Plastic Grass Paver Geocell Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Plastic Grass Paver Geocell:

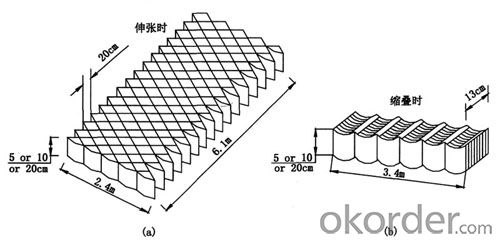

High Quality HDPE Plastic Gravel Stablizer / Soil Stabiliser Geocell is made from HDPE (high-molecular polyethylene) with fiber and age resistor,using high pressure to inject plastic to form bee nest-like shaped shell, with stereo space and support level. It's widely used in parking lot, fire exit, fire climbing surface, pavement etc. Since it can protect the grass, it is also known as the green grass protection mat.

Main Features of Plastic Grass Paver Geocell:

to stable the bed of railway and road

to bear the bed of road

to bear the loading dykes and walls

to administer shallow water and river

to support pipeline and sewer

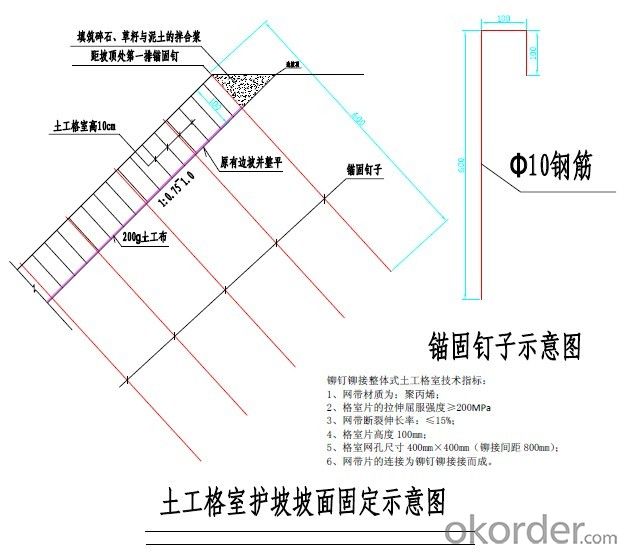

to prevent landslide and to be used as compound walls to support loading

to be used in dependent walls,wharfs and bank and so on

to govern sand,beach,river bank and riverbed

Specifications of Plastic Grass Paver Geocell:

Geocell welding mold-digit | HJM-11 | HJM-14 | HJM-15 | HJM-18 | HJM-22 |

No.of welding heads | 11 unit | 14 unit | 15 unit | 18 unit | 22 unit |

Max. Power | 28.6KW | 36.4KW | 36.6KW | 46.8KW | 57.2KW |

Ultrasonic Vibrating Power | 16.5KW | 21KW | 23KW | 27KW | 33KW |

SIZE OF THE EQUIPMENT (L*W*H)(M | 6.5*1.89*2.26 | 7*1.89*2.26 | 8*1.89*2.26 | 8*1.89*2.26 | 9*1.89*2.26 |

WEIGHTNESS | 5TONS | 5.5TONGS | 5.8TONS | 6TONS | 6.5TONS |

POWER | AC380V N 50-60HZ | ||||

AIR PRESS | 0.6~0.9MPa | ||||

AIR COMPESSOR DISPLACEMENT | ≥2.5~3.0/min | ||||

VOLOUM OF AIR COMPRESSOR AIR STORAGE | 1.5~2.0M3 | 2.5~3.0M3 | |||

WELDING DISTANCE SCOPE | 220-1000mm | ||||

GEOCELL STRIP WIDTH | 220MM MAX (ADJUSTABLE ACCORDING TO THE SIZE OF WELDING HEAD) | ||||

DAILY OUTPUT (REF) | 4500SQM | 4800SQM | 5000SQM | 5200SQM | 8000SQM |

IMages of Plastic Grass Paver Geocell:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q:200g geotextile how much money a square

- Geotextile laying - including the labor costs (according to geotextile specifications and laying conditions and requirements are different), material costs (specific quality requirements and thickness, are not the same ..), mechanical use costs (such as transport, sewing System, hoisting, etc.). The price is different. Sometimes the construction of our geotextile laying, the price per square meter from 9 yuan to 50 yuan range.

- Q:Such as the title, the drawings are written on the weaving geotextile, the list is written on the blended geotextile cloth laying / 120g / m2 weaving geotextile, who can tell ah !!!!!!!!!! Urgent more

- Weaving geotextile cloth, also known as woven geotextile, and non-woven geotextile is not the same, the technical requirements between them are not the same. Light to see the material name sometimes can not determine the material, mainly to see the technical data, if you want to know more about it can add me

- Q:How are geotextiles recycled?

- Geotextiles can be recycled through a process called mechanical recycling. This involves collecting used geotextiles, cleaning them, and breaking them down into smaller fibers or pellets. These recycled materials can then be used to manufacture new geotextiles or other products, reducing the need for raw materials and minimizing waste.

- Q:How do geotextiles help with reinforcement of steep slopes?

- Geotextiles help with the reinforcement of steep slopes by providing stability and preventing erosion. They are placed within the slope to act as a barrier, holding the soil in place and preventing it from sliding or washing away. Geotextiles also allow for water drainage, reducing the chance of saturation and further erosion. Overall, they enhance the strength and durability of steep slopes, making them more resistant to natural forces such as gravity and rainfall.

- Q:What are the geotechnical test test items for highway engineering? The

- The main inspection items are: ① Tensile strength: In the tensile test, the maximum tensile stress of the specimen up to the fracture is the tensile strength, which is called tensile strength in academia. ② elongation: elongation, that is, the percentage of the ratio of the total deformation to the length of the original gauge after the tensile fracture of the specimen. ③ tear strength: it is a thin film or thin film tear resistance of a test method defined in a term. This method is a tear test performed on a special testing machine with a specimen with a predetermined gap. ④ bursting strength ⑤ thickness ⑥ per unit area quality ⑦ permeability coefficient: permeability coefficient, also known as hydraulic conductivity. In an isotropic medium, it is defined as the unit flow rate per unit of hydraulic gradient, indicating the ease with which the fluid passes through the pore skeleton.

- Q:Construction Method of Sand and Gravel Cushion on Slope Soil Geotextile

- Online to find some relevant construction methods, Google library on a lot. After downloading, modify, targeted to add that is the slope of geotextile sand and gravel cushion construction method.

- Q:How are geotextiles used in civil engineering projects?

- Geotextiles are commonly used in civil engineering projects for various purposes such as soil stabilization, erosion control, drainage management, and filtration. These synthetic fabrics are placed in the soil to reinforce it, prevent erosion, filter water, separate different layers of soil, and improve the overall performance and longevity of the project. They are versatile, cost-effective, and environmentally friendly solutions that help enhance the stability and functionality of civil engineering structures like roads, embankments, retaining walls, and landfills.

- Q:What are the different geotextile installation techniques for erosion control blankets?

- There are several geotextile installation techniques for erosion control blankets, including trench and backfill, stake and tension, and anchor and pin. Trench and backfill involves digging a trench along the slope, placing the erosion control blanket in the trench, and then backfilling it with soil. Stake and tension involves driving stakes into the ground at regular intervals and then securing the erosion control blanket to the stakes with tensioning devices. Anchor and pin involves using anchors or pins to secure the erosion control blanket directly to the ground. The specific technique used depends on the slope conditions and project requirements.

- Q:Can geotextiles be used in green wall systems?

- Yes, geotextiles can be used in green wall systems. Geotextiles are often used as a filtration and separation layer between the soil and the retaining structure in green walls. They help retain moisture, prevent soil erosion, and provide stability to the system.

- Q:What are the factors affecting the performance of geotextiles?

- There are several factors that can affect the performance of geotextiles, including the type of material used, the manufacturing process, the installation method, the environmental conditions, and the design considerations. The strength, durability, and permeability of the geotextile, as well as its ability to withstand chemical and biological degradation, play a significant role in its performance. Additionally, factors such as soil characteristics, loading conditions, and the presence of water or chemicals can also impact the performance of geotextiles. Proper selection, installation, and maintenance are crucial in optimizing the performance and longevity of geotextiles.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic Grass Paver Geocell Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords