control by providing a protective barrier against soil erosion. They are placed on the ground surface or buried within the soil to prevent or minimize the loss of soil particles due to water flow or wind. Geotextiles help stabilize the soil by improving its strength and reducing the movement of sediments, thus preventing erosion from occurring.

- Q:Where to sell waterproof geotextile

- Hello, waterproof geotextile is a composite geomembrane if necessary to the Department of Huazhi geotextile material manufacturers to answer the beginning of 135, 4791 last 9192, do not forget Oh

- Q:How do geotextiles help with reinforcement of geotextile tubes?

- Geotextiles help with the reinforcement of geotextile tubes by providing additional strength and stability. They act as a barrier between the soil and the tube, preventing soil erosion and maintaining the integrity of the structure. The geotextiles distribute the load evenly and reduce the risk of punctures or tears in the tube, thereby enhancing its overall performance and longevity.

- Q:How are geotextiles maintained?

- Geotextiles are typically low-maintenance materials that require minimal upkeep. However, to ensure their longevity and effectiveness, geotextiles should be regularly inspected for any signs of damage or degradation caused by environmental factors or heavy loads. If any issues are identified, appropriate repairs or replacements should be carried out promptly. Additionally, periodic cleaning may be necessary to remove any accumulated debris that could potentially hinder the geotextile's performance. Overall, proper maintenance of geotextiles involves routine inspection, timely repairs, and occasional cleaning to preserve their functionality and lifespan.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic Grid Used for Car Parking & Lot Grass Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords