Plastic Formwork Concrete Formwork Parts Tubular Scaffolding Scaffolding Importers Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

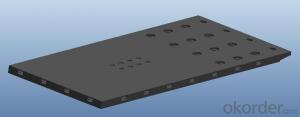

Plastic Formwork Concrete Formwork Parts Of A Tubular Scaffolding Scaffolding Importers Low Price

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

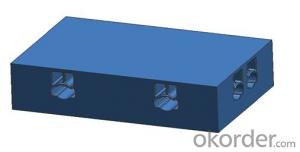

2.Easy set up

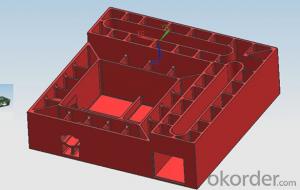

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

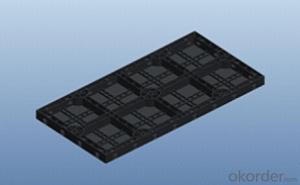

3.Modularity

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels of multiply by 125px. The material of modular formwork is PC-ABS mixed with special glass fibers which enable panels to hold high pressures.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

FAQ

We have organized several common questions for our clients, may help you sincerely:

1)How is the Packaging Details?

In bags or as the requirement ofcustomers.

2)How long can we receive the product after purchase?

Lead time is about 30days after getting the signed PI and deposit.

- Q:Plastic building template made of what material

- Template template, as the name implies, is a model (you can think so), and the building template is in the construction of the project, before making the actual product, according to the design pattern, according to the data, such as component dimensions and other related ghosts , To produce a model consistent with the design specifications, and the production of this model is the template material

- Q:I am a novice, do this product development, and now design a set of products, and now take the product to open the mold, it is not clear what kind of material template selection! Please advise experts who look

- Is the template based on your product requirements, can you talk about the requirements of each part of your product?

- Q:How does the concrete on the plastic template remove (already glued to the concrete)

- With pliers slowly pull, or spray gun spray.

- Q:Want to purchase a number of building templates and found a new plastic building template, do not know how the quality?

- Why can not, now the plastic template, called light building materials, China is not yet a few plants can do a good job, after the air-conditioning refrigerator to use this, light and hard, not you like this, you can do with the wall, Now high-end are imported.

- Q:We have to start the construction site immediately, and have not used this plastic building template; I would like to ask you all the big brother who used this plastic building template ah? How is the quality of ah? So good ah?

- Plastic mold is better, light weight, high impact strength, easy assembly, high turnover rate, smooth surface, no moisture, no mildew, Naisuan Jian, no cracking, large plate, less joints, can be saw, can Nail, can be processed into any length and so on

- Q:Plastic deformation of the template how to solve or why the deformation Thank you I want the reason

- The lower the density of the foam board is easier to deform.Crust foam can be changed to coextrusion foam. General cross-linking or blending halogenation and other methods to improve Vicat. Reduce traction override

- Q:Europe and the United States national construction template is made of plastic or wood

- Part of the place with stones, as the case may be, but certainly yes, Europe and the United States have anti-seismic buildings

- Q:Why the floor is not plastic building materials square wood and template

- Is the plastic strong? The environment on the site you know, throw off how to do, have to find strong and durable.

- Q:Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- Plastic template this line, and now China is not perfect, may reach less than 30-50 this requirement, but better than the wood template, fire requirements should be able to achieve.

- Q:Types of building templates? What is the water template?

- The type of template, according to the material to wood template, steel formwork, bamboo template, Gangmu combination template, etc.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic Formwork Concrete Formwork Parts Tubular Scaffolding Scaffolding Importers Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords