Plain Foil for Pre-Insulated Insulated Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Plain Foil for Pre-Insulated Insulated Panel

1.Structure of Plain Foil for Pre-Insulated Insulated Panel

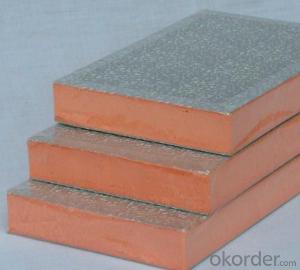

Air ductwork supply is pre-insulated aluminum panels constructed of both aluminum and Poly-isocyanurate. The sandwich panels are comprised of expanded Poly-isocyanurate rigid foam board, faced on both sides by aluminum foil.Ducting is the key part of any central air-conditioning system. It is similar in function to the arteries and veins in the human body as it helps in regulating the temperature in a building. The material used for making ducts for air-conditioning is constantly evolving in order to satisfy the demand for higher thermal efficiency, eco-friendliness, and increased energy savings. Many different materials and systems such as magnetite composite, PVC and so on have been developed as alternatives to the galvanized sheet metal used traditionally. But pre-insulated ducting materials is by far the most popular ducting system in use today. It is essentially a panel made with an insulating material such as PIR (Polyisocyanurate), PUR (Polyurethane) or Phenolic foam material sandwiched in between two layers of aluminium foil. Such a foam panel is easier than traditional galvanized sheet metal to manipulate for complex designs and lighter than its predecessors for installation. These qualities in addition to the fact that it has a much higher thermal efficiency than galvanized sheet metal make it an ideal material for fabricating Airconditioning ducts in harsh climates like the Gulf. Its application has been gradually extended to every type of air distribution system: industrial and commercial.

For construction of air ducting in HVAC systems, the Polyisocyanurate (PIR), PUR (Polyurethane) and/or Phenolic foam panel with 45kg/m3 density, coated with 80/80µm thick embossed aluminum foil have two panel types:

The air ducts fabricated using ALU 80/80 panels can be installed in plants:

with air speed up to 15m/s

with pressure up to 1000Pa

indoor

The air ducts fabricated by using ALU 80/200 panels can be installed in plants:

with air speed up to 35m/s

with pressure 1750Pa

outdoor

2.Main Features of Plain Foil for Pre-Insulated Insulated Panel:

Air Duct Panel / Pre-insulated Duct Panel / HVAC Duct Panel :

HVAC Aluminum Foil Duct Board

1. Be used for HVAC Duct system;

2. BS 476 Part 6&7 Class 0.

3. Low thermal conductivity.

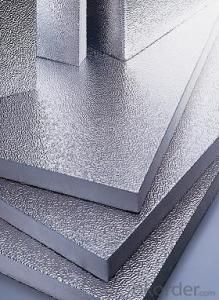

3.Plain Foil for Pre-Insulated Insulated Panel Images

Our embossed aluminum sheet/Coil series include:

1.diamond embossed aluminum sheet/Coil

2.orange peel embossed aluminum sheet/Coil

3.stucco embossed aluminum sheet/Coil

4.Plain Foil for Pre-Insulated Insulated Panel Specification

Air-conditioning Areas Exposed to weather

Thickness of panels 20 Mm 30 Mm

Thickness of aluminum 80/80 Microns 80/200 Microns

Density of the foam 44-48 Kg/m3 42-48 Kg/m3

Finishing of aluminum Embossed Embossed

Dimension Length: 4meter Width: 1.2meter

Note: Both sides of the aluminum foil are lacquered with a 3g/m2 weatherproof and ultraviolet ray protection polyester lacquer.

Certificate: FORM A, CO ,FORM E ,FORM B ,MTC, SGS and ROHS(client paid for it), MTC

Surface Quality: without any dent, scratches, oiliness , oxidation .

Chemicial composite and Machinary Property: Meet with GB/T, JIS,ENAW, ASTM standard

Month Capacity: 5000MT/month

exporting port: Tianjin, Shanghai

payment: TT or LC at sight

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How long for your delivery time?

Commonly 30 working days can be served. If you need the products urgently, we can shorten the delivery time into 20 days.

3. Where the Panels can't be used?

As extractors in the kitchen, as chimneys for smoke or chemical laden smoke

As transportation for solids

Outside temperature range -35ºC and +110ºC

Air speed >15m/s for 20mm thick panel and >35m/s for 30mm thick panel

when the negative or positive pressure inside the duct is: 20mm thick panel >1000Pa and 30mm thick panel >1750Pa

- Q:quot;A sample of aluminum chloride increased in temperature by 3.5 K when the sample absorbed 1.67 x 10^2 J of energyCalculate the number of moles of aluminum chloride chloride in this sample.quot;The molar hear capacity of aluminum chloride is 92.0 J/K molI don't know what the formula should be and what to put in, but I think it's q n C (change of temp.)

- d H n C dT 167 J n (92 j/mole)(3.5K) n 0.519 moles of AlCl3 which rounds to 0.52 moles

- Q:these cookies have coconut and oatmeal i dont remeber the rest

- 2 cups sugar 1 stick butter (1/2 cup) 1/2 cup Pet milk 1 teaspoon vanilla 2 1/2 tablespoons cocoa 1/2 cup peanut butter 3 cups oats In a medium saucepan, combine all ingredients except peanut butter and oats and cook over medium heatLet boil for 5 minutes, stirring constantlyRemove from heat and stir in peanut butter and oatsSpoon out quickly onto wax paper or aluminum foilCookies will harden as they set.

- Q:I want to know why they don't use Aluminum in piping for plumbing, it's supposed to be cheaper.?

- Edit Aluminum is not used for domestic plumbing primarily because it is much more expensive than threaded, galvanized steel and not as strongSch 40 CPVC threaded or solvent joint pressure piping is now especially preferrered for cold water and domestic hot water Along with galvanized pipe, copper tubing had been long preferred until costs and concerns with lead-based solders made copper unattractiveAluminum has not been popular except for a time a few decades ago when low cost put in into electrical wiring and possible into some limited small domestic pipingIt was and is used in thin wall , larger diameter low pressure industrial -type piping.

- Q:I have a 7ft long 2in wide aluminum tubeWould that be any good for making rail?

- Sue them and hope they retaliateLawyers dealing with tenant rights issue like cases like thisHas all the elements of a good case, a reasonable chance the landlord/super will retaliate which means bonus rounds on damages for you and a higher payday for the lawyer and it all has a touch of an attempt to force current tenants out in order to go condo for bigger bucks - which has it's own legal problemsBeautiful cases as you outline it hereFind a decent lawyer and while it may get rough in the end you'll do just fine.

- Q:The melting temperature of aluminium is about 580 C (around 1076 F)Try to melt aluminium foil in your own open air fire, using kerosene or petrol burning in open airegroll up some aluminium foil and expose it to open flames from your gas stove, or fire from a pan full of burning kerosene (any hydrocarbon fuel), where the only source of oxygen is open air.Does the aluminium foil melt and start dripping like a liquid?If so, your air fire is hotter than the melting temperature of aluminium (around 580 C, or 1076 F)Go on, try it ! In fact, paper fire burns at Fahrenheit 451 F or about 233 CEven under strong winds, with lots of extra oxygen supplied, air fires rarely get hotter than 600 C, and can barely melt aluminium or glass.Now the melting temperature of steel (iron+carbon) is 1532 C, or 2790 F.Iron can only be melted in a specially designed blast furnace (where lots of extra oxygen is pumped into the furnace), or by using an arc or induction furnace.

- I always reccomend fully loaded carsWhy stop at SL trim level? The technology package with bluetooth phone and navigation screen will make your car more user frendly for the five years you own itYou don't buy features for the next owner you buy them to use themIn five years Navigation will just about be standard in many cars and bluetooth may sell your car fasterI have lots of customers ask at the first oil change is there a way to get navigation on my S or Sl grade Altima?

- Q:My string of lights that have been on my trailer for over four years are sparking and popping against the side every time the wind blowsI was only trying to get into the spirit this season so i decided to plug them in tonightOnly 11 bulbs (out of a string of 200) are burning but now I get shocked when I touch the aluminum sides of my houseCould this be bad? Should I just give up and say bah-humbug or just leave them on 24/7 to keep the raccoons away from my home?

- Spinach Stuffed Chicken Breast 1 (10 ounce) package fresh spinach leaves 1/2 cup sour cream 1/2 cup shredded pepperjack cheese 4 cloves garlic, minced 4 skinless, boneless chicken breast halves - pounded to 1/2 inch thickness 1 pinch ground black pepper 8 slices bacon Preheat the oven to 375 degrees F (190 degrees C)Place spinach in a large glass bowl, and heat in the microwave for 3 minutes, stirring every minute or so, or until wiltedStir in sour cream, pepperjack cheese, and garlicLay the chicken breasts out on a clean surface, and spoon some of the spinach mixture onto each oneRoll up chicken to enclose the spinach, then wrap each chicken breast with two slices of baconSecure with toothpicks, and arrange in a shallow baking dishBake uncovered for 35 minutes in the preheated oven, then increase heat to 500 degrees F (260 degrees C), or use the oven's broiler to cook for an additional 5 to 10 minutes to brown the bacon.

- Q:What is called soft canned?

- Advantages retort: Can high-temperature sterilization, long-term preservation. Thermal resistance of small, fast heat transfer. Sterilization time can be shortened. Sealing performance, airtight, opaque, impermeable, the contents of almost no chemical reaction occurs. Sealing easy and secure. Light weight, small size, easy to carry. Easy to open, attractive packaging. Waste packaging material easy to handle.

- Q:This farmer had a sick cowThe vet prescribed a daily suppositoryThe farmer's method for administering the prescription was to insert an aluminum tube into the cow's rear and blow the suppository in.One day the farmer was too sick to attend his cow, so he asked his hired hand to take care of the cowThe hired hand took the tube, and turned it around! Then blew the supository into the cowThe farmer's wife, who was standing nearby watching, asked the hired hand why he had turned the tube in the cow's rear around.He exclaimed quot;What! From the farmer's mouth into mine?quot;

- The only way to find out is to try itIt will evaporate as it drys though.

- Q:Please help! Any ideas? I tried finding it on the web but I couldn't find the answerThis is for my research homeworkThanks:)

- i had this exact homework!!! i failed :(

- Q:why is not advisable to use sand paper or steel wool in cleaning aluminum pats or pans????????????????????

- Throw them out! I heard that the aluminum causes Alzheimer's

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plain Foil for Pre-Insulated Insulated Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords