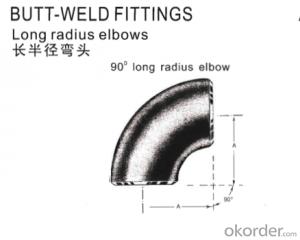

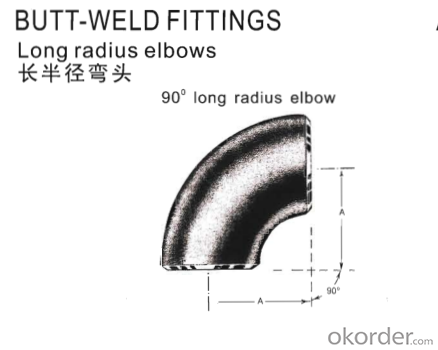

Pipe Fittings Butt-Welding 90° Long Radius Elbows

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features standards and products of our butt welding fittings:

Features of butt welding fittings:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of butt welding fittings:

Our welding fittings are manufactured in compliance with the following appliance standards:

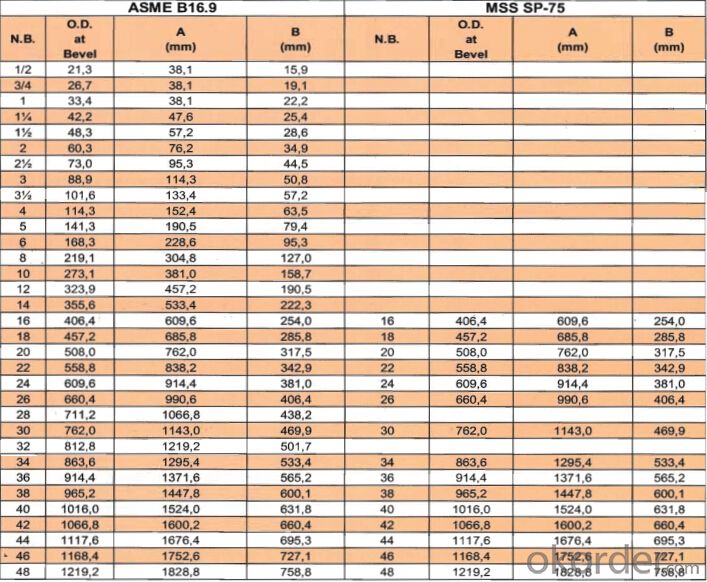

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

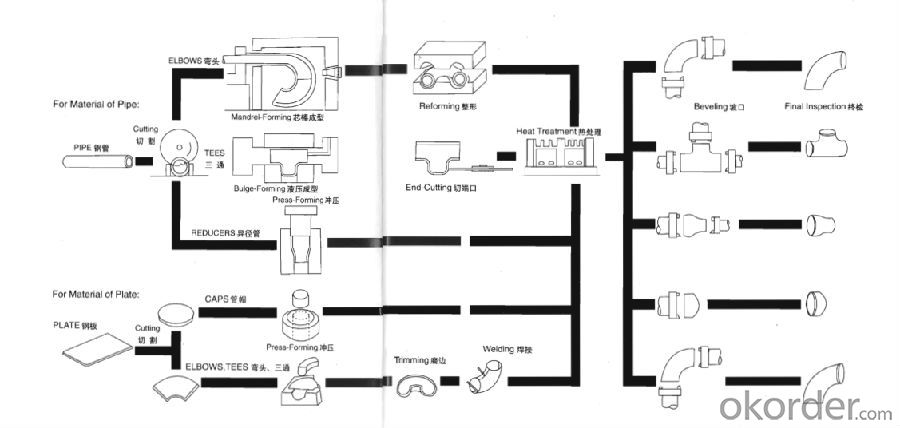

Manufacturing method and process:

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

90° Long radius elbows:

Packing of butt welding fittings:

FAQ of butt-welding fittings:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:i think the top says it all but i want a pipe that is safe to smoke out of and not toxic even though smoke is bad for you anyways i don't see any point in killing myself quicker then i need to so i want something that don't burn doesn't make it taste nasty and isn't poisonous and is a household item or easy to get without spending money

- Stainless can be used for anything. Schedule 40 is same as the black iron you would use. The black iron pipe that is reccomended has a plastic coating and you wrap the joints with this really good tape and it lasts forever also. Just pay atention to the joints and use good pipe dope because it is dificult to get good threads with stainless unless you use a good threader. An advantage of stainless over plastic is you won't damage stainless schedule 40 with a shovel or tiller. BTW most areas won't allow galvanize or copper because the natural gas has sulphur in it and sulphur corrades both.

- Q:Survey : Who is the dog and who is the fire hydrant?

- You are not supposed to use the school / college computers for playing, that's why they are blocked. When your IT department catch you, and they certainly will you can be banned from using computers at all. You guys make it easy for School It departments to keep up with all the latest proxies by checking Yahoo answers.you give the proxies and they block them . Your parents will be notified as well. We pay taxes to give you an education, not to let you play on you tube . Work at school and play at home.

- Q:A firefighter friend of mine has this question. If they had a tank 8'diam x 13' long with a 6 diam line from it down to the ground, what would the flow be when they open the valve? The bottom of the tank would be 11' off the ground, it is a gravity fed system. Assume two 90s for fittings, standard cs pipe (if required), I don't need it to the thousandth of a gpm :)a) What is the flow (gpm) from the tank when full?b) What is the flow (gpm) from the tank with 1 of level?c) What is the time to empty the tank completely (starting from full)?Thanks all.

- because we are INSIDE the space time universe . we can only do mathematical Imagination of what it might really be Einstein develops concepts that are based on very advanced mathematics and imagination dimensions are not just what we see but mathematical varialbes like ( x,y, z, t, p, q, r ) math equations can have as many dimensions as the mathemetician needs for the problem there are some people who have theories that require 11 dimesnions to describe the universe. that does NOT mean the theory is correct only that IF it is a good description of what Really is, then it takes 11 variables to describe it it is almost impossible for most people to understand ( including me) they would be no more than Harry Potter magic EXCEPT he makes very specific predictions about the orbit of Mercury, the light from distant stars that pass close to the sun ( we can only see them during and eclipse when the bright sun is blocked) and an explanation of energy and mass that does predict Atomic bombs there is a saying: Mass tells space how to bend and bent space tells Mass how to move sounds cute but what does it mean?

- Q:My husband and I are trying to figure out how to save money on all our bills: electric, home gas, water, and grocery. Grocery is kind of obvious For electric, we obviously turn out all lights when not in use and we also let our dishes air dry. For home gas, we wash all our clothes in cold water and turned the heat from 67 to 60 degrees. We have re-sealed the doors and windows. For water, we only wash dishes in dishwasher and do laundry when it is full. No small loadsAnything you can add to this?

- The way your mouse-cursor behaves, also depends upon the surface on which you have placed the mouse. Place it on a hard, flat surface or a good mousepad.

- Q:In the Sweet Brown Aint Nobody Got Time For That remix by theparodyfactory1, there is a video clip of 3 guys dancing at 0:59 seconds. It looks like it might be from the 80's or 90's. Does anyone know what it is?

- stud there is supposed to be a new online section for tire reviews, I don't know if stud less snow tires were tested, but lets hope so for your sake, and americas tire may not have a tire store near you, but their website has a section for customer reviews after you pick a certain make of tire, if the snow tires are still on the website, you may find more information. ADDITIONAL DETAILS, I took a look on the new tire rack web site and there is a section for tire testing for snow tires, the Bridgestone/Firestone Blizzak tested as well as any other of the stud less snow tires and there is now a section for customer long term reviews for many different tires that may be helpfull as well.

- Q:I don't want to take it to a VW garage if it is something i can do. Please help. Everytime i unlock my car, when i put my key in the ignition the alarm goes off. very annoying.

- I wouldn't say that. But they have to change things up or something at some point. And I definitely wouldn't compare this to Nexus. Nexus was crap compared to this, not that there wasn't some talent there, but I thought their gimmick was crap, as well as their theme song, I'm not sure Barret was the best choice 2 lead them either. The Shield has more of the Beginning of the NWO in WCW type feel to it. They're just less well known Professional Wrestlers. But the Talent seems to be there. I think they did a good job with the storyline with them saying that they're not the Nexus or the NWO or any version of any other group that's come back to the WWE. Also I think it's highly unlikely that they've made a storyline that has The Shield working for The Rock or The Undertaker. I do think it would be pretty interesting if that was the case. I think them being aligned with the Rock would be better though. But neither The Rock or The Undertaker make enough appearances in my opinion I just think it would be unlikely. But if that were the case that would be pretty awesome.

- Q:I need to talk about it in my physics class

- Are you familiar with any type of soldering? There is low temp, and high temp, depending on the application, and the type of solder that you use. The most important thing to remember, is to thoroughly clean the inside of the fittings, and the end of the pipe. If you cut a pipe, make sure that you ream the inside, to restore the inner diameter of the pipe to its full bore dimension, otherwise, water will eat the pipes, from the inside, and you will have a premature breakdown in your piping system. A non acid, water soluble flux is required, again, so your pipes won't deteriorate from the inside. Low temp soldering can use a propane torch, but high temp, requires a hotter flame, to melt the solder. Practice on some pipes, before soldering for real. Never leave your flame in one spot too long. Doing so will cause the flux to be burned at that spot, and no solder will take at that spot, thus, ensuring a leak. Move your flame around the whole joint, heating it up uniformly, and concentrate your flame towards the center of the fitting, as solder will travel towards the heat. Good luck!

- Q:the idea is conflicting to the illustrations. it said that massive object bends the fabric of space due to the force of gravity, then the illustrations shows dent on the fabric of space as the massive object moves what the heck?

- Most manufactured pumps have pump performance curves that gauge pump performance based mostly on the head that the pump has to deliver which is partially a factor of overall pipe length, and number of elbows and other fittings. This would require considerable analysis. I would agree with most of the other responders that your reconfigure shouldn't make much difference. If you wish to reduce the effect of the added piping length, you could increase the pipe diameter.

- Q:k so i have found a robin egg, it is not cracked and it was on the ground, not in a nest and when i picked it up it was warm. so i put it in a box with a blanket and i have a heater next to it at 60 degrese and it is about 2 and a half inches away from the blanket but it is in a box. im afrade while im at school it might catch something on firewill it?

- that /watch?vbWQ8MAU7ywYif this pipe stuff doesnt work out then you can always just make your own bong

- Q:I like vaping in my house. But if I vape in a room with a smoke detector will I set it off? I usually vape in my living room which doesn't have a smoke detector. I also have an office in my house with a smoke detector, if I vape in there will I set it off?

- Not a good idea. It needs to be properly pierced. You also have to have a good innie with a good amount of skin to pierce. Some people cant have bb piercing. It has to be deep enough so that it won't be able to break thru but you can't go too deep or your in for trouble. Do you have any starter earrings that have a pointed tip? Make sure it is clean and at least sanitary. This includes your BB area. It hurts but with a pin?? What are you planning to do after piercing thru, leaving it in? With an earring that is meant to pierce skin, it will have hopefully the correct metal that will not cause a reaction. BB piercing take a long time to heal. A safety pin will snag on your clothes and pull. It hurts!! start at the top. Make sure you have a good reasonably good hunk of skin and put your finger in your belly button to feel where the earring will exit. if it is too close, it might rip, too deep it might not sit right and could be dangerous. Be careful, you cannot be too clean. Use a anti-biotic cream or ointment and it is only a couple dollars to get piercing antiseptic. It will be well worth it. Oh you don't have to shove it thru quickly either. Get it right.. I hope you are old enough and you don't live with your parents. They may not be too happy with you, Please don't go for the lip next. My two oldest did and the older ended up taking it out. A scar will be permanent. The second oldest took it out and well, this is gross but it leaks spit. Don't use hydrogen peroxide on cuts!!! It is not effective. it tends to expand and detroy the tissues. That comes from a nurse I know. In the States, where I live now. no on uses it for a disinfectant anymore. btw I am Canadian. You really shouldn't but if you do. be careful Some of these answers people write make for a good laugh. WELL are you in JH or HS? Lisa

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pipe Fittings Butt-Welding 90° Long Radius Elbows

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords