Plastic Biaxial Geogrid for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1. Description

Plastic biaxial geogrid with high strength steel wire (or other fiber), through special processing, and polyethylene (PE) or polypropylene (PP), and adding other assistants, by extrusion into composite type high tensile belt, and the surface is rough textured, for high strength reinforced geotextile strips. The single band, the longitudinal, transverse certain space preparation or clamping arrangement, with special reinforcement welding technology welding the connection point bonding and molding, is reinforced with Geogrid.

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

3. Properties

High stength,small deformation, homogenous stucture, easy for constrution etc.

FAQ:

Q:How about the delivery time?

A:Lead time since receipt of 30% T/T deposit payment: 3 weeks.

Q:What kind of payments does jenor support?

A:T/T, L/C, Cash are accepted.

Q:What's are the MOQ?

A:We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

Q:Do you charge for the samples?

A:Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee If you set the order .

Q:Can you produce the product according to customers' requirements ?

A:Sure, we are professional manufacturer, OEM and ODM are both welcome.

Plastic biaxial geogrid with high strength steel wire (or other fiber), through special processing, and polyethylene (PE) or polypropylene (PP), and adding other assistants, by extrusion into composite type high tensile belt, and the surface is rough textured, for high strength reinforced geotextile strips. The single band, the longitudinal, transverse certain space preparation or clamping arrangement, with special reinforcement welding technology welding the connection point bonding and molding, is reinforced with Geogrid.

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

3. Properties

High stength,small deformation, homogenous stucture, easy for constrution etc.

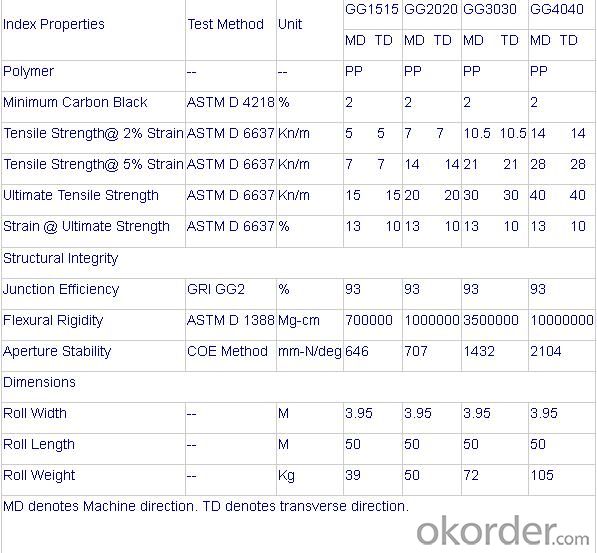

4. Specification

FAQ:

Q:How about the delivery time?

A:Lead time since receipt of 30% T/T deposit payment: 3 weeks.

Q:What kind of payments does jenor support?

A:T/T, L/C, Cash are accepted.

Q:What's are the MOQ?

A:We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

Q:Do you charge for the samples?

A:Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee If you set the order .

Q:Can you produce the product according to customers' requirements ?

A:Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q:What is a one-way plastic geogrid

- Uniaxial plastic geogrid is a high strength geosynthetics, with high density polyethylene (HDPE) as raw materials, pressure into a sheet by extrusion and punching network rules, and then the longitudinal stretch into the geogrid, widely used in dam, tunnel, highway, railway, port, construction etc. field

- Q:One-way plastic geogrid TGDG120 how qualified

- One way plastic geogrid is mainly used in Subgrade Reinforcement Engineering

- Q:Construction technology of steel plastic grille

- (4) the first layer of geogrid paved, began to fill with second layers of 0.2m in thick sand (coarse), the method of sand transport to the site: car unloading to the subgrade side, then put forward to push the bulldozer, within 2 meters on both sides of the subgrade filling after 0.1M, the first layer of geogrid fold up and then fill in 0.1 meters in the sand (coarse), from both sides to the middle filling and advance, prohibit all machinery without filling (coarse sand) of Geogrid on traffic operation, it can guarantee the geogrid is smooth, does not play drums, do not wrinkle, stay in the second layer (coarse) after the formation of sand, the level of measurement, to prevent uneven filling thickness, leveling and correct use of vibratory roller 25T static pressure two times.(5) as the second layer of geogrid layer construction method with the first method, and finally filling in 0.3m (coarse sand), filling in the same way as the first layer, using 25T hydrostatic roller two times, so subgrade reinforcement is dealt with.

- Q:How do geogrids improve the performance of flexible pavements?

- Geogrids improve the performance of flexible pavements by enhancing their stability, reducing rutting and cracking, and increasing their overall lifespan. They act as a reinforcement layer within the pavement structure, distributing and transferring the load more efficiently. This helps to minimize pavement deformations and increase resistance to fatigue and shear stresses. Geogrids also restrain the lateral movement of aggregate particles, preventing their displacement and improving the pavement's resistance to lateral spreading and cracking.

- Q:Are geogrids suitable for use in soil reinforcement for coastal protection structures?

- Yes, geogrids are suitable for use in soil reinforcement for coastal protection structures. Geogrids are commonly used in such applications as they provide effective reinforcement by distributing the loads and stabilizing the soil. They help to prevent erosion and improve the stability and durability of coastal structures, making them a reliable solution for coastal protection.

- Q:Can geogrids be used in reinforcement of gabion walls?

- Yes, geogrids can be used in the reinforcement of gabion walls. Geogrids are commonly used to enhance the stability and strength of various types of retaining walls, including gabion walls. By placing geogrids within the gabion structure, the walls can withstand higher loads and provide better resistance against soil erosion and lateral forces.

- Q:Are geogrids suitable for coastal engineering projects?

- Yes, geogrids are suitable for coastal engineering projects. They are commonly used to reinforce and stabilize coastal structures such as seawalls, breakwaters, and revetments. Geogrids provide excellent soil reinforcement, preventing erosion and enhancing the stability of coastal structures in the face of wave action and tidal forces. Furthermore, their high tensile strength and durability make them ideal for withstanding the harsh marine environment.

- Q:What is the role of Geogrid

- 4, geogrid used to reduce the thickness of cushion, save cost.5, the geogrid can effectively isolate the seismic force transfer, and to enhance the seismic stiffness, strength and stability of the embankment has an important role

- Q:How do geogrids improve the performance of pavements?

- Geogrids improve the performance of pavements by providing reinforcement and stabilization. They help distribute the load more evenly, reducing stress and preventing cracks and rutting. Geogrids also enhance the pavement's tensile strength, increasing its overall durability and lifespan.

- Q:Can geogrids be used in landfill capping systems?

- Yes, geogrids can be used in landfill capping systems. Geogrids are often used as reinforcement materials in landfill capping systems to enhance stability, prevent erosion, and provide support to the soil cover. They are effective in mitigating potential issues such as differential settlement and slope instability, making them a suitable choice for landfill capping systems.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic Biaxial Geogrid for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords