Plastic Color Masterbatch for Injection Molding, Wire Drawing, Extrusion Craft

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Color masterbatch is made of inorganic and organic pigment,dye and suitable additives auxiliaries.

Widely used for Packing film, bottle,cap,hose,all kinds of containers as well as toys, household appliance,office supplies , building pipe, ect.

Advantage of Color Masterbatch:

1.This series color masterbatches are of high concentration pigment with bright colors.

2.When they are used in resins, it shows better dispersing and stablility performance.

3.Also the mixture has the highest mechanical intensity preservation rate.

4.A broad standard color range available from stock as well as tailor made products develop according to customer requirements.

Features of Color Masterbatch:

-Standard, universal, or custom colors

-Carriers optimized for easy processing

-Production orders shipped in 5 days

Additive amount:Compound masterbatch and resin with 1:25--50 uniformly (according to the products requirements).

It can be used after drying

Application:Blow molding, Injection molding, wire drawing, extrusion craft.

Packaging:Paper-plastic compound bags,or PE bags,25kg net weight/bag.

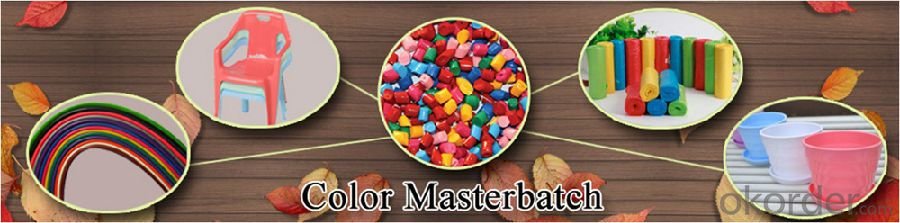

Product Pictures of Color Masterbatch

- Q:Is the plastic with high melting index good?

- Its test method is: first let the plastic particles in a certain time (10 minutes), under certain temperature and pressure, melt into plastic fluid, and then through a diameter of 2.1mm tube g (grams) outflow. The greater the value, the better the processability of the plastic material, the worse the contrast.

- Q:Low pressure plastic raw materials in the process of blowing the two sides of the fold, how to deal with?

- Blow up ratio of transverse expansion ratio of the film, is actually on the orientation of the transverse tensile film, tension will have a certain degree of plastic molecules, the blowing ratio is increased, thereby improve the lateral strength of thin films.

- Q:What is the plastic basin made of?

- The raw material is PP and PE, the raw material price is more than 10000, and some can be recycled at around 5000.

- Q:What material is the disc made of, metal or plastic?

- In general, the substrate is colorless and transparent polycarbonate board, in the entire disc, it is not only the carrier of the groove, but also the physical shell of the whole cd.

- Q:What is the plastic bag made of?

- Method for identification of toxic plastic bags. The water detection method: put a plastic bag into the water, non-toxic can be surfaced, and poisonous won't rise; hand touch detection method: white or colorless transparent is non-toxic, the hand has a sense of lubrication, the surface like wax; color detection method: toxic haze or color yellow, red, black, feel sticky; jitter method: take a plastic bag shaking, crisp sound non-toxic; sound stuffy astringent toxic.

- Q:PE plastic bellows raw material formula (PE and PP ratio, as well as other filling)?

- PP and PE plastic corrugated pipe in the role of the following two: 1, PP material can reduce the production of pipe, HDPE than PP pipe grade market sales price higher, the production of HDPE pipeline adding appropriate amount of PP, for the reduction of raw materials

- Q:What are the main biodegradable plastic bags made of?

- Biodegradable plastics(1) natural polymer modification method. Starch, cellulose, chitin, lignin, seaweed and other natural polymers as raw materials, through chemical modification and copolymerization method, these molecules were modified to synthesize biodegradable plastics.(2) chemical synthesis. The simulation of natural polymer structure, starting from simple water molecules, in the polymer chain of plastic with active groups such as amide, peptidyl, ester compounds containing these radicals, similar to natural protein structure, fragments of grease, easily biodegradable.(3) microbial fermentation, many microorganisms can take some organic substances as carbon source, through metabolism, secrete, produce polyester polymer, these molecules are easy to degrade, and can be further recycled.

- Q:Raw materials for making plastic bags

- For the identification of PVC plastic bags and polyethylene plastic bags, the following simple methods are used for identification. Polyethylene film (non-toxic) film is milky white, translucent (a few stacked observation especially), feels like a lubricant is coated on the surface of a layer of wax, shaking, crisp sound, fire flammable, flame yellow, burning mucus dripping, and the candle burning smell.

- Q:What kind of material is the raw material of plastic pipes?

- Plastic pipe raw material is plastic particles, according to the pipeline production processing performance requirements, with the different requirements of finished products, there are different manufacturers grades, grades and performance differences.

- Q:That kind of plastic bottle blows well

- PETA hard, tough, high strength, bright surface with transparent and multi colored sheets. The disadvantage is PET high frequency synthesis is difficult, the price is a bit more expensive than PVC, this material is often high-grade products and environmental requirements of the user to replace the PVC PET material generally used to make packaging for food, beverage, pharmaceutical plastic bottles.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic Color Masterbatch for Injection Molding, Wire Drawing, Extrusion Craft

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords